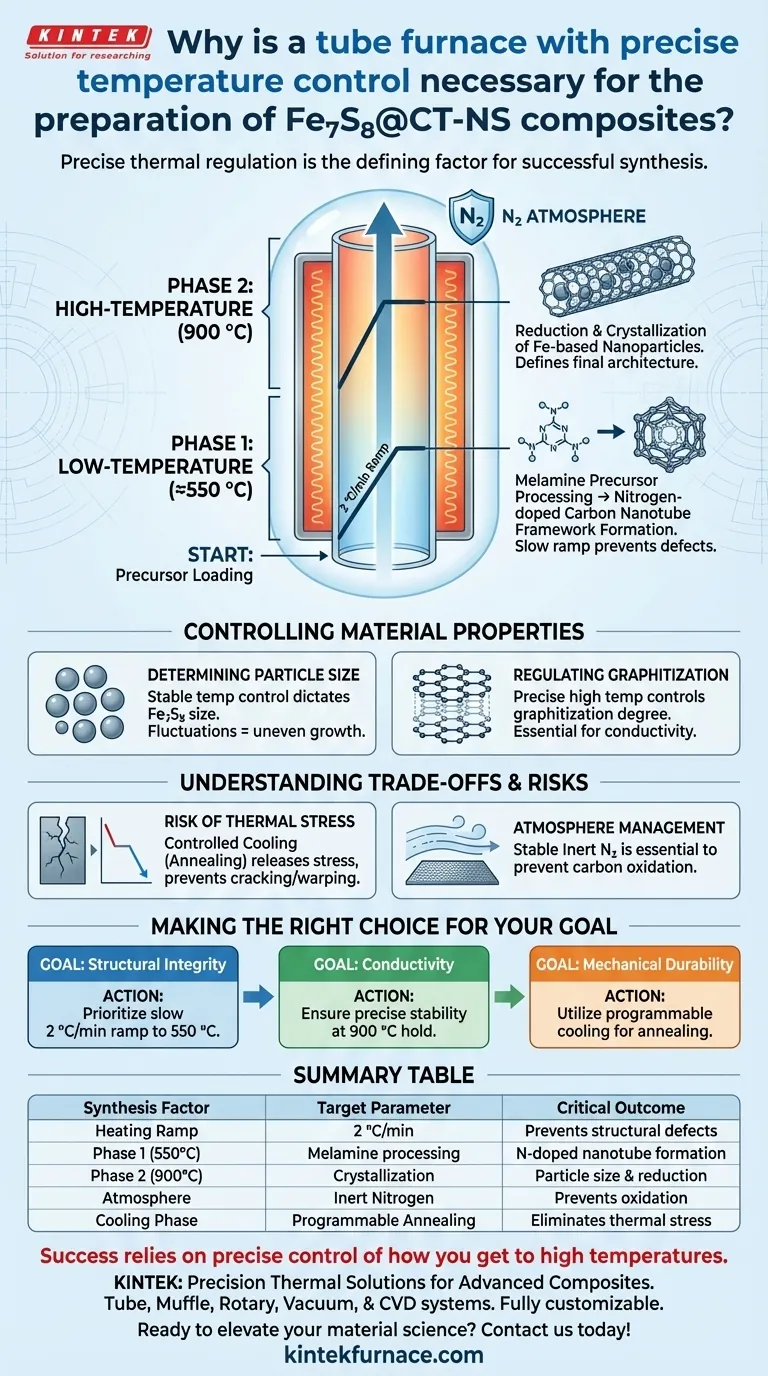

Precise thermal regulation is the defining factor in the successful synthesis of Fe7S8@CT-NS composites. A tube furnace is strictly necessary to execute a specific programmable heating ramp—typically 2 °C/min—which facilitates a complex, multi-stage chemical transformation under a protective nitrogen atmosphere.

The tube furnace acts as a programmable reactor that separates distinct chemical phases. It ensures the carbon framework is built at lower temperatures before the iron-based core crystallizes at higher temperatures, defining the material's final architecture.

Managing the Dual-Stage Synthesis

The Low-Temperature Phase (550 °C)

The preparation of this composite is not a single-step reaction. You must first reach an intermediate temperature of roughly 550 °C to process the melamine precursor.

At this specific stage, the precise heating rate ensures the melamine is directionally converted into a nitrogen-doped carbon nanotube framework. If the temperature ramps too quickly, this structural framework may fail to form correctly.

The High-Temperature Phase (900 °C)

Once the framework is established, the furnace must ramp up to 900 °C. This higher tier is required for the reduction and crystallization of the iron-based nanoparticles.

The tube furnace allows these two distinct processes—framework formation and metal crystallization—to occur sequentially in the same reactor without manual intervention.

Controlling Material Properties

Determining Particle Size

The ultimate size of the Fe7S8 nanoparticles is dictated by the stability of the temperature control.

Fluctuations in heat or ramp rates can lead to uneven particle growth, which compromises the composite's consistency.

Regulating Graphitization

The degree to which the carbon matrix becomes graphitized is directly controlled by the precision of the furnace at high temperatures.

Proper graphitization is essential for the electrical conductivity and mechanical stability of the final composite material.

Understanding the Trade-offs

The Risk of Thermal Stress

While the primary focus is often on heating, controlled cooling is equally critical.

Rapid temperature drops can create residual thermal stresses due to differences in thermal expansion coefficients between material layers. Programmable cooling (annealing) helps release this stress, preventing the finished product from cracking or warping.

Atmosphere Management

A standard oven cannot provide the necessary environment for this synthesis.

The tube furnace is essential for maintaining a stable inert atmosphere (Nitrogen) throughout the entire 2 °C/min ramp. Without this protection, the carbon components would oxidize and degrade rather than form a nanotube framework.

Making the Right Choice for Your Goal

To optimize your synthesis of Fe7S8@CT-NS, adjust your furnace parameters based on your specific performance targets:

- If your primary focus is Structural Integrity: Prioritize a slow, steady ramp rate (2 °C/min) through the 550 °C phase to ensure the carbon nanotube framework forms without defects.

- If your primary focus is Conductivity: Ensure precise temperature stability at the 900 °C hold time to maximize the degree of graphitization in the carbon matrix.

- If your primary focus is Mechanical Durability: utilize programmable cooling to anneal the material and relieve internal thermal stresses before reaching room temperature.

Success in this synthesis relies not just on reaching high temperatures, but on the precise control of how you get there.

Summary Table:

| Synthesis Factor | Target Parameter | Critical Outcome |

|---|---|---|

| Heating Ramp | 2 °C/min | Prevents structural defects in carbon framework |

| Phase 1 (550°C) | Melamine processing | Formation of Nitrogen-doped carbon nanotubes |

| Phase 2 (900°C) | Crystallization | Particle size control & reduction of Fe7S8 |

| Atmosphere | Inert Nitrogen | Prevents oxidation of the carbon matrix |

| Cooling Phase | Programmable Annealing | Eliminates thermal stress and prevents cracking |

Precision Thermal Solutions for Advanced Composites

Unlock the full potential of your Fe7S8@CT-NS synthesis with KINTEK’s high-precision thermal equipment. Backed by expert R&D and world-class manufacturing, we provide high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for researchers who demand perfection.

Whether you need strictly controlled 2 °C/min ramps or stable inert environments, our furnaces are fully customizable to meet your unique laboratory needs.

Ready to elevate your material science? Contact us today to find your custom furnace solution!

Visual Guide

References

- Xingyun Zhao, Tiehua Ma. Fe<sub>7</sub>S<sub>8</sub> Nanoparticles Embedded in Sulfur–Nitrogen Codoped Carbon Nanotubes: A High‐Performance Anode Material for Lithium‐Ion Batteries with Multilevel Confinement Structure. DOI: 10.1002/celc.202500066

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a two-stage sintering process in a tube furnace contribute to high-performance sodium-ion battery cathodes?

- How does a laboratory tube furnace facilitate the sulfidation of Co3O4@CNT? Advanced Synthesis Secrets

- What critical conditions does a High-Temperature Tube Furnace provide for NiO-CNF? Master Hybrid Material Synthesis

- How do horizontal furnaces support the ceramics industry? Boost Performance with Precision Heat Treatment

- What are the key advantages of using a rotary tube furnace? Achieve Dynamic, Uniform Heating for Powders

- What role does a laboratory tube furnace play in the preparation of biochar from date stones? Optimize Pyrolysis.

- What is the role of programmed temperature control in a tube furnace? Optimize N-GC-X Catalyst Synthesis

- What is the recommended procedure for maintaining atmosphere purity in a vacuum tube experimental furnace? Ensure High-Purity Results