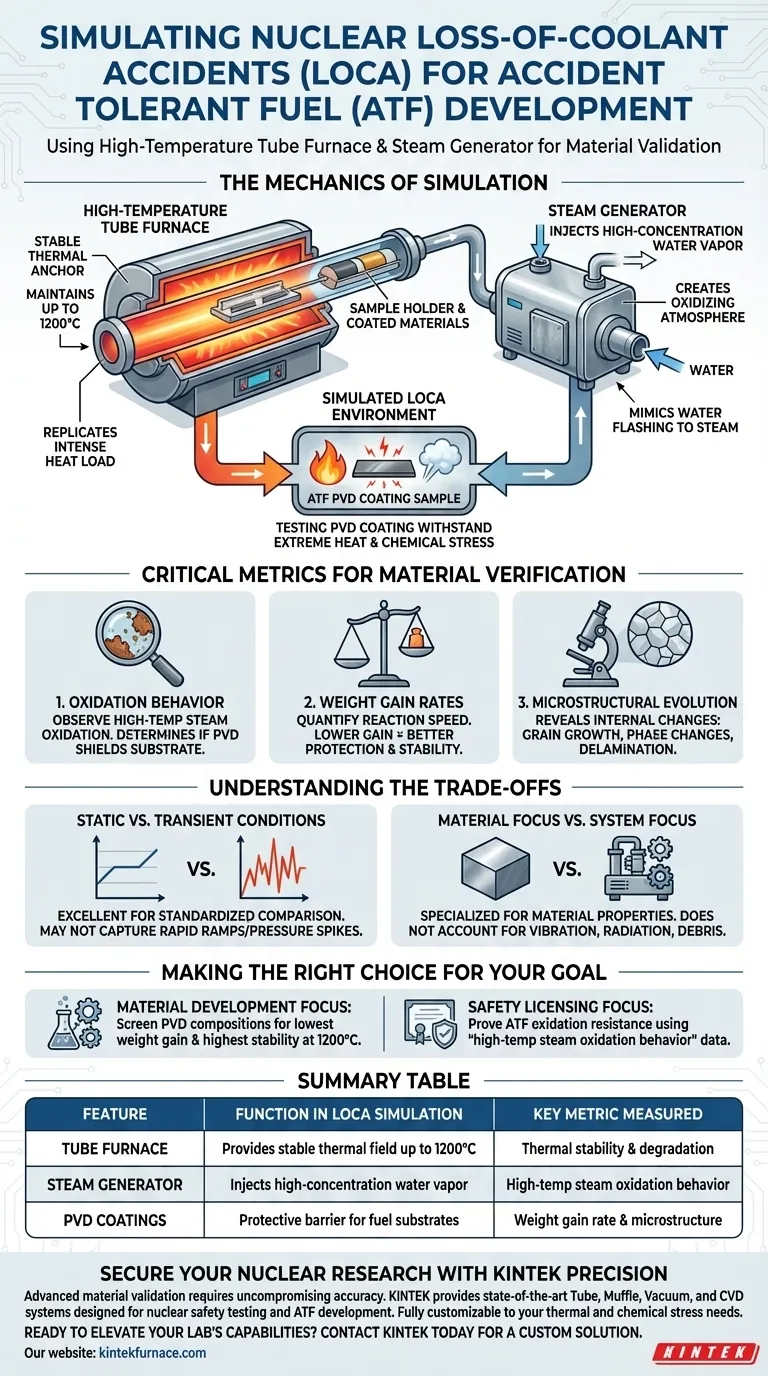

The primary purpose of using a high-temperature tube furnace combined with a steam generator is to engineer a controlled environment that rigorously simulates a Loss-of-Coolant Accident (LOCA) within a nuclear reactor. This dual-system setup is essential for testing Accident Tolerant Fuel (ATF) coatings, specifically measuring how physical vapor deposition (PVD) materials withstand extreme heat up to 1200°C in the presence of high-concentration water vapor.

This experimental assembly acts as a critical validation tool, allowing researchers to quantify the safety margins of protective coatings by isolating their behavior under the specific thermal and chemical stresses of a reactor failure.

The Mechanics of the Simulation

The Role of the Tube Furnace

The tube furnace serves as the thermal anchor of the experiment, creating a stable constant temperature field.

It is capable of maintaining temperatures up to 1200°C. This capability allows researchers to replicate the intense heat load that fuel rods experience when liquid coolant is lost in a reactor core.

The Role of the Steam Generator

While heat is destructive, steam drives chemical degradation. The steam generator continuously injects high-concentration water vapor into the furnace chamber.

This creates an oxidizing atmosphere that mimics the specific conditions of a LOCA, where water flashes to steam and reacts aggressively with reactor materials.

Critical Metrics for Material Verification

Investigating Oxidation Behavior

The central objective of this setup is to observe high-temperature steam oxidation behavior.

Researchers use this data to determine if PVD coatings can effectively shield the underlying substrate from rapid oxidation. This is the primary defense mechanism required for Accident Tolerant Fuels.

Measuring Weight Gain Rates

Oxidation adds mass to the material. By monitoring weight gain rates, scientists can quantify exactly how fast the coating is reacting with the steam.

Lower weight gain typically correlates with better protection and higher stability, serving as a key pass/fail metric for ATF candidates.

Analyzing Microstructural Evolution

Beyond surface changes, the test reveals the microstructural evolution of the coatings.

High heat and steam can cause grains to grow, phases to change, or layers to delaminate. Understanding these internal structural changes is vital for predicting the long-term integrity of the coating.

Understanding the Trade-offs

Static vs. Transient Conditions

This setup provides a stable constant temperature field, which is excellent for standardized material comparison.

However, it may not fully capture the rapid temperature ramps or pressure spikes associated with the chaotic onset of a real-world LOCA event. It is a steady-state simulation of an accident condition, not a dynamic replay of the accident itself.

Material Focus vs. System Focus

This method is highly specialized for testing material properties like PVD coatings.

It does not account for other LOCA variables such as mechanical vibration, radiation flux, or debris impact. It is a focused chemical and thermal test, not a holistic full-system test.

Making the Right Choice for Your Goal

This simulation setup is the industry standard for screening and verifying advanced nuclear materials. Here is how to apply it to your objectives:

- If your primary focus is material development: Use this setup to screen various PVD compositions, looking for the lowest weight gain and highest microstructural stability at 1200°C.

- If your primary focus is safety licensing: Utilize data from these tests to prove the oxidation resistance of your ATF design, using the "high-temperature steam oxidation behavior" as your core evidence.

This combination of furnace and steam generator remains the definitive method for validating the protective limits of next-generation nuclear fuel coatings.

Summary Table:

| Feature | Function in LOCA Simulation | Key Metric Measured |

|---|---|---|

| Tube Furnace | Provides stable thermal field up to 1200°C | Thermal stability & degradation |

| Steam Generator | Injects high-concentration water vapor | High-temp steam oxidation behavior |

| PVD Coatings | Protective barrier for fuel substrates | Weight gain rate & microstructure |

Secure Your Nuclear Research with KINTEK Precision

Advanced material validation requires uncompromising accuracy. KINTEK provides state-of-the-art Tube, Muffle, Vacuum, and CVD systems designed to meet the rigorous demands of nuclear safety testing and ATF development.

Backed by expert R&D and manufacturing, our high-temp furnaces are fully customizable to simulate the exact thermal and chemical stresses your research requires. Whether you are analyzing microstructural evolution or measuring oxidation rates, our equipment delivers the stable environment needed for definitive results.

Ready to elevate your lab's capabilities? Contact KINTEK today for a custom solution.

Visual Guide

References

- Yuxin Tang, Dewen Tang. High-Temperature Oxidation Behavior of TiN-, Cr-, and TiN–Cr PVD-Coated Zircaloy 4 Alloy at 1200 °C. DOI: 10.3390/ma18081692

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key features of a modern tube furnace? Precision, Control, and Versatility for Advanced Labs

- What are the common uses of vertical fluidized bed tube furnaces in laboratory research? Discover Precision Thermal Solutions

- How does a tube furnace contribute to the CVD of Si-SiO2 composites? Achieve Precise Nanostructure Control

- What is the significance of the heating zone in a vertical tube furnace? Unlock Precision for Material Processing

- What problems existed with early tube furnace designs? Discover the Flaws That Hindered Performance

- How do tube furnaces and isolation valves simulate TCOP experiments? Expert Setup for Thermochemical Oxygen Pumps

- Why are certain high-performance ceramics sintered in a vacuum tube furnace? Achieve Full Density and Purity

- What are the main components of a tube furnace? Essential Parts for Precise High-Temperature Processing