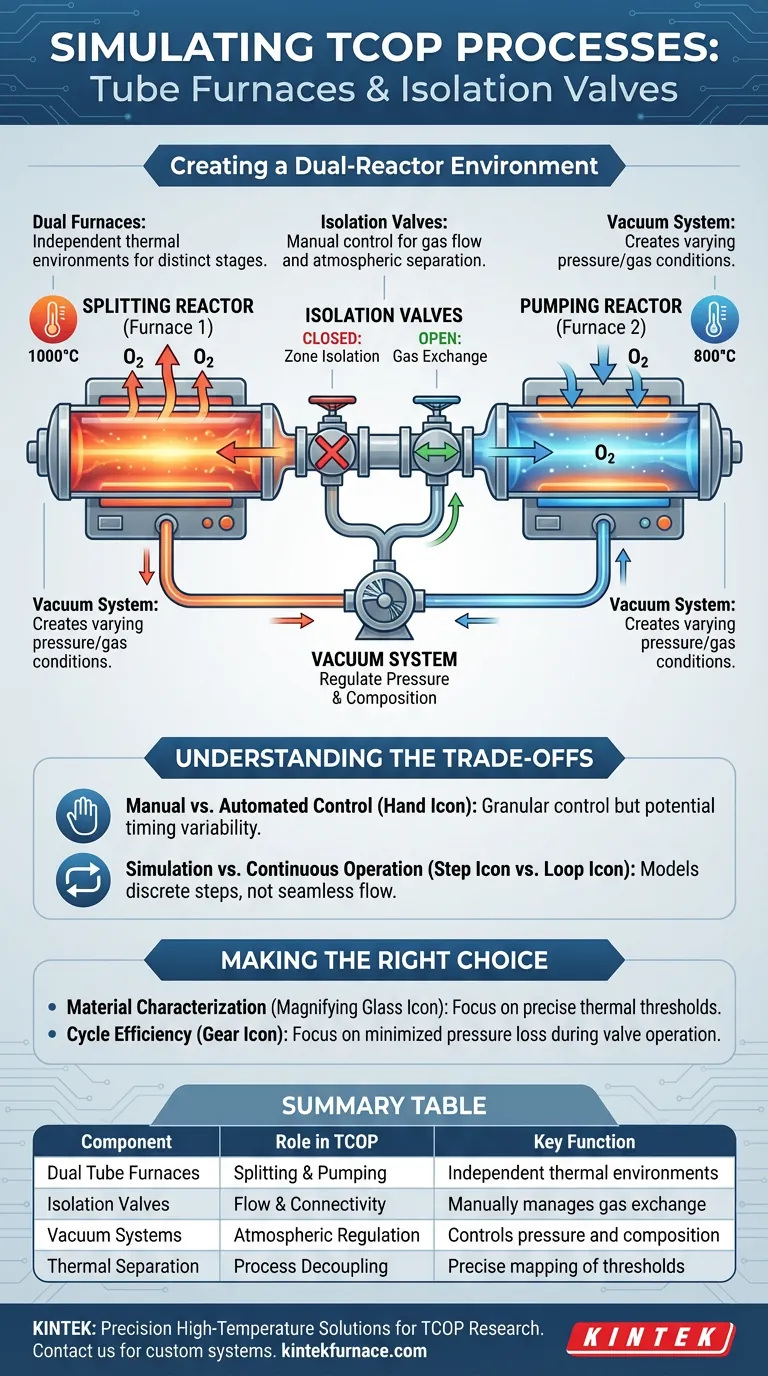

In Thermochemical Oxygen Pump (TCOP) experiments, tube furnaces and isolation valves are arranged to create a dual-reactor simulation that mimics the distinct stages of a thermochemical cycle. Two independent tube furnaces are used to represent the splitting reactor and the pumping reactor separately, while precision manual valves allow researchers to physically connect or isolate these high-temperature zones to control gas flow and pressure.

By decoupling the thermal zones and utilizing manual isolation, this setup enables precise manipulation of pressure and gas composition, allowing for the accurate assessment of oxygen absorption and release performance.

Simulating the Dual-Reactor Environment

The Role of Independent Tube Furnaces

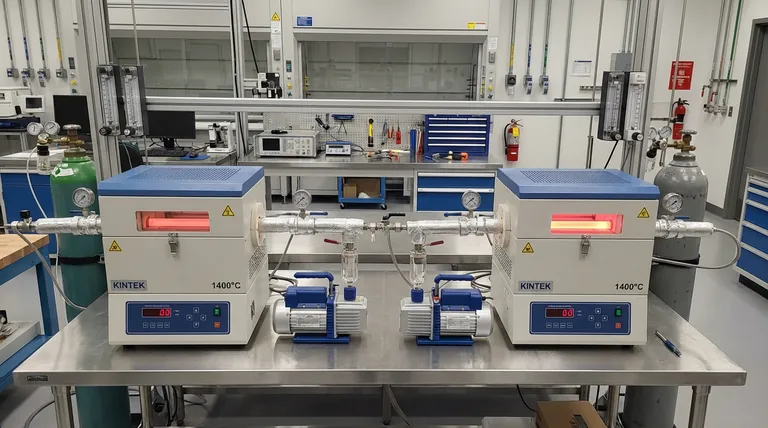

The core of the TCOP experimental setup relies on two independent tube furnaces.

Rather than using a single heating source, this dual-furnace configuration physically separates the process into two distinct thermal environments.

Replicating Specific Reactor Functions

One furnace is designated to simulate the splitting reactor, while the other simulates the pumping reactor.

This separation allows researchers to maintain different thermal conditions simultaneously, mimicking the real-world operational disparity between the two stages of the cycle.

Controlling the Cycle with Isolation Valves

Managing Zone Connectivity

Precision manual valves are placed between the two furnace zones.

These valves serve as the control mechanism, allowing the operator to instantly connect or isolate the atmospheres of the two furnaces.

Simulating Gas Exchange

By opening and closing these valves, researchers can simulate the gas exchange processes that occur during a full thermochemical cycle.

This manual control enables the transfer of gases between the simulated reactors, replicating the flow that would occur in a continuous system.

Regulating Pressure and Composition

The valves work in tandem with vacuum systems to alter the environment within the tubes.

This allows the experiment to run under varying pressures and gas compositions, which is critical for testing how materials behave under stress or changing atmospheric conditions.

Understanding the Trade-offs

Manual vs. Automated Control

The primary reference notes the use of precision manual valves.

While this offers granular control for small-scale experiments, manual operation can introduce variability in timing that might not exist in a fully automated industrial pump.

Simulation vs. Continuous Operation

This setup creates a discontinuous simulation of a continuous process.

While effective for assessing material performance (oxygen absorption and release), the reliance on isolating zones means the setup is modeling discrete steps rather than a seamless, continuous flow.

Making the Right Choice for Your Experiment

To maximize the effectiveness of a TCOP simulation using this setup, consider your specific testing goals:

- If your primary focus is material characterization: Utilize the independent temperature controls of the two furnaces to pinpoint the exact thermal thresholds for oxygen absorption.

- If your primary focus is cycle efficiency: Focus on the precision of your valve operation to minimize pressure loss during the transition between the connected and isolated states.

This configuration provides a robust framework for isolating variables and validating the fundamental chemical performance of your materials.

Summary Table:

| Component | Role in TCOP Simulation | Key Function |

|---|---|---|

| Dual Tube Furnaces | Splitting & Pumping Reactors | Creates independent thermal environments for separate cycle stages. |

| Isolation Valves | Flow & Connectivity Control | Manually manages gas exchange and atmospheric separation between reactors. |

| Vacuum Systems | Atmospheric Regulation | Controls pressure and gas composition to mimic real-world stress conditions. |

| Thermal Separation | Process Decoupling | Allows precise mapping of oxygen absorption and release thresholds. |

Precision High-Temperature Solutions for TCOP Research

Maximize the accuracy of your thermochemical cycles with KINTEK’s industry-leading thermal technology. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique experimental needs.

Whether you are characterizing advanced materials or optimizing oxygen pump efficiency, our high-performance furnaces provide the thermal stability and precision control required for groundbreaking research. Empower your laboratory with KINTEK today—Contact our experts to discuss your custom solution.

Visual Guide

References

- Mathias Pein, Christian Sattler. Thermochemical Oxygen Pumping with Perovskite Reticulated Porous Ceramics for Enhanced Reduction of Ceria in Thermochemical Fuel Production. DOI: 10.1002/aenm.202304454

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is MBE Preferred Over Tube Furnaces for 2D Gallium? Achieve Ultra-Pure Atomic Deposition

- Why Use a High-Precision Weighing System with a Tube Furnace for Magnetite Oxidation Kinetics? Achieve Real-Time Data.

- What environmental conditions must a high-temperature tube furnace provide for MAX phase sintering? Expert Guidelines

- How is heat transferred to the sample in a multi gradient experimental tube furnace? Master Precise Heat Control

- Why are the high-temperature carbonization and activation of sugarcane bagasse typically conducted in a tube furnace?

- What additional features might a split tube furnace have? Boost Your Lab's Precision and Control

- Why is precise heating rate control in a high-temperature tube furnace critical for HyDR? Master Reduction Kinetics

- What are the primary applications of high temperature tube furnaces? Unlock Precise Heat Control for Materials Science