In short, a quartz tube furnace is adapted for vacuum operations by sealing a high-purity quartz tube with specialized, airtight connections. These connections, typically at both ends of the tube, feature ground joint structures, piston valves, and links to a vacuum pump, all designed to create and maintain a controlled, low-pressure environment during high-temperature processing.

The key is not just attaching a vacuum pump. A true vacuum furnace is an integrated system where the sealing method, heating elements, insulation, and control system are all specifically chosen for their compatibility with a low-pressure, high-purity environment.

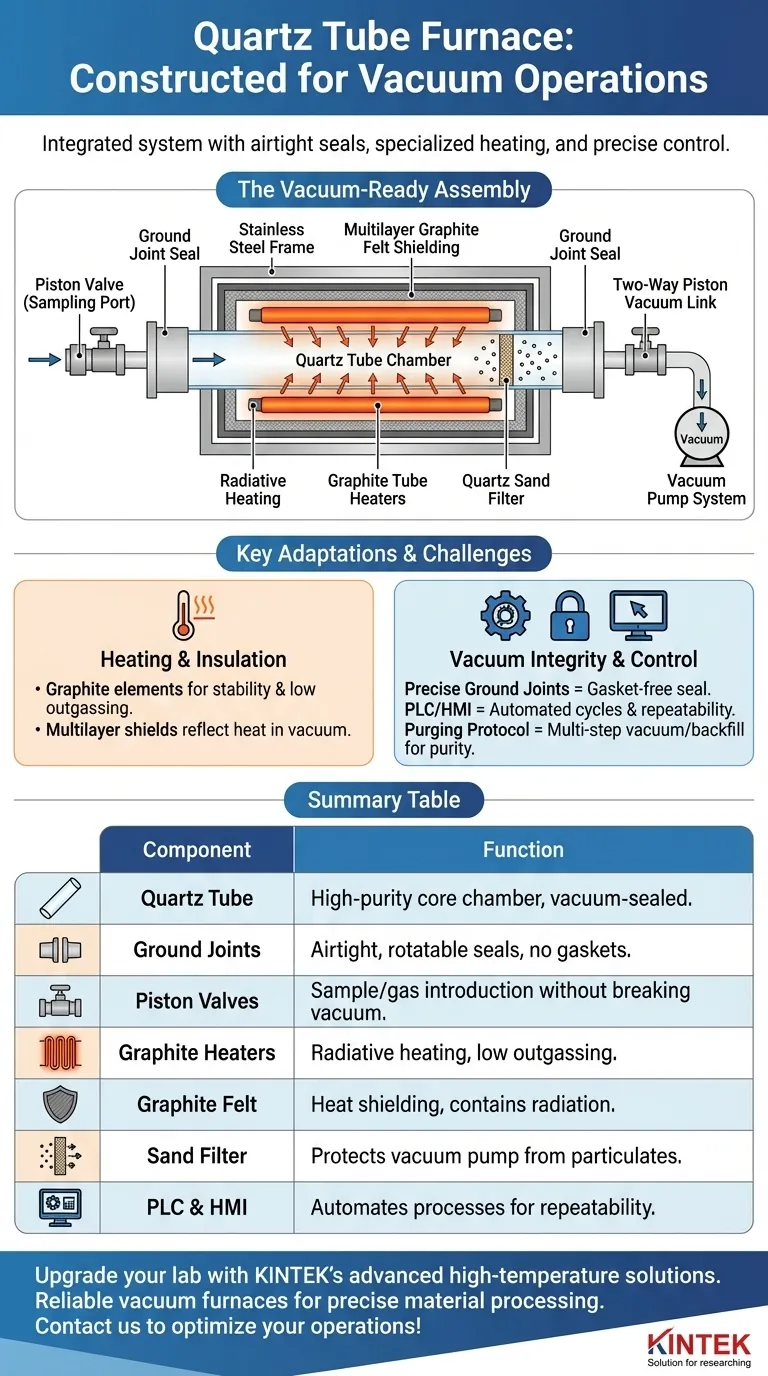

The Anatomy of a Vacuum-Ready Tube Furnace

To understand how these furnaces work, it's essential to look at the individual components and how they contribute to the vacuum-tight, high-temperature system.

The Quartz Tube and Sealing Assembly

The core of the furnace is the tube itself, which must be perfectly sealed from the outside atmosphere. This is achieved through a combination of components at each end.

At the front, a piston valve sampling port is common. This allows for introducing or removing small samples or gases without breaking the main vacuum seal.

At the rear, a two-way piston vacuum link connects the furnace tube to the vacuum pump system.

Ground Joint Connections

Both the front and rear ports typically use ground joint structures. These are precisely machined, smooth surfaces that fit together perfectly, creating a strong seal without the need for gaskets that could degrade at high temperatures or contaminate the process.

This design often allows the connections to be rotated, which simplifies the process of attaching and detaching vacuum lines and other apparatus.

Protecting the Vacuum System

To ensure the longevity of the expensive vacuum pump, a quartz sand filter is often installed inside the furnace tube, between the main chamber and the vacuum port.

This simple filter serves a critical function: it traps any particulate matter generated during the experiment, preventing it from being sucked into and damaging the vacuum pump.

Creating Heat in a Vacuum

Heating a chamber with no air presents a unique challenge, as convection is no longer a significant mode of heat transfer. The furnace's heating chamber must be designed specifically for radiative heating in a vacuum.

Heating Elements

The system often uses graphite tube heaters. Graphite is an excellent choice because it performs well at very high temperatures and is stable in a vacuum, meaning it won't release significant amounts of gas (outgas) that would contaminate the environment.

These heaters are known for being simple to install and maintain. Some systems may offer an all-metal heating structure as an alternative for specific applications where graphite is unsuitable.

Insulation and Heat Shielding

The heating elements are housed within a durable stainless steel frame.

To contain the intense heat, the chamber is lined with multilayer graphite felt heat shields. In a vacuum, these layers act like a high-tech thermos, reflecting thermal radiation back into the chamber and preventing the outer body of the furnace from overheating.

Understanding the Trade-offs and Operational Realities

Achieving a clean vacuum is not as simple as flipping a switch. The design and operation both have nuances that are critical to success.

The Purging Protocol

Simply pumping the air out once is not enough to achieve a pure atmosphere. Air and moisture molecules cling to the inner surfaces of the furnace tube.

The recommended procedure is to first pre-pump a vacuum and then backfill the tube with a high-purity inert gas. Repeating this vacuum/purge cycle several times effectively "washes" the residual atmospheric gases out of the system.

The Challenge of Outgassing

All materials, including the sample you are heating and the furnace components themselves, can release trapped gases when heated in a vacuum. This phenomenon, called outgassing, can degrade the quality of your vacuum and contaminate your experiment.

This is why furnace construction uses vacuum-compatible materials like graphite and high-purity quartz.

Process Control and Repeatability

Modern vacuum furnaces rely on sophisticated control systems to manage these complex processes. A PLC (Programmable Logic Controller) enables the automation of heating profiles, pumping cycles, and gas flow.

An intuitive HMI (Human-Machine Interface) allows operators to define and save process recipes, ensuring that experiments are highly repeatable and can be monitored or even controlled remotely.

Making the Right Choice for Your Application

Understanding the construction of a vacuum tube furnace helps you select a system and operate it effectively based on your scientific goals.

- If your primary focus is ultimate purity: Prioritize a furnace with high-quality ground joint seals and commit to a rigorous multi-step purging protocol before every run.

- If your primary focus is process repeatability: A system with integrated PLC and HMI control is essential for defining and executing identical process recipes every time.

- If your primary focus is system longevity: Look for features like integrated particulate filters to protect the vacuum pump and robust, easily maintained graphite heating elements.

Ultimately, a properly constructed vacuum tube furnace is more than a heater; it is a precisely engineered environment enabling advanced material processing.

Summary Table:

| Component | Function in Vacuum Operations |

|---|---|

| Quartz Tube | High-purity core chamber, sealed for vacuum integrity |

| Ground Joint Connections | Airtight seals without gaskets, rotatable for easy access |

| Piston Valves | Allow sample/gas introduction without breaking vacuum |

| Graphite Tube Heaters | Radiative heating, stable in vacuum with low outgassing |

| Multilayer Graphite Felt | Heat shielding to contain radiation and prevent overheating |

| Quartz Sand Filter | Protects vacuum pump by trapping particulates |

| PLC and HMI Control | Automates processes for repeatability and remote monitoring |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable vacuum tube furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing purity, repeatability, and longevity in material processing. Contact us today to discuss how we can optimize your vacuum operations!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents