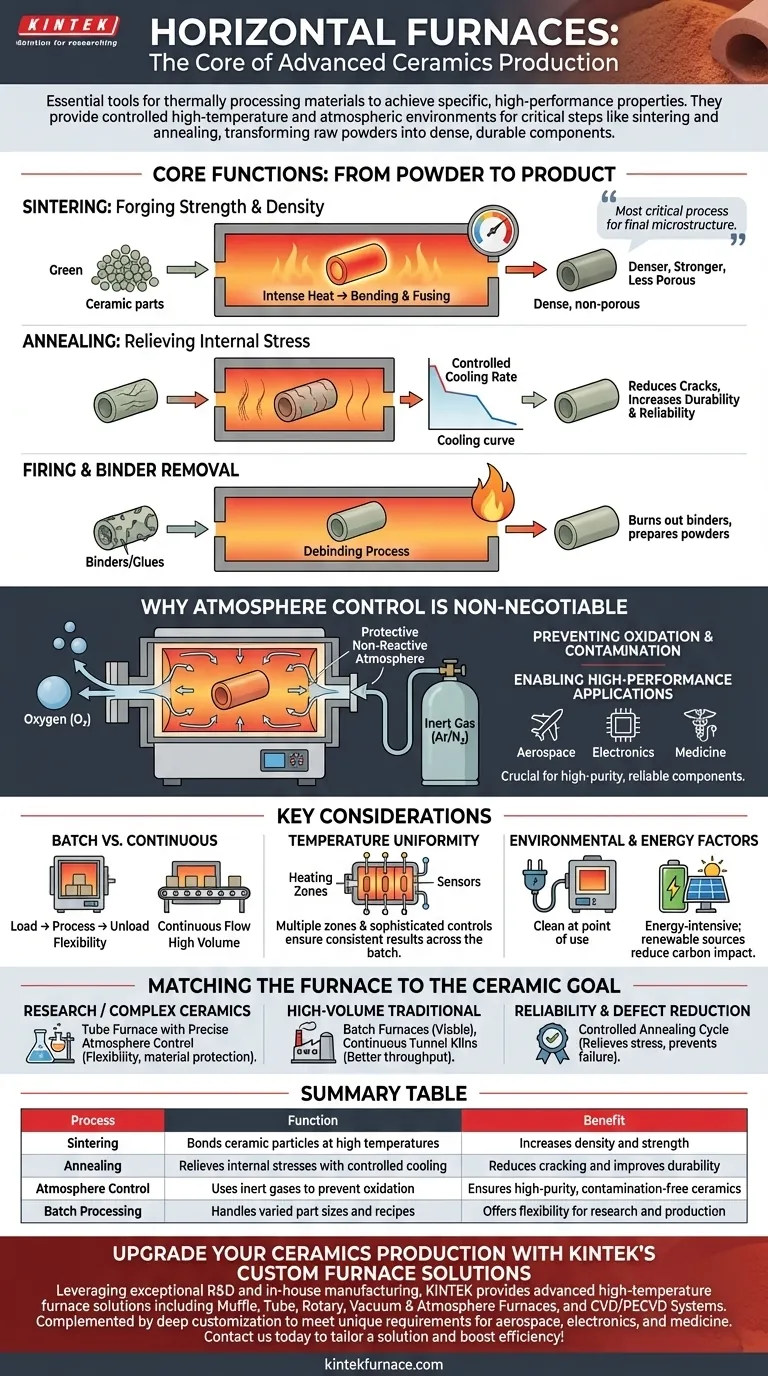

In the advanced ceramics industry, horizontal furnaces are essential tools for thermally processing materials to achieve specific, high-performance properties. They provide the controlled high-temperature and atmospheric environments required for critical manufacturing steps like sintering and annealing, which transform raw ceramic powders into dense, durable, and reliable finished components.

The true value of a horizontal furnace in ceramics is not just its ability to get hot, but its capacity to provide a precisely controlled environment. This control is what allows manufacturers to engineer the final material properties required for demanding applications in aerospace, electronics, and medicine.

The Core Functions: From Powder to Product

A horizontal furnace's primary role is to execute specific heat treatment processes that are fundamental to creating a ceramic part. These processes develop the material's final microstructure, which dictates its strength, hardness, and thermal resistance.

Sintering: Forging Strength and Density

Sintering is the most critical process. It involves heating formed ceramic parts (in their "green" state) to a high temperature, just below their melting point.

This intense heat causes the individual ceramic particles to bond and fuse, eliminating the pores between them. The result is a denser, stronger, and less porous final product.

Annealing: Relieving Internal Stress

Annealing is a heat treatment used to alter a material's properties. After initial firing or shaping, a ceramic component can contain internal stresses.

By heating the component in a furnace and then carefully controlling the cooling rate, these stresses are relieved. This reduces the risk of future cracks or catastrophic failure, making the part more durable and reliable.

Firing, Roasting, and Binder Removal

Furnaces are also used for general-purpose firing and roasting of ceramic powders to prepare them for manufacturing.

Additionally, they are used to burn out binders and other "glues" that hold ceramic powders in a specific shape before sintering. This process, often called binder burnout or debinding, must be done carefully to avoid damaging the part.

Why Atmosphere Control is Non-Negotiable

For many advanced technical ceramics, simply reaching a high temperature is not enough. The chemical composition of the atmosphere inside the furnace is just as important as the heat itself.

Preventing Oxidation and Contamination

At the extreme temperatures used in sintering, many ceramic materials will react with oxygen in the air. This oxidation can severely degrade the material's mechanical and electrical properties.

Inert atmosphere furnaces, a common type of horizontal furnace, prevent this by filling the heating chamber with a non-reactive gas like argon or nitrogen. This purges the oxygen and protects the ceramic part from unwanted chemical reactions and contamination.

Enabling High-Performance Applications

This precise atmospheric control is what makes it possible to produce high-purity, high-performance ceramics for industries like electronics, automotive, and aerospace.

Without it, manufacturing reliable ceramic insulators, wear-resistant components, or biocompatible implants would be impossible.

Understanding the Key Considerations

While incredibly useful, horizontal furnaces are not a universal solution. Understanding their operational context is key to using them effectively.

Batch vs. Continuous Processing

Horizontal furnaces are typically batch furnaces. This means a set quantity of parts is loaded, processed, and then unloaded. This provides excellent flexibility for different part sizes and process recipes.

However, for very high-volume production of a single type of part, a continuous furnace (like a tunnel kiln) where parts move through different heat zones on a conveyor may be more efficient.

Temperature Uniformity

Achieving perfect temperature uniformity across the entire length of a horizontal furnace chamber can be a design challenge.

Well-designed furnaces use multiple heating zones and sophisticated controls to ensure every part in the batch experiences the exact same thermal profile, guaranteeing consistent results.

Environmental and Energy Factors

Modern electric horizontal furnaces produce no direct emissions at the point of use, making them a clean option for a workshop or factory floor.

They are, however, energy-intensive. Their overall environmental footprint is tied to the source of their electricity; pairing them with renewable energy sources can significantly reduce their carbon impact.

Matching the Furnace to the Ceramic Goal

Choosing the right thermal processing strategy depends entirely on your end goal.

- If your primary focus is research or producing complex technical ceramics: A horizontal tube furnace with precise atmosphere control is essential for flexibility and preventing material degradation.

- If your primary focus is high-volume production of traditional ceramics: Batch-style horizontal furnaces are a viable option, but continuous tunnel kilns may offer better throughput for standardized items.

- If your primary focus is ensuring part reliability and reducing defects: Implementing a furnace with a controlled annealing cycle is critical for relieving internal stresses that lead to failure.

Ultimately, mastering the horizontal furnace is about mastering the precise transformation of raw materials into ceramics with engineered, predictable performance.

Summary Table:

| Process | Function | Benefit |

|---|---|---|

| Sintering | Bonds ceramic particles at high temperatures | Increases density and strength |

| Annealing | Relieves internal stresses with controlled cooling | Reduces cracking and improves durability |

| Atmosphere Control | Uses inert gases to prevent oxidation | Ensures high-purity, contamination-free ceramics |

| Batch Processing | Handles varied part sizes and recipes | Offers flexibility for research and production |

Upgrade Your Ceramics Production with KINTEK's Custom Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in aerospace, electronics, or medicine, our furnaces deliver precise temperature and atmosphere control for sintering, annealing, and more—ensuring reliable, high-performance ceramics. Contact us today to discuss how we can tailor a solution for your specific needs and boost your manufacturing efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations