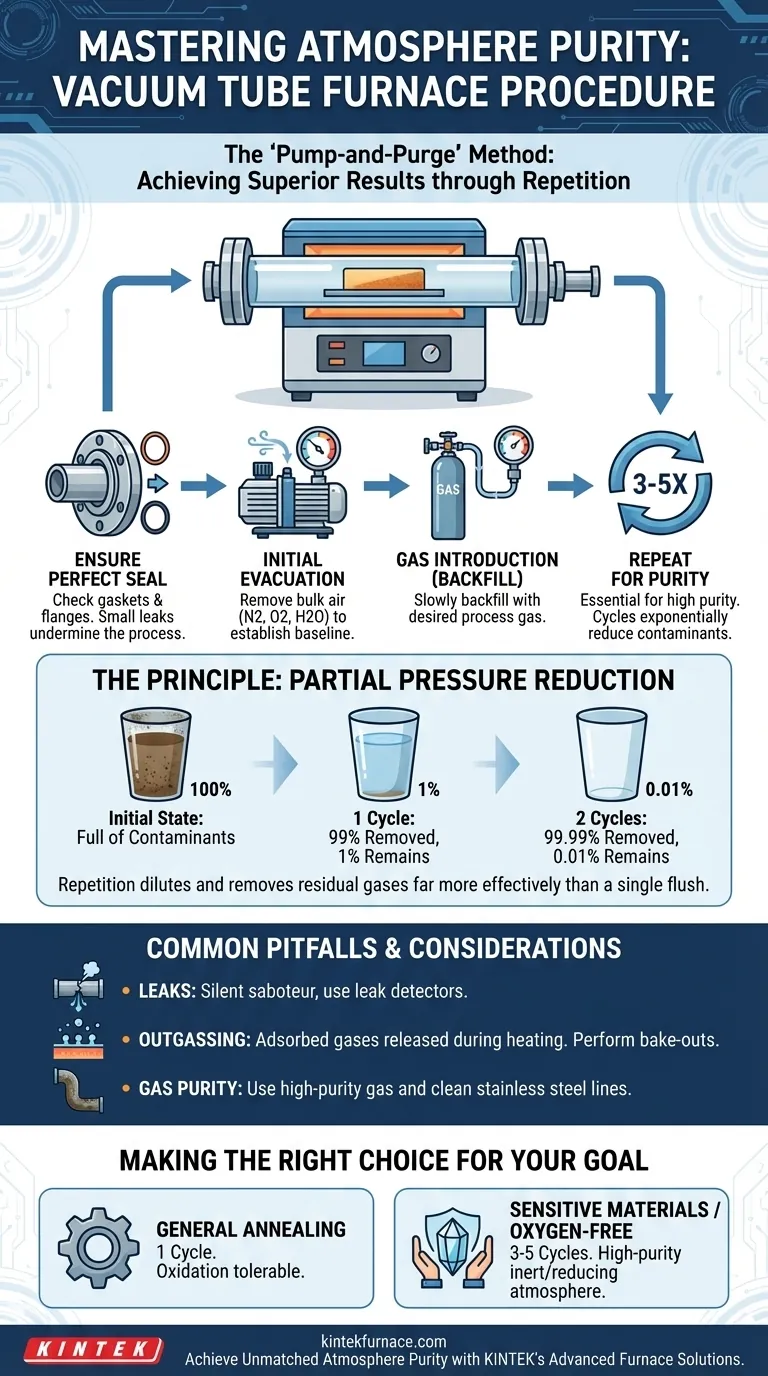

The recommended procedure for achieving high atmosphere purity in a vacuum tube furnace is to first evacuate the furnace tube using a vacuum pump and then introduce your desired process gas. For experiments requiring high purity, this "pump-and-purge" cycle should be repeated multiple times. This method systematically removes residual air and contaminants far more effectively than simply flowing gas through the tube.

The core challenge is not just replacing the air in the tube, but reducing the partial pressure of unwanted contaminants like oxygen and water vapor to negligible levels. A single purge is often insufficient; true purity is achieved through repeated cycles of evacuation and backfilling.

The Principle: Why Pumping and Purging is Essential

Simply flowing a process gas into the furnace tube is an unreliable method for achieving a pure atmosphere. It will mix with the existing air, and pockets of contaminants will remain, compromising your experiment, especially at high temperatures.

The Problem of Residual Contaminants

When you seal the furnace tube, it contains normal air, which is roughly 78% nitrogen, 21% oxygen, and trace amounts of other gases, including water vapor. Oxygen and water are highly reactive at elevated temperatures and can lead to unwanted oxidation or other side reactions with your sample material.

The Power of Partial Pressure Reduction

The pump-and-purge method works by systematically reducing the partial pressure of these contaminants. Each evacuation cycle removes a vast majority (e.g., 99% or more) of all gases present in the tube.

When you then introduce your high-purity process gas, the tiny fraction of remaining contaminants is diluted. The next evacuation cycle removes 99% of this new mixture, further reducing the contaminant level exponentially.

How Repetition Creates Purity

Think of it like rinsing a dirty cup. A single rinse with clean water helps, but some residue remains. Rinsing it three or four times, emptying it completely between each rinse, ensures it becomes exceptionally clean.

Each pump-and-purge cycle multiplies the purity. If one cycle removes 99% of the air, leaving 1% contamination, the second cycle removes 99% of that remaining 1%, resulting in only 0.01% contamination. A third cycle would reduce it to 0.0001%, and so on.

Understanding the Key Steps and Considerations

Executing the procedure correctly is just as important as understanding the principle. The integrity of your setup is the foundation for a pure atmosphere.

Step 1: Ensure a Perfect Seal

Before any pumping or purging, you must ensure the furnace tube is perfectly sealed. This involves correctly installing the stainless steel flanges and checking that all O-rings or gaskets are clean and properly seated. A small leak will continuously introduce contaminants and undermine the entire process.

Step 2: The Initial Evacuation

Connect the vacuum pump to the flange outlet and evacuate the tube. The goal is to remove the bulk of the air. The quality of your vacuum pump determines the baseline pressure you can achieve, which sets the stage for the effectiveness of your first purge.

Step 3: The Gas Introduction (Backfill)

Once a sufficient vacuum is reached, close the valve to the pump and slowly introduce your high-purity process gas through the air inlet. Do this carefully to avoid disturbing the sample material and to allow the pressure to equalize gently.

Step 4: Repeat for Purity

For any experiment sensitive to contamination, repeat steps 2 and 3. Closing the gas inlet, re-opening the valve to the vacuum pump, and evacuating the tube again will remove the vast majority of the residual contaminants diluted in the first purge.

Common Pitfalls to Avoid

Achieving a pure atmosphere is often a battle against unseen factors. Being aware of them is critical for reproducible results.

Leaks: The Silent Saboteur

The most common point of failure is a leak in the system, typically at the flange seals. Even a microscopic leak will constantly allow air to seep back into the tube, especially under vacuum. A vacuum gauge that fails to hold a steady low pressure is a clear sign of a leak.

Outgassing: The Hidden Contaminant Source

Outgassing is the release of adsorbed gases from the surfaces within the furnace, including the tube walls and your sample itself. Water vapor is a primary culprit. As you heat the furnace, this outgassing can increase, releasing contaminants into your carefully prepared atmosphere. Performing a "bake-out" (heating the system under vacuum) before introducing the process gas can help mitigate this.

Gas Purity and Plumbing

The purity of your final atmosphere can be no better than the purity of your source gas and the cleanliness of your gas lines. Use high-purity grade gas and ensure all tubing and valves between the gas cylinder and the furnace are made of appropriate materials (like stainless steel) and are free from contaminants.

Making the Right Choice for Your Goal

The required number of purge cycles depends entirely on the sensitivity of your experiment.

- If your primary focus is general annealing or sintering where some oxidation is tolerable: A single, thorough pump-and-purge cycle may be sufficient.

- If your primary focus is synthesizing oxygen-sensitive materials or preventing surface oxidation: Performing 3 to 5 pump-and-purge cycles is the standard recommendation for ensuring a high-purity inert or reducing atmosphere.

- If your primary focus is ultra-high purity applications like semiconductor research: You must employ multiple purge cycles in combination with system bake-outs and leak-checking with a dedicated detector.

Mastering this fundamental procedure is the key to ensuring the validity and reproducibility of your high-temperature experiments.

Summary Table:

| Step | Action | Key Consideration |

|---|---|---|

| 1 | Ensure Perfect Seal | Check O-rings and flanges for leaks to prevent contamination. |

| 2 | Initial Evacuation | Use a vacuum pump to remove bulk air; quality affects baseline purity. |

| 3 | Gas Introduction | Slowly backfill with high-purity gas to avoid sample disturbance. |

| 4 | Repeat Cycles | Perform 3-5 cycles for sensitive applications to exponentially reduce contaminants. |

| Common Pitfalls | Avoid Leaks and Outgassing | Use leak detectors and bake-outs to maintain purity. |

Achieve Unmatched Atmosphere Purity with KINTEK's Advanced Furnace Solutions

Struggling with contamination in your high-temperature experiments? KINTEK specializes in delivering high-performance vacuum tube furnaces and other systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs—ensuring reliable, reproducible results with superior atmosphere control.

Don't let impurities compromise your research—contact us today to discuss how our tailored solutions can enhance your lab's efficiency and success!

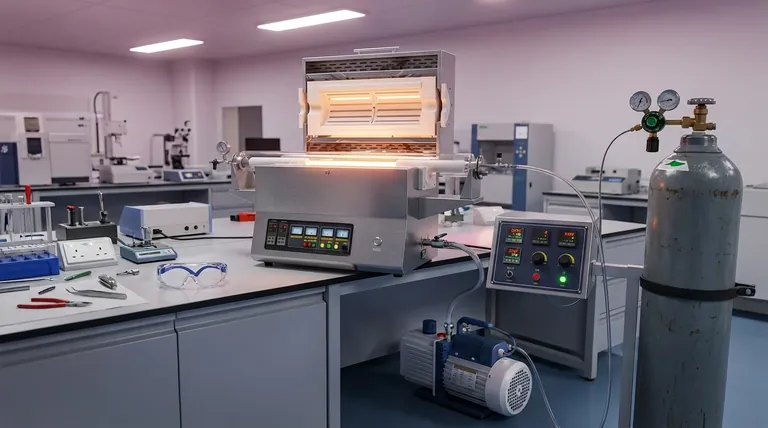

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation