In short, multi-zone tube furnaces are indispensable in materials science because they allow researchers to create and control precise temperature gradients along a single processing tube. This capability moves beyond simple uniform heating, enabling complex, multi-stage processes like material synthesis, deposition, and annealing to occur sequentially within a single experiment, dramatically improving precision and efficiency.

The core value of a multi-zone furnace isn't just heating; it's the ability to create a controlled, non-uniform temperature landscape. This unlocks advanced material fabrication techniques that are impossible to achieve with a standard, single-zone furnace.

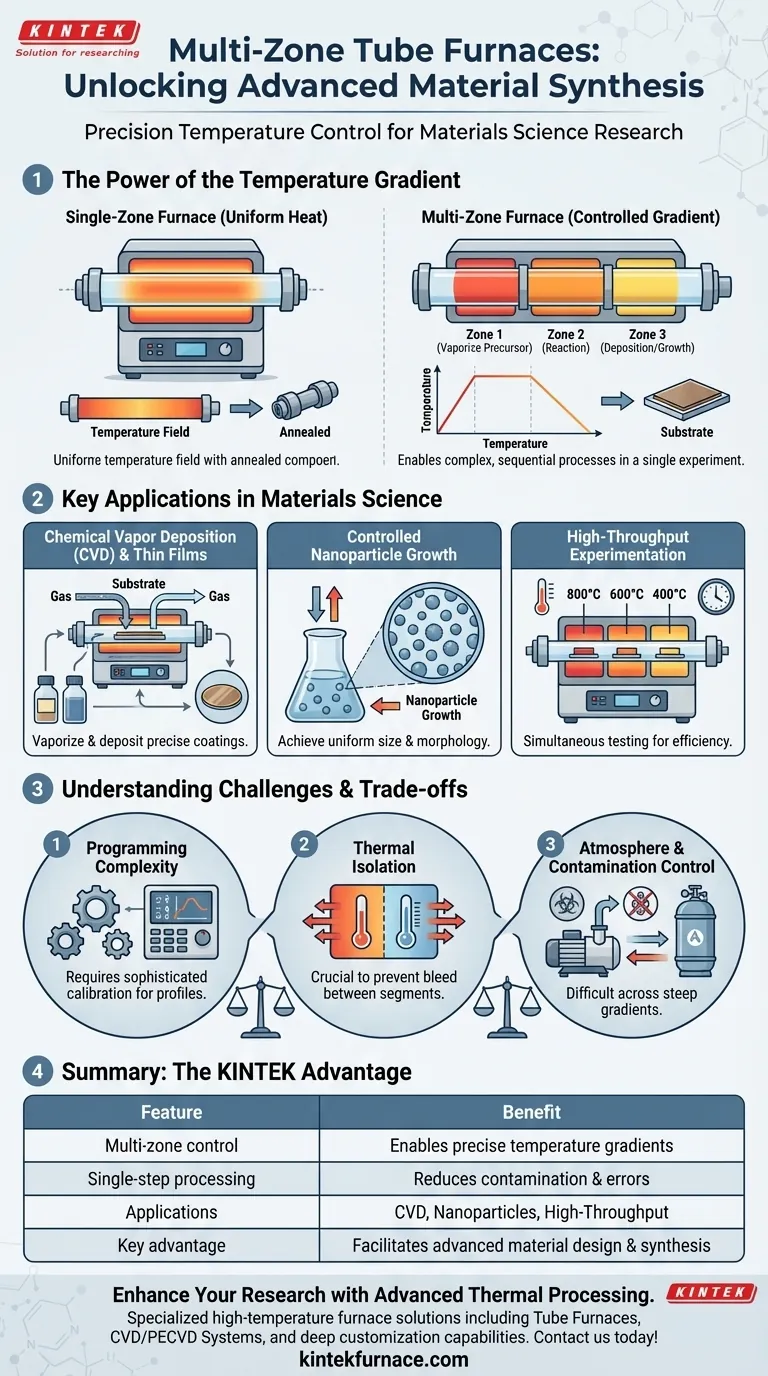

The Power of the Temperature Gradient

The defining feature of a multi-zone tube furnace is its ability to move beyond simple, uniform heat. This unlocks a new level of process control that is fundamental to modern materials research.

What is a Multi-Zone Furnace?

A standard tube furnace uses a single heating element to create a uniform hot zone. In contrast, a multi-zone furnace has two, three, or more independently controlled heating segments arranged along the length of the process tube.

Each segment acts as its own furnace, allowing a researcher to program a specific temperature for each section. This creates a precise temperature profile or gradient along the tube.

From Uniformity to Controlled Profiles

Single-zone furnaces are excellent for processes that require one stable temperature, like annealing a finished component. However, many advanced synthesis techniques require different temperatures at different stages.

A multi-zone furnace allows you to establish, for example, a very hot zone to vaporize a precursor material, an intermediate zone for gas-phase reactions, and a cooler zone for controlled deposition or crystal growth—all within one continuous process.

The Core Advantage: Process Control in a Single Step

This integrated control allows for complex processes like Chemical Vapor Deposition (CVD) to be performed efficiently. It eliminates the need to move samples between multiple furnaces set at different temperatures, which reduces the risk of contamination and experimental error.

Key Applications in Materials Science

The ability to engineer a temperature profile makes multi-zone furnaces essential for creating the next generation of advanced materials.

Advanced Material Synthesis

These furnaces are used to synthesize novel materials like nanomaterials, ceramics, and composites. The temperature gradient can be used to control reaction kinetics, leading to materials with specific, desired properties and morphologies.

Chemical Vapor Deposition (CVD) and Thin Films

CVD is a cornerstone of semiconductor and coatings industries. A multi-zone furnace is ideal for this, creating a hot zone to vaporize precursor chemicals and a cooler target zone where the vapor decomposes and deposits as a thin film on a substrate.

Controlled Nanoparticle Growth

The size, shape, and uniformity of nanoparticles are highly dependent on temperature. By using a precise gradient, researchers can manage the nucleation and growth phases of nanoparticle synthesis to achieve uniform size distributions and morphologies, which is critical for their performance.

High-Throughput Experimentation

A multi-zone furnace can also be used to increase experimental throughput. Researchers can place multiple small samples in different zones to test their thermal stability or reaction behavior at various temperatures simultaneously in a single run.

Understanding the Challenges and Trade-offs

While powerful, the precision of multi-zone furnaces comes with inherent complexities that users must manage.

Complexity in Programming

Controlling multiple zones requires more sophisticated programming and calibration. Achieving a desired temperature profile is more complex than simply setting a single temperature, as the zones inevitably influence each other.

True Thermal Isolation

A key challenge in furnace design is preventing thermal "bleed" between adjacent zones. Without effective insulation between segments, the sharpness of the temperature gradient is reduced, potentially impacting the precision of processes like CVD.

Atmosphere and Contamination Control

Maintaining a pure, controlled atmosphere (such as a vacuum or inert gas) across a steep temperature gradient can be difficult. Outgassing from hotter sections of the tube or furnace can contaminate processes occurring in cooler zones if not properly managed.

Making the Right Choice for Your Goal

Selecting the right thermal processing tool depends entirely on your experimental objective.

- If your primary focus is uniform heat treatment or annealing: A well-calibrated single-zone furnace is often sufficient, more cost-effective, and simpler to operate.

- If your primary focus is chemical vapor deposition (CVD) or gradient-based synthesis: A multi-zone furnace is non-negotiable for creating the required temperature profile.

- If your primary focus is high-throughput screening of materials: A multi-zone furnace provides an efficient platform for simultaneously testing samples at different, stable temperatures.

Mastering the control of temperature profiles is what allows researchers to move from simply analyzing materials to actively designing them at the atomic level.

Summary Table:

| Feature | Benefit |

|---|---|

| Multi-zone control | Enables precise temperature gradients for complex processes |

| Single-step processing | Reduces contamination and errors by eliminating sample transfers |

| Applications | CVD, nanoparticle growth, high-throughput experimentation |

| Key advantage | Facilitates advanced material design and synthesis in one setup |

Ready to enhance your materials science research with advanced thermal processing? KINTEK specializes in providing high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Tube Furnaces, CVD/PECVD Systems, and more, with strong deep customization capabilities to meet your specific experimental requirements. Contact us today to discuss how our multi-zone tube furnaces can drive precision and efficiency in your lab!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents