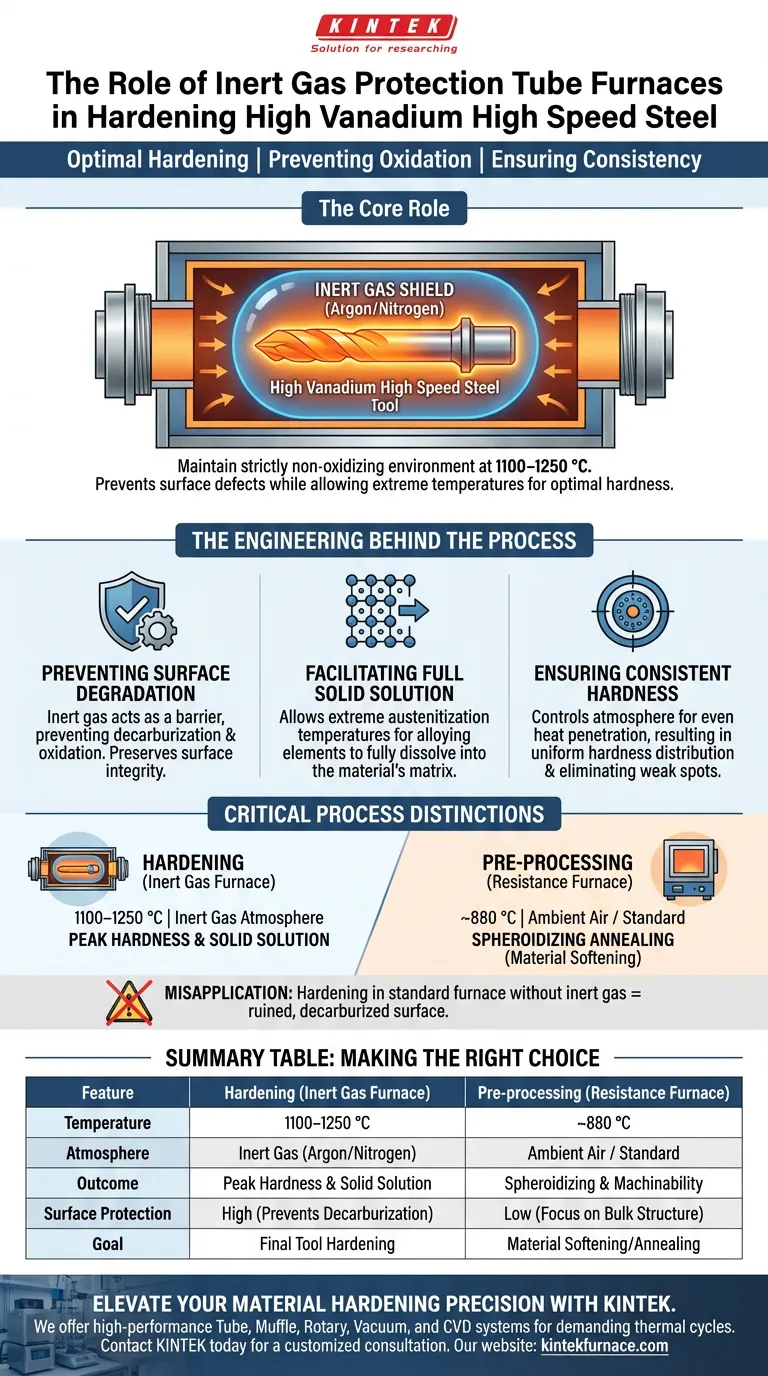

The primary role of an inert gas protection tube furnace is to maintain a strictly non-oxidizing environment during the high-temperature hardening phase of High Vanadium High Speed Steel. By introducing inactive gases during the austenitization process (typically between 1100–1250 °C), the furnace creates a shield that prevents surface defects while allowing the material to reach the extreme temperatures required for optimal hardness.

High Vanadium High Speed Steel requires intense heat to unlock its hardening potential, which makes it highly vulnerable to atmospheric reactions. The inert gas furnace shields the material from oxygen, ensuring the steel reaches its peak hardness without suffering from surface degradation.

The Engineering Behind the Process

Preventing Surface Degradation

The most immediate function of the inert gas environment is the prevention of surface decarburization and oxidation.

At the requisite hardening temperatures of 1100–1250 °C, unprotected steel reacts aggressively with oxygen. This reaction strips carbon from the surface (decarburization), leaving a soft outer layer that ruins the tool's effectiveness. The inert gas acts as a barrier, neutralizing this threat and preserving the surface integrity.

Facilitating Full Solid Solution

To achieve the characteristic hardness of High Vanadium High Speed Steel, the alloying elements must be fully dissolved into the material's matrix.

This process, known as solid solution, requires the high austenitization temperatures mentioned above. The inert gas furnace allows operators to hold the steel at these extreme temperatures for the necessary duration without fear of damaging the material's surface chemistry.

Ensuring Consistent Hardness

The ultimate goal of using this specific equipment is uniformity.

By controlling the atmosphere, the furnace ensures that the heat treatment penetrates evenly and chemically affects the steel as intended. This results in a consistent hardness distribution after quenching, eliminating weak spots that could lead to tool failure.

Critical Process Distinctions

It is vital to distinguish between the furnaces used for hardening versus those used for preparation (annealing).

Hardening vs. Annealing Environments

While the inert gas furnace is essential for the high-temperature hardening phase, other equipment like periodic resistance furnaces serve a different purpose.

Resistance furnaces are typically used at lower temperatures (around 880 °C) for spheroidizing annealing. This process softens the material to improve machinability and prepares the microstructure for the eventual hardening in the inert gas furnace.

The Consequence of Misapplication

Attempting to harden High Vanadium High Speed Steel in a standard resistance furnace without inert gas protection is a common pitfall.

While a standard furnace can achieve the temperature, it cannot control the atmosphere. This would result in a tool that is technically "hardened" internally but has a ruined, decarburized surface that requires excessive grinding to fix.

Making the Right Choice for Your Goal

To achieve high-performance results with High Vanadium High Speed Steel, you must align the equipment with the specific stage of heat treatment.

- If your primary focus is Hardening (Austenitization): You must use an inert gas protection tube furnace to reach 1100–1250 °C without causing decarburization or oxidation.

- If your primary focus is Pre-processing (Annealing): A periodic resistance furnace is sufficient for holding the material at 880 °C to spheroidize carbides and improve machinability.

Success lies in using the inert atmosphere to decouple the benefits of high heat from the damages of oxidation.

Summary Table:

| Feature | Hardening (Inert Gas Furnace) | Pre-processing (Resistance Furnace) |

|---|---|---|

| Temperature Range | 1100–1250 °C | ~880 °C |

| Primary Atmosphere | Inert Gas (Argon/Nitrogen) | Ambient Air / Standard |

| Key Outcome | Peak Hardness & Solid Solution | Spheroidizing & Machinability |

| Surface Protection | High (Prevents Decarburization) | Low (Focus on Bulk Structure) |

| Main Goal | Final Tool Hardening | Material Softening/Annealing |

Elevate Your Material Hardening Precision with KINTEK

Don't compromise the surface integrity of your High Vanadium High Speed Steel. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to handle the most demanding thermal cycles. Whether you need standard lab equipment or a custom high-temperature furnace, our solutions ensure consistent, oxidation-free results for your unique research and production needs.

Ready to optimize your heat treatment process? Contact KINTEK today for a customized consultation and let our experts help you choose the perfect furnace for your application.

Visual Guide

References

- Yujie Wang, Haochun Xia. Investigation on microstructure, mechanical properties, and tribological behaviors of spray-formed high-vanadium high-speed steel after heat treatment. DOI: 10.1007/s44251-024-00061-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is it necessary to introduce high-purity nitrogen during tube furnace calcination? Ensure High-Performance La-EPS-C-450

- What is a vertical tube furnace? Leverage Gravity for Superior Material Processing

- What are the advantages of decomposing tube furnaces? Achieve Precise Control and High Efficiency in Thermal Processes

- What protective role does a wet hydrogen (Ar/H2) environment play in a tube furnace for thin film stability testing?

- Why is a high-precision gas flow control system required for vermiculite heat treatment? Ensure Perfect Atmosphere

- What makes tubular furnaces versatile and precise? Unlock Superior Thermal Processing Control

- How does a high-temperature tube furnace facilitate the synthesis of Ni17W3/MoO3-x/WO3-x catalysts during annealing?

- How does a tube furnace work? Master Precise Heat and Atmosphere Control