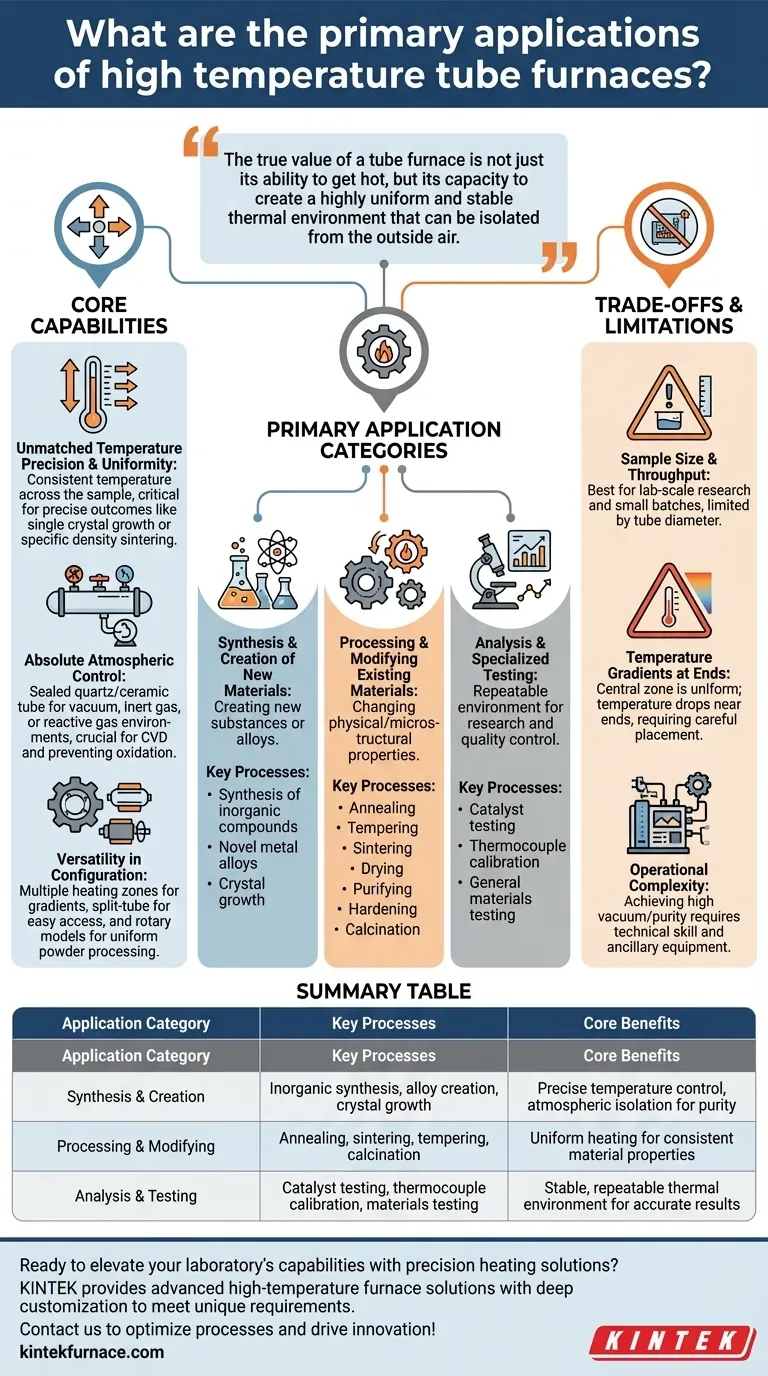

In essence, high-temperature tube furnaces are used for any process that requires precise heating in a tightly controlled environment. Their primary applications fall into three main categories: the synthesis of new materials like alloys and ceramics, the heat treatment of existing materials to alter their properties through processes like annealing or sintering, and the analysis of materials under specific thermal conditions.

The true value of a tube furnace is not just its ability to get hot, but its capacity to create a highly uniform and stable thermal environment that can be isolated from the outside air, enabling processes that would otherwise be impossible.

The Core Capabilities of a Tube Furnace

To understand why tube furnaces are used for so many different tasks, you must first understand their three fundamental capabilities. These features are what separate them from a simple oven or kiln.

Unmatched Temperature Precision and Uniformity

A tube furnace's cylindrical heating chamber and advanced control systems create an exceptionally uniform hot zone. This means the temperature is consistent across the sample.

This precision is critical for processes where slight temperature variations can ruin the outcome, such as growing a single crystal or sintering a ceramic part to a specific density.

Absolute Atmospheric Control

The defining feature of a tube furnace is the tube itself, typically made of ceramic or quartz. This tube can be sealed at the ends.

This sealed environment allows you to remove the air and create a vacuum, or to introduce specific gases. You can use an inert gas like argon to prevent oxidation or a reactive gas to participate in a chemical reaction, such as in Chemical Vapor Deposition (CVD).

Versatility in Configuration

Tube furnaces are not one-size-fits-all. They can be configured with multiple heating zones to create a temperature gradient or an extended uniform zone.

They also come in "split-tube" designs that open like a clamshell for easy placement of samples, or rotary models that tumble powders for uniform processing.

Primary Application Categories

The core capabilities of precision, control, and versatility directly enable the furnace's main applications in science and industry.

Synthesis and Creation of New Materials

This category involves creating a new substance through chemical reaction or phase change, often at high temperatures.

Applications like the synthesis of inorganic compounds, creation of novel metal alloys, and crystal growth all rely on the furnace's ability to maintain a precise temperature profile and a controlled atmosphere to drive the desired reactions and prevent contamination.

Processing and Modifying Existing Materials

This is the largest category of use, where the goal is to change a material's physical or microstructural properties, not its chemical composition.

Processes like annealing (softening metals), tempering (toughening steel), and sintering (fusing powders into a solid mass) depend on executing exact time-and-temperature recipes. The furnace's uniformity ensures the entire part receives the same treatment.

Other common applications here include drying, purifying, hardening, and calcination.

Analysis and Specialized Testing

A tube furnace provides a repeatable and stable environment, making it an ideal platform for research and quality control.

It is used for catalyst testing, where a gas is passed over a heated catalyst to measure its performance. It's also used for thermocouple calibration and general materials testing to see how a substance behaves under extreme, controlled heat.

Understanding the Trade-offs and Limitations

While highly capable, a tube furnace is not the solution for every heating task. Objectivity requires understanding its limitations.

Sample Size and Throughput

Tube furnaces are best suited for laboratory-scale research, prototyping, and small-batch production. The diameter of the tube inherently limits the size of the object you can process.

For high-volume manufacturing, larger industrial batch furnaces or conveyor furnaces are more efficient.

Temperature Gradients at the Ends

The central zone of the tube is highly uniform, but the temperature naturally drops off near the ends. This must be accounted for in sample placement.

While multi-zone furnaces can extend the uniform hot zone, they add cost and complexity.

Operational Complexity

Achieving a true high-vacuum or an ultra-pure gas atmosphere is not trivial. It requires ancillary equipment like vacuum pumps, gas flow controllers, and proper sealing techniques, which demands a degree of technical skill to operate correctly.

Making the Right Choice for Your Goal

Ultimately, the decision to use a tube furnace should be based on whether your process demands its unique capabilities.

- If your primary focus is research and development: A tube furnace is an indispensable tool for exploring new materials and processes due to its precision and atmospheric control.

- If your primary focus is improving material properties: Use a tube furnace for heat treatments like annealing or sintering where achieving a specific microstructure is critical.

- If your primary focus is high-purity processing: The sealed environment is essential for preventing contamination and oxidation during synthesis, purification, or degassing.

A high-temperature tube furnace is the definitive tool for any process that demands precise thermal and atmospheric command over a material.

Summary Table:

| Application Category | Key Processes | Core Benefits |

|---|---|---|

| Synthesis and Creation | Inorganic compound synthesis, alloy creation, crystal growth | Precise temperature control, atmospheric isolation for purity |

| Processing and Modifying | Annealing, sintering, tempering, calcination | Uniform heating for consistent material properties |

| Analysis and Testing | Catalyst testing, thermocouple calibration, materials testing | Stable, repeatable thermal environment for accurate results |

Ready to elevate your laboratory's capabilities with precision heating solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your processes and drive innovation in your research or production!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What materials are used for the tube chamber in tubular furnaces? Choose the Right Tube for Your Lab's High-Temp Needs

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- What industries benefit from the use of tube furnaces? Unlock Precision in Semiconductor and Battery Tech

- Why are tubular furnaces important in material testing and research? Unlock Precision for Advanced Materials Development