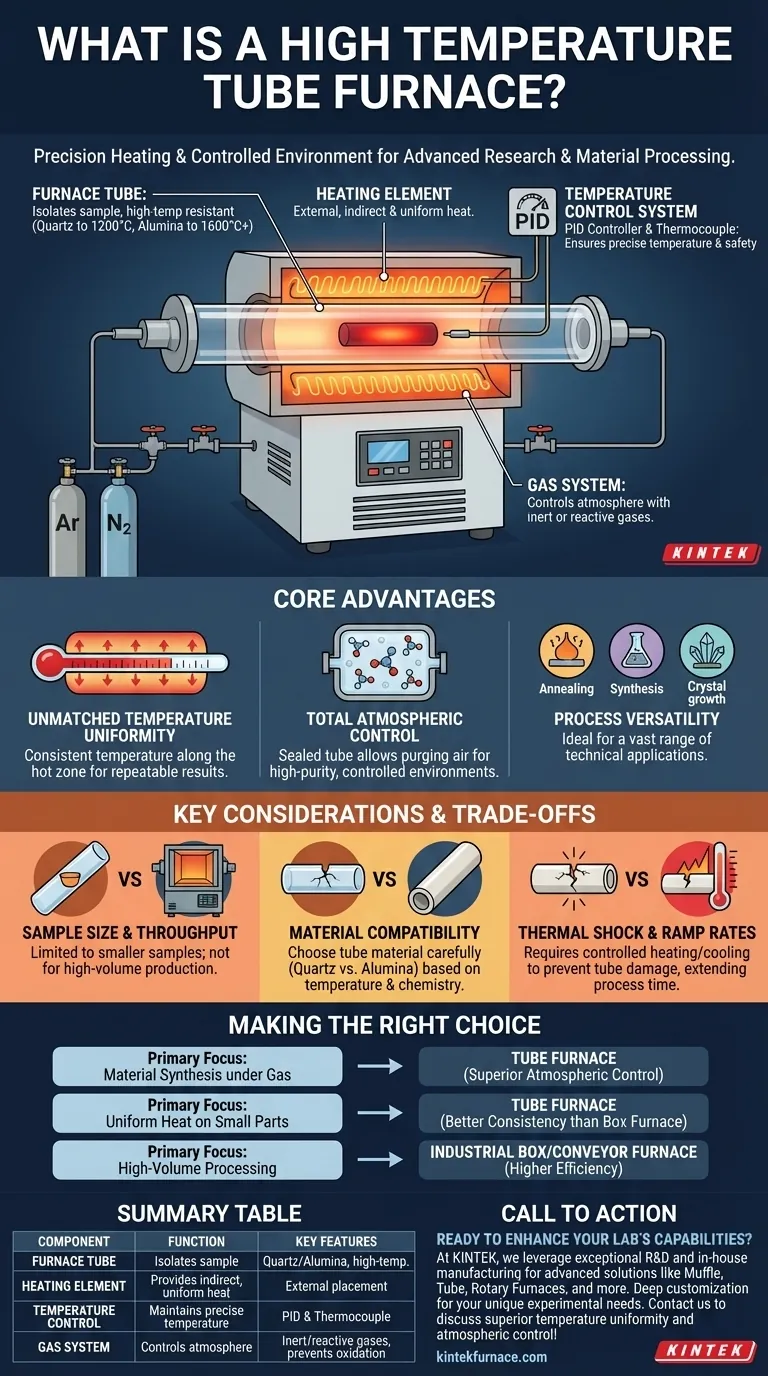

In essence, a high temperature tube furnace is a specialized piece of laboratory and industrial equipment designed for heating materials with exceptional precision. It consists of a cylindrical chamber, or "tube," that holds the sample, which is then heated externally by surrounding elements to achieve uniform and tightly controlled temperatures, often within a specific gas atmosphere.

The true value of a tube furnace is not just its ability to reach high temperatures, but its unique capacity to create a pure, controlled, and isolated environment. This combination of extreme heat and atmospheric control is what makes it an indispensable tool for advanced material processing and research.

Deconstructing the Tube Furnace: Key Components and Function

A tube furnace's design is deceptively simple, but each component plays a critical role in its performance and versatility.

The Furnace Tube: The Heart of the Process

The furnace tube is the core component where all the work happens. It isolates the sample from the heating elements and the outside environment.

These tubes are made from high-temperature-resistant materials, most commonly quartz or high-purity alumina ceramic. The choice depends on the required maximum temperature and chemical compatibility with the sample.

The Heating Element: Delivering Precise Thermal Energy

Heating elements, such as high-resistance wire or silicon carbide rods, are arranged around the outside of the furnace tube.

This external placement is key to providing indirect and uniform heat along the length of the tube's central "hot zone," ensuring the entire sample experiences a consistent temperature.

The Temperature Control System: Ensuring Accuracy and Safety

Modern tube furnaces use a sophisticated feedback loop to manage heat. A thermocouple placed near the tube constantly measures the temperature.

This data feeds into a PID (Proportional-Integral-Derivative) controller, which intelligently adjusts the power sent to the heating elements to maintain the set temperature with remarkable accuracy and prevent overshoot.

The Gas System: Creating a Controlled Atmosphere

Perhaps the most significant feature is the ability to control the atmosphere. Flanges and seals at the ends of the tube allow it to be connected to a gas delivery system.

This enables users to flow inert gases (like argon or nitrogen) to prevent oxidation, or introduce reactive gases to facilitate specific chemical processes like synthesis or reduction.

The Core Advantages: Why Choose a Tube Furnace?

While other furnaces can get hot, a tube furnace offers a unique combination of benefits that make it superior for many technical applications.

Unmatched Temperature Uniformity

Because the heating elements fully encircle the chamber, the temperature distribution along the sample is far more even than in a typical front-loading box furnace. This uniformity is critical for achieving repeatable and reliable results in research and quality control.

Total Atmospheric Control

The sealed nature of the tube is a defining advantage. It allows you to completely purge the ambient air and replace it with a high-purity gas. This is impossible in most other furnace types and is essential for working with air-sensitive materials.

Process Versatility and Adaptability

The combination of precise temperature and atmospheric control makes the tube furnace a flexible tool. It can be used for a vast range of processes, including annealing, sintering, purification, material synthesis, and crystal growth.

Understanding the Trade-offs and Considerations

While powerful, a tube furnace is not the right tool for every job. Understanding its limitations is key to using it effectively.

Sample Size and Throughput Limitations

The diameter of the furnace tube inherently limits the size and volume of the material you can process at one time. They are ideal for high-precision work on smaller samples, not for high-volume industrial production of large parts.

Material Compatibility is Critical

The choice of tube material is a crucial decision. Quartz is cost-effective and excellent for temperatures up to ~1200°C, but it can become brittle and may react with certain alkaline materials. Alumina can withstand much higher temperatures (1600°C or more) but is more expensive.

Thermal Shock and Ramp Rates

Ceramic furnace tubes can crack if heated or cooled too quickly. This phenomenon, known as thermal shock, requires users to program controlled temperature ramp rates. While this ensures safety and equipment longevity, it can extend the total process time.

Making the Right Choice for Your Application

Selecting the right thermal processing equipment depends entirely on your end goal.

- If your primary focus is material synthesis under a specific gas: A tube furnace is the ideal choice due to its superior atmospheric control.

- If your primary focus is achieving highly uniform heat treatment on small parts: The circumferential heating of a tube furnace provides better temperature consistency than a standard box furnace.

- If your primary focus is high-volume processing of large items: A different solution, such as a larger industrial box furnace or a conveyor furnace, will be more efficient.

Ultimately, a tube furnace empowers you to control the two most critical variables in thermal processing: precise temperature and a pure atmosphere.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Tube | Isolates sample and withstands high temperatures | Made from quartz (up to 1200°C) or alumina (up to 1600°C+) |

| Heating Element | Provides indirect, uniform heat | External placement ensures consistent temperature in hot zone |

| Temperature Control | Maintains precise temperature | Uses thermocouple and PID controller for accuracy and safety |

| Gas System | Controls atmosphere for processes | Allows flow of inert or reactive gases to prevent oxidation or aid synthesis |

Ready to enhance your lab's capabilities with a high temperature tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for material synthesis, annealing, and more. Contact us today to discuss how our furnaces can deliver superior temperature uniformity and atmospheric control for your research!

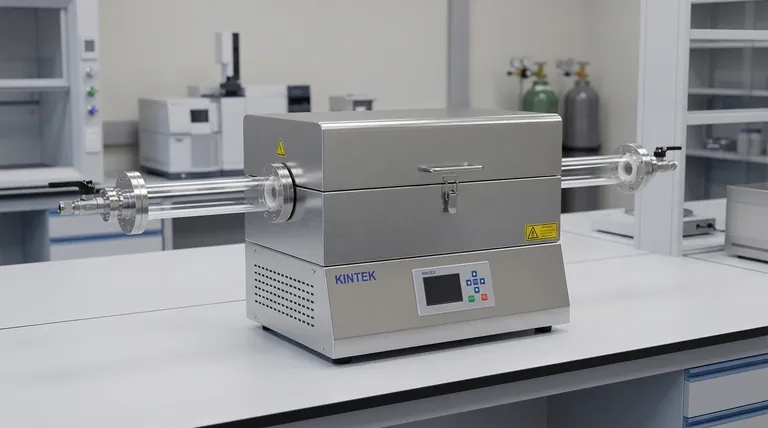

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing