In short, a tubular furnace's versatility stems from its unique ability to provide exceptional control over a material's processing environment. This is achieved through a combination of precise temperature management, the ability to manipulate the atmosphere within the tube, and a design that adapts to a wide array of scientific and industrial processes, from heat treatment to advanced material synthesis.

The core reason for a tubular furnace's adaptability is not just its wide range of applications, but its fundamental design. The enclosed tube acts as a discrete, highly controllable micro-environment, making it the superior choice for any process where precision and atmospheric purity are critical.

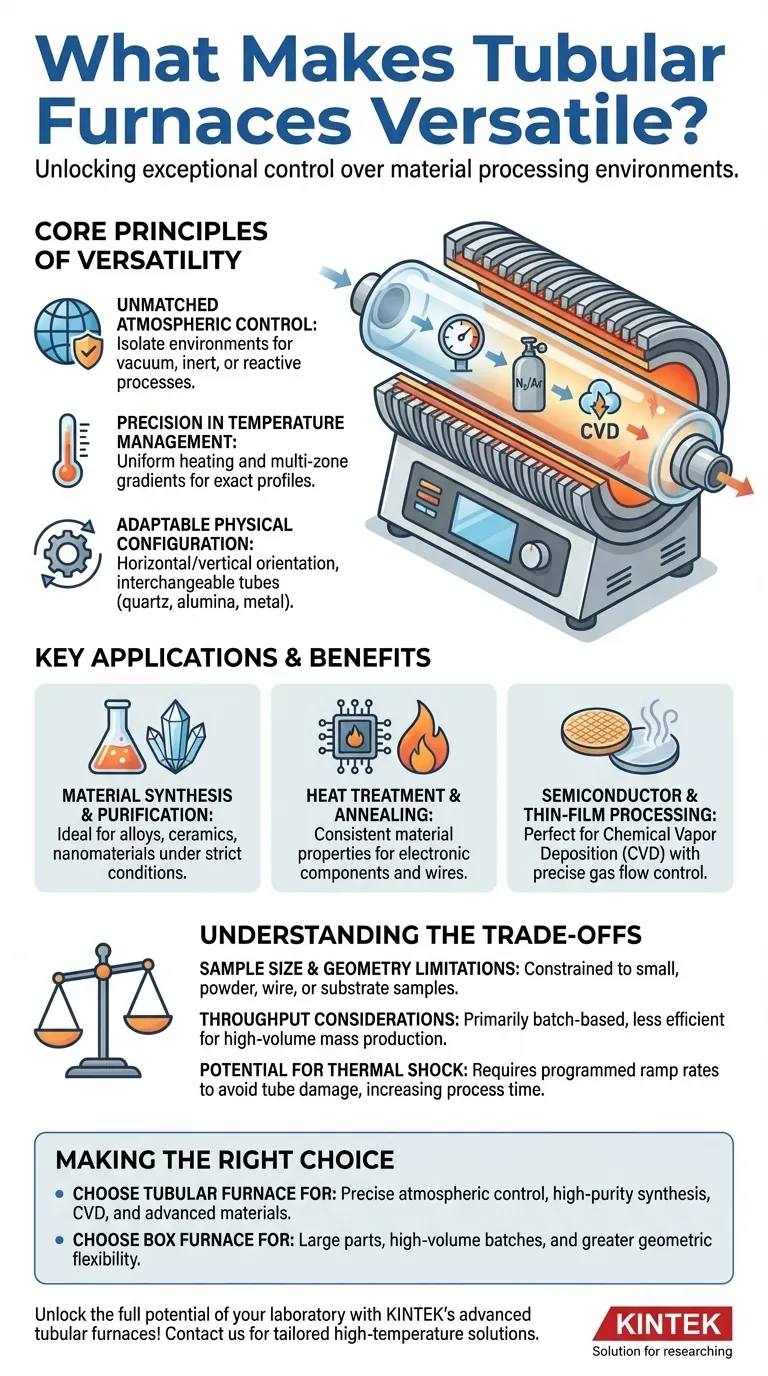

The Core Principles of Tubular Furnace Versatility

A tubular furnace is more than just a heating element wrapped around a cylinder. Its design is a deliberate choice that enables specific capabilities, making it a cornerstone tool in research and specialized manufacturing.

Unmatched Atmospheric Control

The single most important feature is the ability to isolate the internal environment. The tube can be sealed at both ends, allowing users to introduce specific conditions.

This enables processes under vacuum, in an inert gas atmosphere (like argon or nitrogen) to prevent oxidation, or with reactive gases for processes like chemical vapor deposition (CVD).

Precision in Temperature Management

Tubular furnaces offer exceptional temperature uniformity along the length of the heated zone. Many models are available with multiple heating zones.

These multi-zone configurations allow for the creation of precise temperature gradients, which are essential for crystal growth, material purification, and other advanced thermal processes.

Adaptable Physical Configuration

The furnace's orientation can be tailored to the process. Horizontal furnaces are common for batch processing and CVD, while vertical furnaces are ideal for crystal growth or processes where gravity assists in material handling.

Furthermore, the process tube itself is interchangeable. Users can swap between quartz tubes for purity and optical transparency, alumina for very high temperatures, or metal alloys for specific reactive processes.

Suitability for a Wide Range of Sample Types

While not ideal for large, bulky items, the tubular design is perfect for processing powders, wires, small components, and substrates.

Its geometry is perfectly suited for processes involving gas flow, where a gas must pass directly over the surface of a sample in a controlled and uniform manner.

Where This Versatility Shines: Key Applications

The combination of these features makes tubular furnaces indispensable across numerous fields. The tool is chosen when the quality of the thermal process is more important than the sheer volume of material.

Material Synthesis and Purification

Creating new alloys, ceramics, or nanomaterials often requires strict avoidance of oxygen and precise temperature profiles. The tubular furnace provides the exact environment needed.

Heat Treatment and Annealing

Processes like annealing metal wires to improve ductility or heat-treating small electronic components demand precise, repeatable temperature cycles. The control offered by a tubular furnace ensures consistent material properties.

Semiconductor and Thin-Film Processing

Applications like Chemical Vapor Deposition (CVD) are a perfect match for tubular furnaces. A precursor gas is flowed through the hot tube, where it decomposes and deposits a thin film onto a substrate, a process that requires absolute control over temperature and gas flow.

Understanding the Trade-offs

No tool is perfect for every job. Understanding the limitations of a tubular furnace is key to making an informed decision.

Sample Size and Geometry Limitations

The primary drawback is the constrained sample volume. Tubular furnaces are not suitable for processing large, bulky, or irregularly shaped objects. A box furnace is a much better choice for these applications.

Throughput Considerations

Most tubular furnace processes are batch-based, meaning one sample or set of samples is processed at a time. For high-volume mass production, a continuous belt or large-capacity box furnace would be more efficient.

Potential for Thermal Shock

The ceramic and quartz tubes used in these furnaces can be susceptible to cracking if heated or cooled too quickly. Operators must adhere to programmed ramp rates, which can increase overall process time compared to a robust metal-lined box furnace.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the requirements of your specific process.

- If your primary focus is precise atmospheric control: The sealed environment of a tubular furnace is the definitive choice for working under vacuum, inert gas, or with reactive gases.

- If your primary focus is high-purity synthesis or CVD: A tubular furnace provides the isolated, clean, and highly controlled environment essential for creating advanced materials and thin films.

- If your primary focus is heat-treating large parts or high-volume batches: A box furnace offers the superior capacity, geometric flexibility, and throughput needed for these tasks.

Ultimately, understanding that the tubular furnace is a tool for precision and control empowers you to select it for the sophisticated applications where it truly excels.

Summary Table:

| Feature | Benefit |

|---|---|

| Atmospheric Control | Enables vacuum, inert gas, or reactive gas environments for purity and safety. |

| Temperature Precision | Offers uniform heating and multi-zone gradients for consistent results. |

| Configurable Design | Supports horizontal/vertical orientation and interchangeable tubes for flexibility. |

| Wide Application Range | Ideal for material synthesis, heat treatment, and semiconductor processes. |

Unlock the full potential of your laboratory with KINTEK's advanced tubular furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions tailored to your needs. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your material processing with reliable, precise, and versatile furnace technology!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis