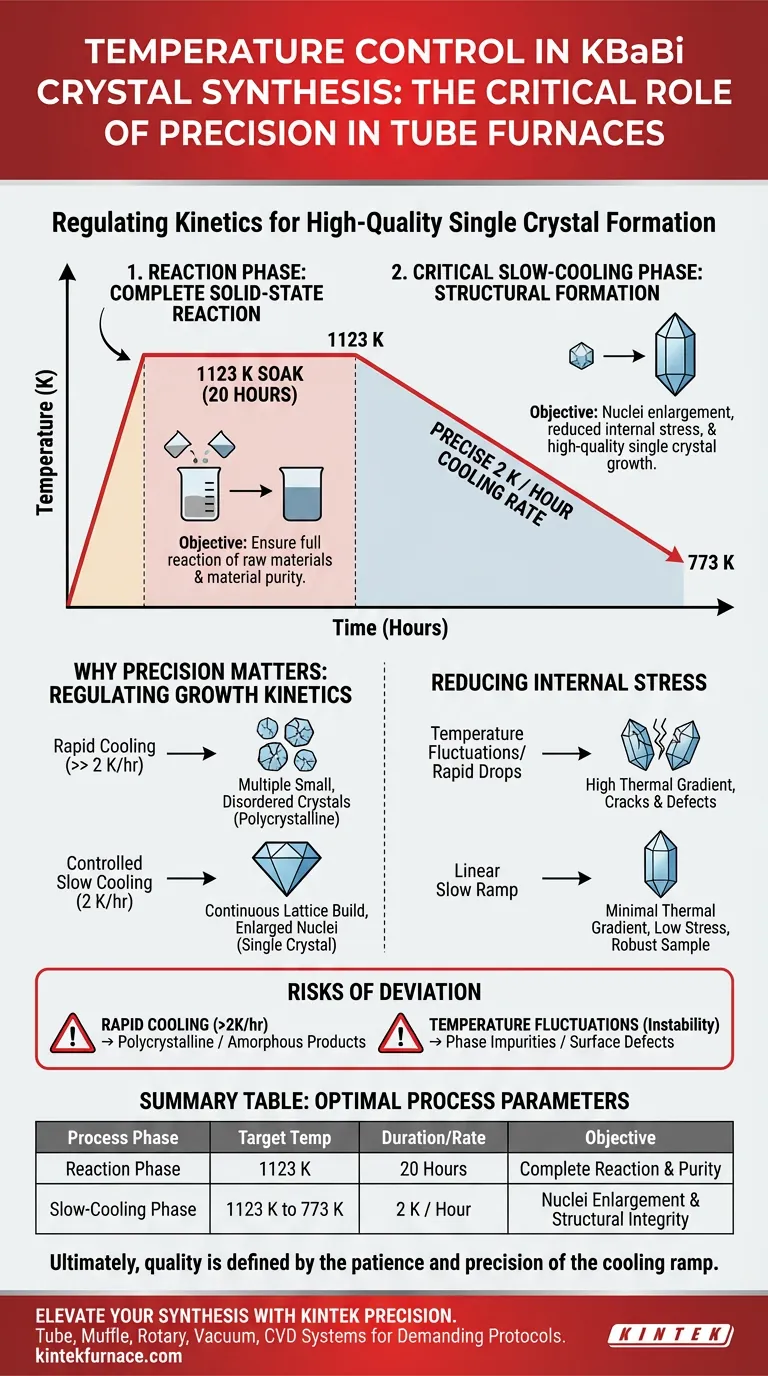

The significance of the temperature control program lies in its ability to strictly regulate the kinetics of solid-state reactions and crystal nucleation. For KBaBi crystals specifically, this requires a dual-phase thermal profile: a sustained high-temperature soak to ensure reaction completeness, followed by a meticulously controlled slow-cooling phase to drive high-quality structural formation.

The success of KBaBi preparation hinges on a specific cooling rate of 2 K per hour. This gradual reduction in temperature is the primary mechanism that reduces internal stress and allows crystal nuclei to enlarge, ensuring the final product is a high-quality single crystal rather than a flawed or polycrystalline sample.

The Components of the Thermal Profile

Establishing the Reaction Phase

To initiate the formation of KBaBi, the furnace must maintain a stable, high-temperature environment.

The program first elevates the sample to 1123 K.

It holds this temperature for a duration of 20 hours. This "soaking" period is essential to facilitate the necessary solid-state reactions, ensuring the raw materials have fully reacted before crystallization begins.

The Critical Slow-Cooling Phase

Once the reaction phase is complete, the program shifts focus to crystal growth.

The furnace executes a controlled cooling ramp at a rate of 2 K per hour.

This slow descent continues until the temperature reaches 773 K. This specific rate is not arbitrary; it is the governing variable that dictates the physical quality of the resulting crystal.

Why Precision Control Dictates Quality

Regulating Growth Kinetics

The primary function of the temperature program during the cooling phase is to manage crystal growth kinetics.

Rapid cooling would force the material to solidify too quickly, likely resulting in multiple small, disordered crystals.

By limiting cooling to 2 K per hour, the program promotes the enlargement of KBaBi crystal nuclei. This allows the crystal lattice to build continuously and strictly, favoring the growth of large, single crystals.

Reducing Internal Stress

Temperature fluctuations or rapid drops in thermal energy introduce physical stress into a crystal lattice.

The programmed slow cooling minimizes the thermal gradient across the sample.

This reduction in thermal shock significantly reduces internal stress. A lower stress environment is vital for preventing cracks and structural defects, resulting in a physically robust sample.

Understanding the Risks of Deviation

While the outlined program is optimal for KBaBi, understanding the consequences of deviation highlights its importance.

The Risk of Rapid Cooling

If the cooling rate exceeds 2 K per hour, the system exits the optimal window for single-crystal growth.

This often leads to the formation of polycrystalline materials or amorphous products, rather than the desired single-crystal structure.

The Risk of Temperature Fluctuations

Precision is as important as the rate itself.

Any instability in holding the temperature (during the 1123 K soak) or strict linearity (during the cooling) can interrupt ionic migration.

This interruption can cause phase impurities or surface defects, compromising the integrity of the KBaBi sample.

Making the Right Choice for Your Goal

To ensure successful synthesis, you must align your furnace programming with your specific output requirements.

- If your primary focus is material purity: Ensure the 20-hour soak at 1123 K is uninterrupted to guarantee complete solid-state reaction of raw materials.

- If your primary focus is crystal size and structural integrity: Strictly adhere to the 2 K/hour cooling rate to minimize stress and maximize nuclei enlargement.

Ultimately, the quality of a KBaBi crystal is defined less by the maximum temperature reached and more by the patience and precision of the cooling ramp that follows.

Summary Table:

| Process Phase | Target Temperature | Duration/Rate | Objective |

|---|---|---|---|

| Reaction Phase | 1123 K | 20 Hours | Complete solid-state reaction & material purity |

| Slow-Cooling Phase | 1123 K to 773 K | 2 K / Hour | Nuclei enlargement & high-quality structural formation |

| Critical Factor | Linear Ramp | Precise Control | Reducing internal stress & preventing polycrystalline defects |

Elevate Your Crystal Synthesis with KINTEK Precision

Successful KBaBi preparation demands uncompromising thermal accuracy and linear cooling rates. At KINTEK, we understand that your research depends on the stability of your thermal profile.

Backed by expert R&D and manufacturing, KINTEK offers Tube, Muffle, Rotary, Vacuum, and CVD systems designed to handle the most demanding crystal growth protocols. Our lab high-temp furnaces provide the precise temperature control needed to maintain 2 K/hour ramps, ensuring high-purity single crystals every time.

Ready to achieve superior structural integrity? Contact our specialists today to customize a furnace for your unique needs.

Visual Guide

References

- Investigation of a Ternary Zintl Phase KBaBi: Synthesis, Crystal Structure, and Preliminary Transport Properties. DOI: 10.1002/zaac.202500064

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What makes tubular furnaces versatile? Unlock Precision in Material Processing

- What are the key application features of a fluidized bed vertical tube furnace? Boost Efficiency and Uniformity

- Why is it necessary to precisely control the oxygen flow rate in a tube furnace? Optimize Li-Deficient Composites

- Why is precise atmosphere control in a tube furnace critical for Ga2O3 annealing? Optimize Thin Film Defect Engineering

- How does a vertical tube furnace ensure effective hydrogen reduction reactions? Optimize Rare Earth Tailing Processing

- How does the heating mechanism differ between vertical and horizontal tube furnaces? Optimize Your Lab's Thermal Processing

- How does a horizontal tube furnace facilitate the single-step annealing of BZSM nanophosphors? Expert Thermal Control

- What are the general advantages of tube furnace cracking? Unlock High-Yield Olefin Production with Reliable Efficiency