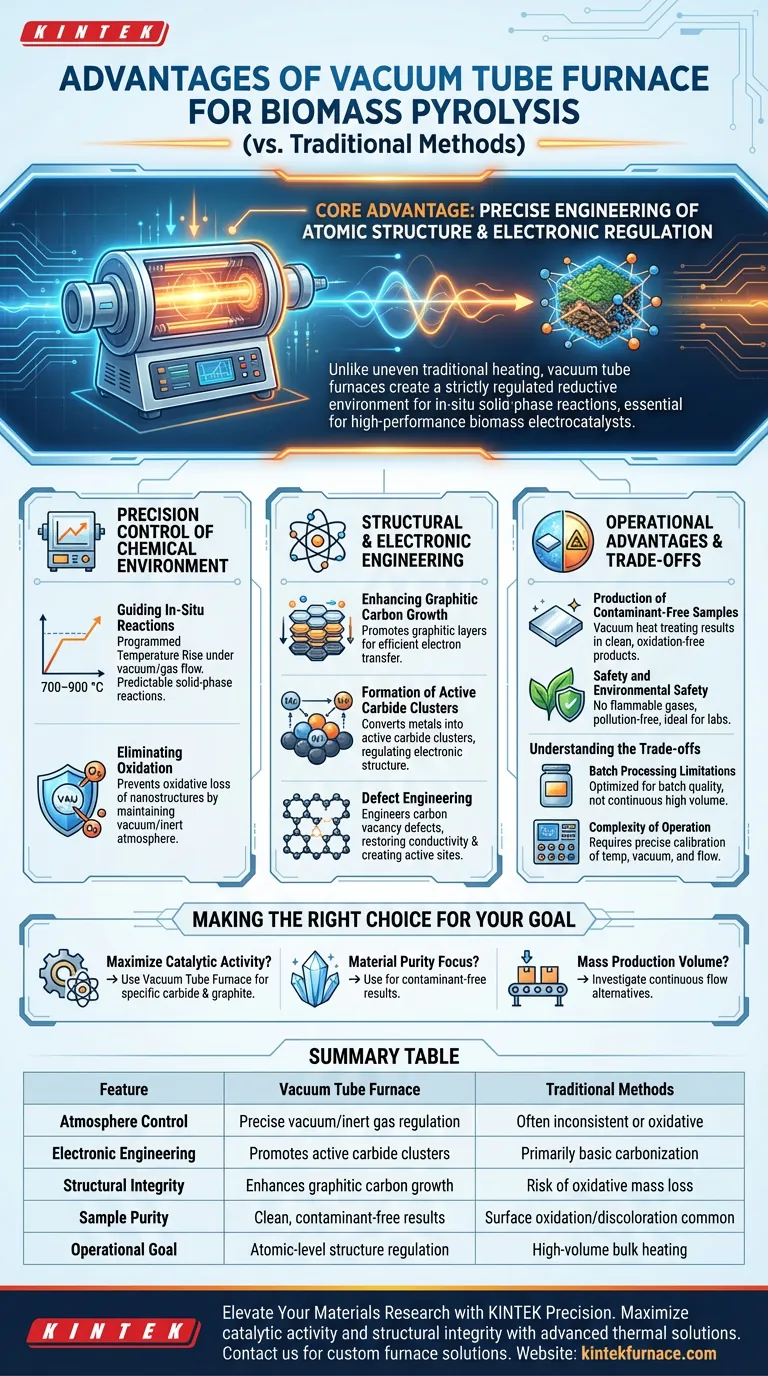

The primary advantage of using a vacuum tube furnace is its ability to precisely engineer the atomic structure of the electrocatalyst. Unlike traditional heating methods, which may suffer from uneven atmosphere control, a vacuum tube furnace creates a strictly regulated reductive environment. This allows you to direct in-situ solid-phase reactions between carbon sources and metal ions, a process essential for high-performance biomass applications.

The core value of this technology is not just heat, but electronic structure regulation. While standard furnaces simply carbonize material, a vacuum tube furnace enables the specific conversion of metals into active carbide clusters and promotes graphitic carbon growth, which are difficult to achieve with conventional methods.

Precision Control of the Chemical Environment

Guiding In-Situ Reactions

Traditional heating often lacks the atmospheric precision required for complex synthesis. A vacuum tube furnace allows for a programmed temperature rise (typically 700–900 °C) under a specific vacuum or gas flow. This controlled environment ensures that carbon sources and metal ions react predictably in the solid phase.

Eliminating Oxidation

Oxygen is the enemy of precise reductive synthesis. By maintaining a vacuum or inert atmosphere, this equipment prevents the oxidative loss of carbon nanotubes and other delicate nanostructures. This ensures the material retains its intended mass and structural integrity rather than burning off into the atmosphere.

Structural and Electronic Engineering

Enhancing Graphitic Carbon Growth

For an electrocatalyst to function, it needs excellent electrical conductivity. The specific conditions provided by a vacuum tube furnace promote the growth of graphitic carbon layers. This graphitization is critical for ensuring efficient electron transfer during catalytic processes.

Formation of Active Carbide Clusters

The primary reference highlights a distinct advantage: the conversion of metal components into specific carbide clusters. This process effectively regulates the material's electronic structure. Traditional thermal methods often fail to achieve this level of chemical specificity, leading to less active metal oxides rather than the desired carbides.

Defect Engineering

Beyond basic carbonization, these furnaces allow for the engineering of carbon vacancy defects. By removing specific oxygen-containing functional groups, the process restores electrical conductivity and creates active sites that improve adsorption kinetics and sensitivity.

Operational Advantages

Production of Contaminant-Free Samples

Vacuum heat treating results in clean, shiny products free from surface oxidation or discoloration. Because the process occurs in an oxygen-free, contaminant-free environment, post-processing cleaning is often eliminated, adding value to the final component.

Safety and Environmental Safety

Compared to methods involving open flames or hazardous gas byproducts, vacuum tube furnaces are notably safer. They generally involve no flammable gases and are pollution-free, making them ideal for laboratory environments where health hazards must be minimized.

Understanding the Trade-offs

Batch Processing Limitations

While excellent for precision, vacuum tube furnaces are typically batch-processing tools. They may not match the continuous high-volume throughput of industrial rotary kilns or conveyor furnaces, potentially acting as a bottleneck in large-scale manufacturing.

Complexity of Operation

Achieving the precise "programmed temperature rise" and maintaining specific vacuum levels requires more complex calibration than a standard muffle furnace. The operator must carefully balance gas flow, pressure, and ramp rates to avoid thermal shock or incomplete reactions.

Making the Right Choice for Your Goal

To determine if a vacuum tube furnace is the right tool for your specific biomass pyrolysis project, consider your end goals:

- If your primary focus is maximizing catalytic activity: Use a vacuum tube furnace to ensure the formation of specific metal carbide clusters and graphitic layers that define high performance.

- If your primary focus is material purity: Choose this method to eliminate oxygen-induced defects and surface contaminants that could interfere with electrochemical readings.

- If your primary focus is mass production volume: You may need to investigate if the precise atmosphere control can be replicated in a continuous flow furnace, as the tube furnace is optimized for batch quality over quantity.

Ultimately, the vacuum tube furnace is the superior choice when the definition of the material's electronic structure is more critical than simple carbonization speed.

Summary Table:

| Feature | Vacuum Tube Furnace | Traditional Methods |

|---|---|---|

| Atmosphere Control | Precise vacuum/inert gas regulation | Often inconsistent or oxidative |

| Electronic Engineering | Promotes active carbide clusters | Primarily basic carbonization |

| Structural Integrity | Enhances graphitic carbon growth | Risk of oxidative mass loss |

| Sample Purity | Clean, contaminant-free results | Surface oxidation/discoloration common |

| Operational Goal | Atomic-level structure regulation | High-volume bulk heating |

Elevate Your Materials Research with KINTEK Precision

Maximize the catalytic activity and structural integrity of your biomass-based materials with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of modern laboratory environments.

Whether you need to engineer specific carbide clusters or optimize defect density, our customizable furnaces ensure the precise temperature and atmospheric control required for your unique research goals.

Ready to achieve superior heat treatment results? Contact us today to find your custom furnace solution!

Visual Guide

References

- Chengyu Zhang, Zhisheng Yu. Electronic configuration regulation of single-atomic Mn sites mediated by Mo/Mn clusters for an efficient hydrogen evolution reaction. DOI: 10.1039/d3sc06053e

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a high-temperature tube furnace contribute to the solution treatment of titanium-aluminum alloys?

- What is the role of high-temperature tube furnaces in the post-processing of graphite oxide nanostructures?

- What are the handling and placement precautions for a vacuum tube furnace? Ensure Safe and Efficient Operation

- What is the significance of the temperature control program in a tube furnace for KBaBi crystals? Precise Growth Expert

- Why is it necessary to use a tube furnace for air oxidation of the 3D copper framework? Master Lithiophilic Interfaces

- What are the two primary types of tube furnaces and their main features? Compare Split vs. Solid Designs

- What advanced control features do modern tube furnaces have? Precision Temperature, Atmosphere, and Data Control

- How does a high-temperature tube furnace contribute to the atmosphere-controlled sintering of Mn-Zn ferrites?