Proper handling and placement of a vacuum tube furnace are foundational to its safe and effective operation. To prevent damage and ensure safety, you must move the furnace without severe vibration, never lift it by its door, and place it in a stable, well-ventilated area free from flammable, explosive, or wet conditions.

A vacuum tube furnace is not just a heater; it is a precision instrument operating under extreme conditions of temperature and pressure. The precautions for its placement and handling are designed to protect its most vulnerable components—the vacuum seals, heating elements, and furnace tube—which are critical for both safety and experimental integrity.

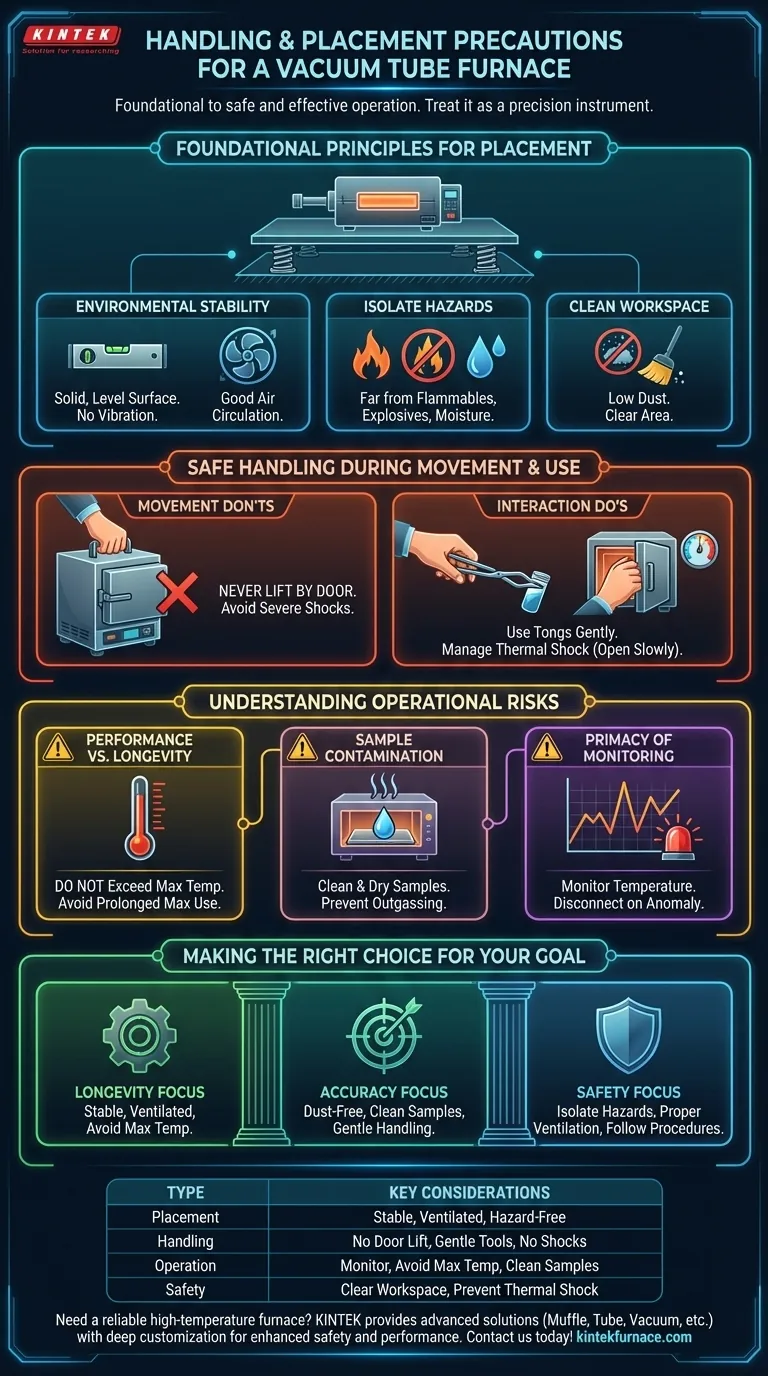

Foundational Principles for Placement

Where you install the furnace has a direct impact on its performance, longevity, and safety. The environment must be controlled and stable.

Environmental Stability is Non-Negotiable

The equipment must be placed on a solid, level surface with no vibration. Vibration can damage the delicate heating elements or disrupt sample integrity within the tube.

Good air circulation around the furnace is also essential. This helps dissipate heat from the furnace casing and control electronics, preventing overheating and extending the life of the components.

Isolate from Hazardous Materials

Position the furnace far away from any flammable gases, explosive materials, or sources of moisture. The high temperatures present an obvious ignition risk, and any water can cause electrical short-circuits or catastrophic failure of the hot furnace tube.

Maintain a Clean and Clear Workspace

The area should have low dust levels. Dust can be drawn into the electronics, act as an insulator causing components to overheat, or contaminate your experiments when the furnace is opened.

A clear, uncluttered workspace around the furnace is a basic safety requirement, ensuring operators can move freely and respond quickly in an emergency.

Safe Handling During Movement and Use

Physical interaction with the furnace, whether moving it or using it for an experiment, requires a deliberate and careful approach.

Protecting Structural Integrity

Under no circumstances should you lift or move the furnace by its door. The door, its hinges, and its sealing mechanism are precision components designed to maintain vacuum integrity. Using them as a lifting point will cause misalignment or damage, leading to vacuum leaks.

When transporting the unit, avoid any severe shocks or resonance that could crack the internal ceramic insulation or the furnace tube itself.

Interacting with the Furnace Chamber

When placing or removing samples, use crucible tongs gently. The furnace tube, often made of quartz or alumina, is brittle and can easily be chipped or cracked by careless impact.

A damaged furnace tube compromises the vacuum, can ruin an experiment, and is costly to replace.

Managing Thermal Shock

After a heating cycle is complete, do not open the door fully right away. Open it slightly first to allow temperature to equalize more slowly.

This practice helps prevent thermal shock to both the hot sample and the furnace tube, reducing the risk of them cracking. It also prevents a sudden rush of air from disturbing powdered samples.

Understanding the Operational Risks

Beyond physical placement, day-to-day operation carries its own set of precautions tied directly to the nature of the equipment.

Performance vs. Longevity

Do not exceed the furnace's maximum rated temperature. Furthermore, avoid operating the furnace at its absolute maximum temperature for prolonged periods.

Pushing the equipment to its thermal limit significantly shortens the lifespan of critical components like heating elements and thermocouples, leading to more frequent and costly maintenance.

The Hidden Danger of Sample Contamination

Always ensure samples are properly cleaned and dried before being placed in the furnace. Moisture, oils, or other contaminants can outgas under vacuum at high temperatures.

This outgassing can ruin the desired vacuum level, contaminate the experiment, and even damage the vacuum pump system.

The Primacy of Monitoring

During operation, an operator must monitor the temperature display for any abnormal behavior. If the temperature fluctuates wildly or rises uncontrollably, immediately disconnect the power.

Such anomalies indicate a failure in the control system or thermocouple. Continuing to operate the furnace in this state is a significant safety hazard and requires professional diagnosis and repair.

Making the Right Choice for Your Goal

Your primary objective dictates which precautions are most critical.

- If your primary focus is equipment longevity: Avoid running at maximum rated temperature and ensure the furnace is placed in a stable, well-ventilated, vibration-free environment.

- If your primary focus is experimental accuracy: Prioritize a dust-free environment, use clean and dry samples, and handle materials gently to protect the integrity of the vacuum system.

- If your primary focus is operator safety: Strictly adhere to placement rules regarding hazardous materials, ensure proper ventilation, and always follow correct procedures for handling hot samples.

By treating the furnace as the precision instrument it is, you ensure its reliability, safety, and performance for years to come.

Summary Table:

| Precaution Type | Key Considerations |

|---|---|

| Placement | Stable surface, good ventilation, away from hazards like flammables and moisture |

| Handling | Avoid lifting by door, prevent vibration, use gentle tools for samples |

| Operation | Monitor temperature, avoid max temperature overuse, ensure clean samples |

| Safety | Maintain clear workspace, prevent thermal shock, isolate from risks |

Need a reliable high-temperature furnace tailored to your lab's needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for enhanced safety and performance. Contact us today to discuss how our furnaces can benefit your research and operations!

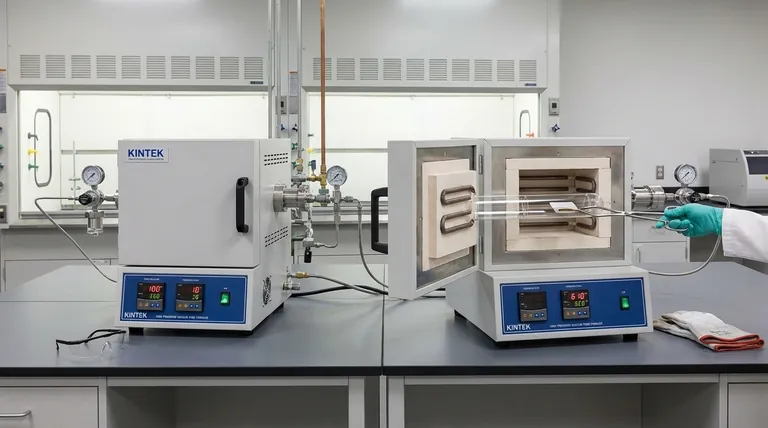

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What role do tube furnaces play in semiconductor and battery production? Unlock Precision in High-Temp Processing

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions