At its core, maintaining a horizontal electric furnace involves a disciplined routine focused on four key areas. These include the regular calibration of temperature sensors, thorough cleaning to prevent sample contamination, proactive monitoring of heating element wear, and verification of the processing atmosphere, whether it be gas or vacuum.

The goal of furnace maintenance is not simply to prevent failure, but to guarantee the accuracy, repeatability, and safety of your thermal processes. It transforms the furnace from a piece of hardware into a reliable and precise scientific instrument.

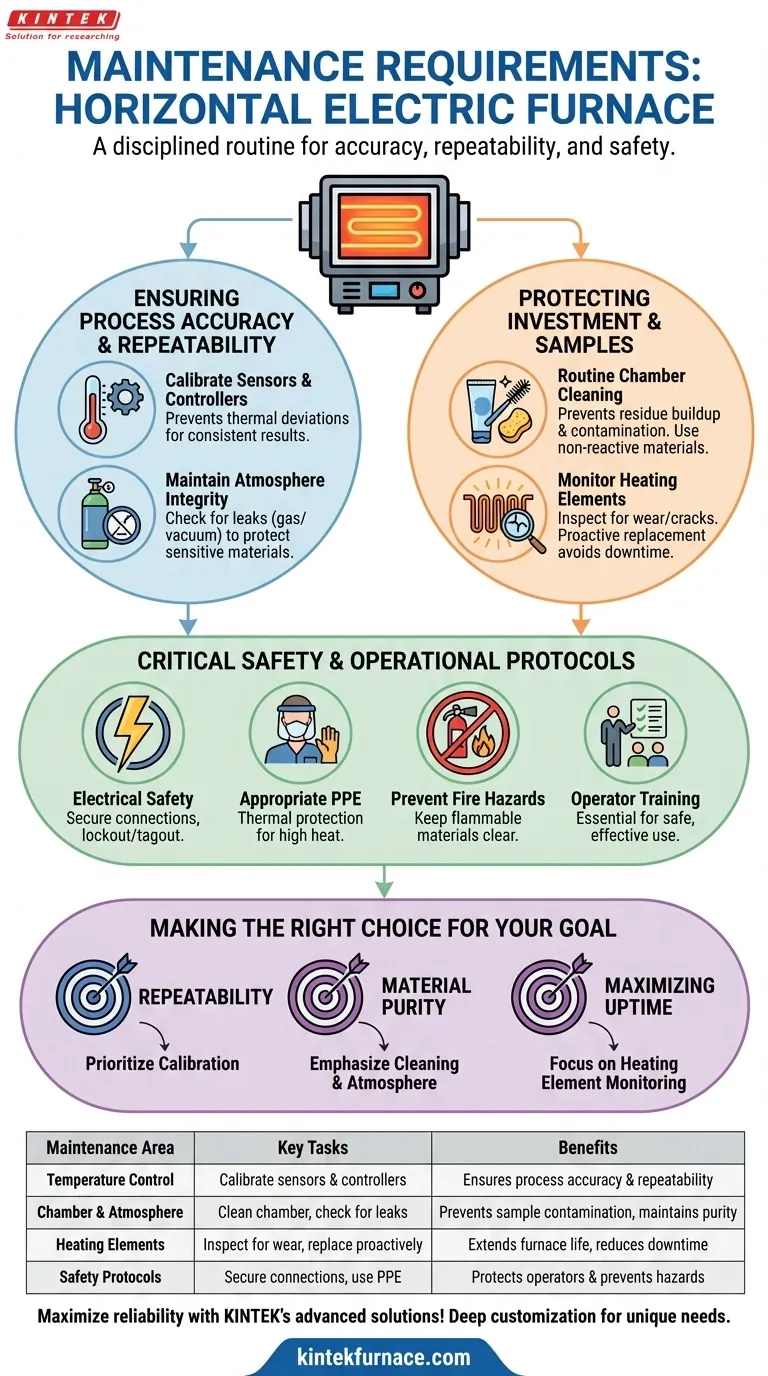

Ensuring Process Accuracy and Repeatability

The primary function of your furnace is to deliver precise thermal control. Maintenance is what ensures that precision is not compromised over time.

Calibrating Temperature Sensors

Periodic calibration of temperature sensors and their associated controllers is non-negotiable. Even minor thermal deviations can significantly alter the properties of your materials, compromising your results.

Regular calibration ensures that the temperature you set is the temperature your sample experiences, maintaining accuracy across countless processing cycles.

Maintaining Atmosphere Integrity

For furnaces using controlled atmospheres, atmosphere integrity is paramount. This involves checking for leaks in gas delivery lines or vacuum pump systems.

This step is especially critical when processing oxidation-sensitive materials, as even a small leak can introduce contaminants and ruin the sample.

Protecting Your Investment and Samples

Proper maintenance directly extends the operational life of the furnace and prevents the loss of valuable materials and time.

Routine Chamber Cleaning

Operators must clean the furnace chamber regularly. Over time, residue from previous cycles can build up inside the tube.

This residue can vaporize during subsequent runs, creating an unintended and uncontrolled atmosphere that contaminates your samples. Always use non-reactive cleaning materials to avoid introducing new contaminants.

Monitoring Heating Element Wear

Heating elements are consumable components that degrade with use. Visually inspect the elements for signs of wear, cracking, or discoloration.

Proactive monitoring allows you to replace elements before they fail catastrophically, preventing costly emergency repairs and unscheduled downtime.

Critical Safety and Operational Protocols

A well-maintained furnace is a safe furnace. Integrating safety checks into your maintenance routine is essential for protecting operators and your facility.

Adhering to Electrical Safety

These are high-power systems. Always ensure all electrical connections are secure and panels are properly closed. Follow standard lockout/tagout procedures during any internal maintenance.

Using Appropriate Protective Gear

Operators must use personal protective equipment (PPE) suitable for high-heat environments. This includes thermal gloves and face shields, especially when loading or unloading the furnace.

Preventing Fire Hazards

Keep the area surrounding the furnace clear of all flammable materials. This simple housekeeping rule is a critical fire prevention measure.

The Importance of Operator Training

The best maintenance plan can be undermined by improper use. Ensure all operators are thoroughly trained on the furnace's specific operating procedures, safety features, and emergency protocols.

Making the Right Choice for Your Goal

Your maintenance schedule should reflect your most critical objectives.

- If your primary focus is process repeatability: Prioritize rigorous calibration of temperature sensors and controllers.

- If your primary focus is material purity: Emphasize meticulous chamber cleaning and verification of atmosphere integrity.

- If your primary focus is maximizing uptime: Implement a proactive schedule for monitoring and replacing heating elements.

Consistent maintenance empowers you to have full confidence in your equipment and the results it produces.

Summary Table:

| Maintenance Area | Key Tasks | Benefits |

|---|---|---|

| Temperature Control | Calibrate sensors and controllers | Ensures process accuracy and repeatability |

| Chamber and Atmosphere | Clean chamber, check for leaks | Prevents sample contamination, maintains purity |

| Heating Elements | Inspect for wear and replace proactively | Extends furnace life, reduces downtime |

| Safety Protocols | Secure electrical connections, use PPE | Protects operators and prevents hazards |

Maximize your furnace's reliability with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control