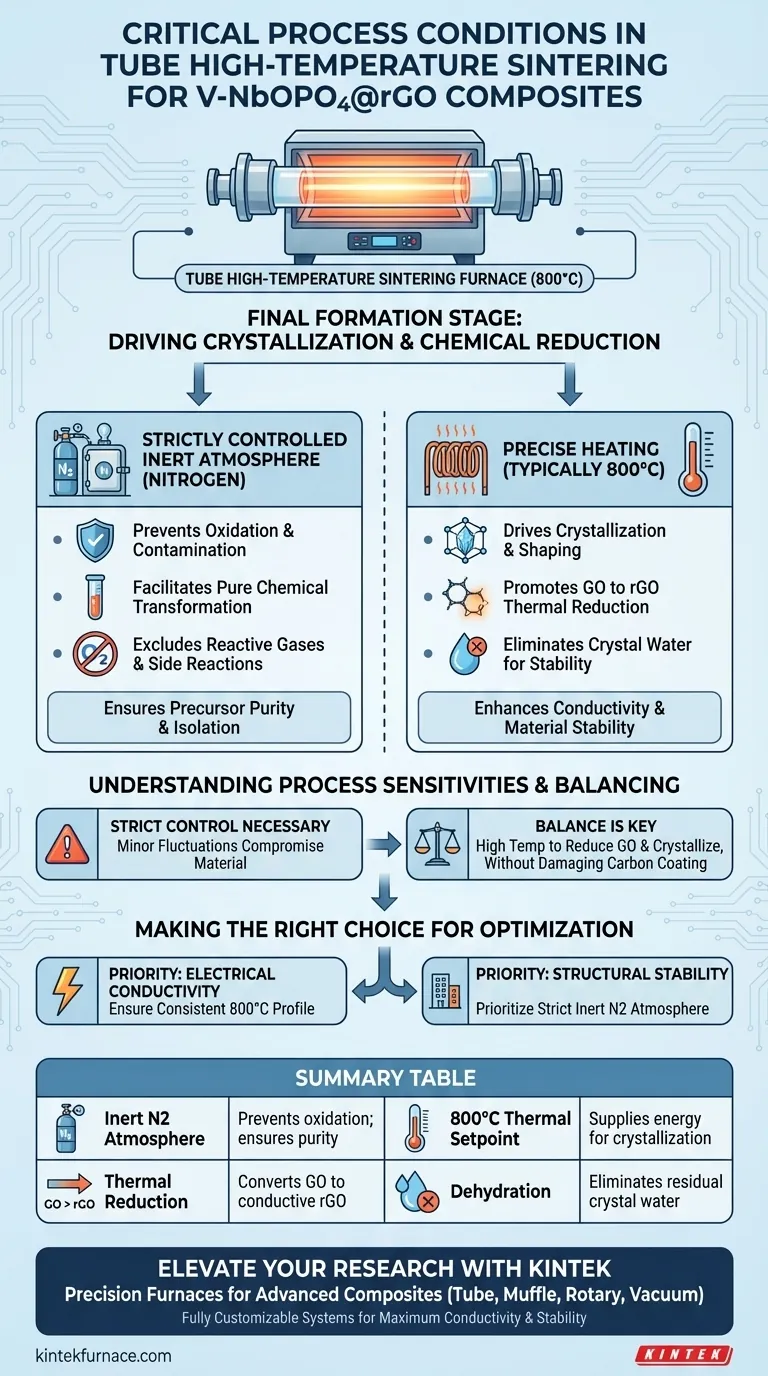

The tube high-temperature sintering furnace creates a critical processing environment defined by a strictly controlled inert nitrogen atmosphere and precise heating, typically at 800°C. These conditions are necessary to crystallize the precursor, thermally reduce graphene oxide (GO) into conductive reduced graphene oxide (rGO), and eliminate crystal water from the V-NbOPO4@rGO structure.

By maintaining a precise inert environment at high heat, the furnace simultaneously drives structural crystallization and chemical reduction. This dual action transforms raw precursors into a highly conductive, stable composite free of moisture, essential for advanced material performance.

The Role of the Inert Atmosphere

Strictly Controlled Nitrogen Environment

The furnace utilizes a nitrogen atmosphere to create an inert environment during the sintering process. This prevents external contaminants or oxygen from interfering with the chemical formation of the composite.

Facilitating Chemical Transformation

By excluding reactive gases, the nitrogen atmosphere allows the internal chemical changes to proceed without side reactions. This isolation is vital for the purity of the final V-NbOPO4@rGO composite.

Thermal Mechanisms at 800°C

Driving Crystallization and Shaping

At temperatures such as 800°C, the furnace supplies the energy required to organize the atomic structure of the precursor. This heat treatment enables the material to crystallize properly and take on its final, defined shape.

Enhancing Electrical Conductivity

The high-temperature environment promotes the thermal reduction of graphene oxide (GO). As the GO converts into reduced graphene oxide (rGO), the material's electrical conductivity increases significantly.

Stabilizing the Compound

The sintering process ensures the complete elimination of crystal water from the structure. Removing this moisture is essential for creating a stable, vanadium-doped niobium phosphate carbon-coated composite that will not degrade over time.

Understanding Process Sensitivities

The Necessity of Strict Control

The term "strictly controlled" indicates that deviations in the atmosphere or temperature profile can compromise the material. Even minor fluctuations can prevent the complete reduction of GO or leave residual moisture in the lattice.

Balancing Reduction and Structure

The process relies on achieving a balance where the temperature is high enough to reduce GO and crystallize the phosphate without damaging the carbon coating. The 800°C setpoint is a specific parameter selected to optimize this trade-off.

Making the Right Choice for Your Goal

To optimize the synthesis of V-NbOPO4@rGO composites, consider your specific performance requirements:

- If your primary focus is electrical conductivity: Ensure the furnace maintains a consistent 800°C temperature profile to maximize the thermal reduction of GO into rGO.

- If your primary focus is structural stability: Prioritize the strict control of the inert nitrogen atmosphere to facilitate pure crystallization and the complete removal of crystal water.

Precise control over both atmosphere and temperature is the only way to ensure a stable, conductive, and high-performance final composite.

Summary Table:

| Process Parameter | Role in V-NbOPO4@rGO Formation |

|---|---|

| Inert Nitrogen Atmosphere | Prevents oxidation; ensures precursor purity and chemical isolation |

| 800°C Thermal Setpoint | Supplies energy for crystallization and atomic structural organization |

| Thermal Reduction | Converts Graphene Oxide (GO) to conductive rGO for better electrical performance |

| Dehydration | Eliminates residual crystal water to ensure long-term compound stability |

Elevate Your Material Research with KINTEK

Precision is non-negotiable when synthesizing advanced composites like V-NbOPO4@rGO. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Tube, Muffle, Rotary, and Vacuum furnaces designed to meet the strictest process sensitivities.

Whether you require precise 800°C thermal profiles or strictly controlled inert environments, our systems are fully customizable to your unique lab requirements. Achieve maximum conductivity and structural stability in your materials today.

Contact KINTEK for a Custom Solution

Visual Guide

References

- Zhongteng Chen, Zhipeng Sun. Tuning the Electronic Structure of Niobium Oxyphosphate/Reduced Graphene Oxide Composites by Vanadium‐Doping for High‐Performance Na<sup>+</sup> Storage Application. DOI: 10.1002/cnl2.70010

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are some common applications of tube furnaces in laboratories? Unlock Precision in Material Processing

- What are the primary applications of tubular furnaces? Precision Heat Treatment for Research and Industry

- How does an atmosphere tube furnace achieve precise temperature control? Master Temperature Stability for Your Lab

- How does the heat treatment temperature in a tube furnace influence RPW electrodes? Optimize Carbonization Performance

- How are tube furnaces utilized in environmental testing? Key Applications for Analysis and Remediation

- What are the advantages of using a vacuum tube furnace for biomass pyrolysis? Optimize Electrocatalyst Performance

- What are the pros and cons of vertical tube furnaces? Precision vs. Capacity for Your Lab

- What is the purpose of using a high-temperature tube furnace with a steam generator for LOCA simulation?