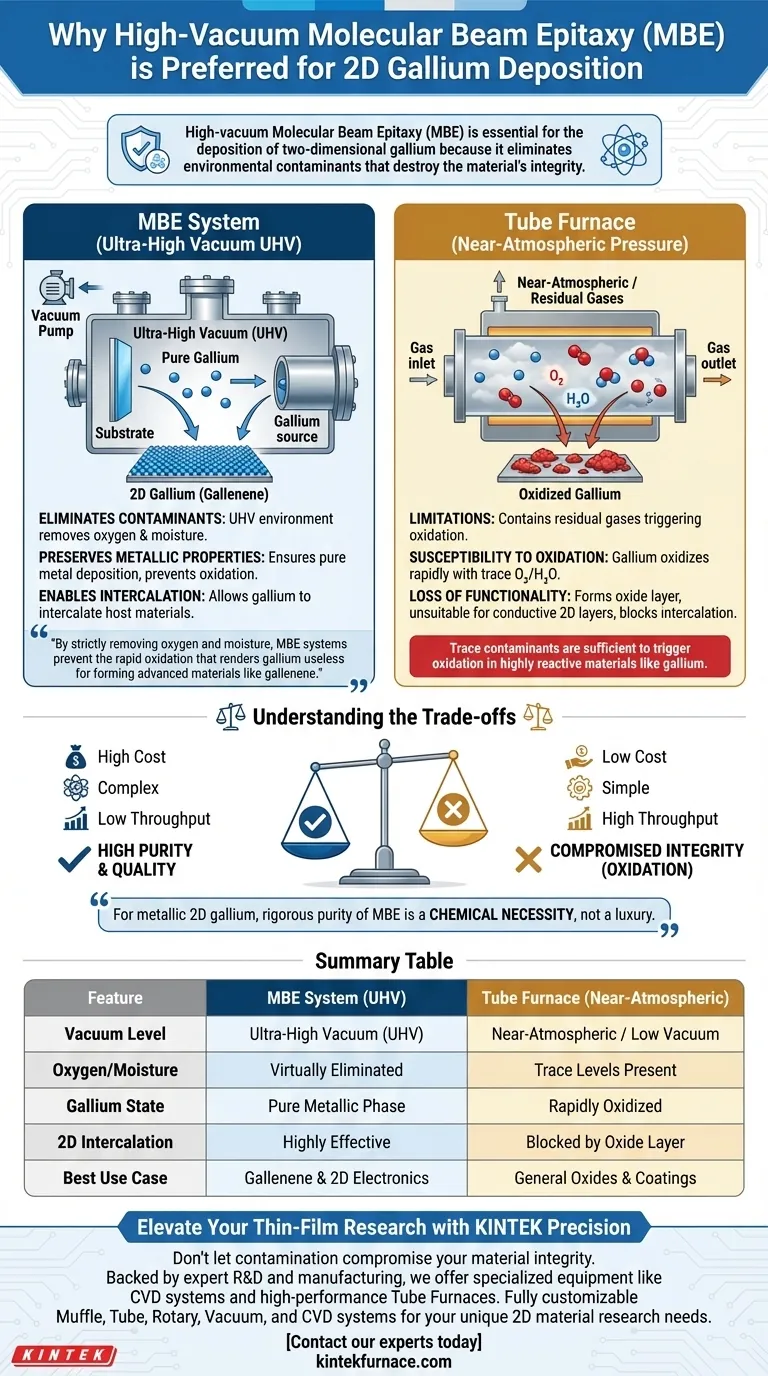

High-vacuum Molecular Beam Epitaxy (MBE) is essential for the deposition of two-dimensional gallium because it eliminates the environmental contaminants that destroy the material's integrity. Unlike near-atmospheric pressure tube furnaces, an MBE system provides an ultra-high vacuum (UHV) environment that completely removes ambient oxygen and moisture. This is the only reliable way to prevent immediate oxidation and ensure gallium retains the metallic properties necessary for successful atomic-layer intercalation.

The success of depositing two-dimensional gallium hinges entirely on environmental purity. By strictly removing oxygen and moisture, MBE systems prevent the rapid oxidation that renders gallium useless for forming advanced materials like gallenene.

The Challenge of Gallium Stability

Susceptibility to Oxidation

Gallium is highly sensitive to its environment. When exposed to even trace amounts of oxygen or moisture, it oxidizes rapidly.

The Limitations of Tube Furnaces

Near-atmospheric pressure tube furnaces, while useful for many processes, typically contain residual gases. These trace contaminants are sufficient to trigger oxidation in highly reactive materials like gallium.

Loss of Functionality

Once gallium oxidizes, it loses the specific metallic characteristics required for electronic applications. The formation of an oxide layer fundamentally changes the material's behavior, rendering it unsuitable for creating conductive 2D layers.

Why Ultra-High Vacuum (UHV) is Non-Negotiable

Eliminating Contaminants

The primary advantage of an MBE system is the creation of an Ultra-High Vacuum (UHV). This environment drastically reduces the mean free path of gas molecules, effectively removing oxygen and water vapor from the chamber.

Preserving Metallic Properties

In a UHV environment, gallium atoms can travel to the substrate without colliding with contaminants. This ensures that the gallium deposited is pure metal, rather than a gallium oxide compound.

Enabling Intercalation Reactions

For applications involving gallenene, gallium atoms must intercalate (insert themselves) between layers of a host material, such as graphene. This atomic-layer intercalation relies on the chemical potential of pure gallium; oxidation acts as a barrier that blocks this reaction.

Understanding the Trade-offs

Cost and Complexity

While MBE is chemically superior for this application, it is significantly more resource-intensive. MBE systems are expensive to install and complex to maintain compared to the relative simplicity of a tube furnace.

Throughput vs. Purity

Tube furnaces allow for faster, higher-volume processing. However, for 2D gallium, the "trade-off" is absolute: you sacrifice the ability to create the material at all in exchange for operational simplicity. MBE offers lower throughput but is currently the only path to the required purity.

Making the Right Choice for Your Goal

If you are attempting to synthesize two-dimensional gallium, the deposition method dictates the viability of your final product.

- If your primary focus is synthesizing high-quality gallenene: You must use an MBE system to prevent oxidation and enable the necessary intercalation reactions with graphene.

- If your primary focus is general oxide deposition or low-cost coatings: A near-atmospheric tube furnace may be acceptable, but understand that it will not produce metallic 2D gallium.

For the specific goal of creating metallic, two-dimensional gallium structures, the rigorous purity of an MBE system is not a luxury, but a chemical necessity.

Summary Table:

| Feature | MBE System (UHV) | Tube Furnace (Near-Atmospheric) |

|---|---|---|

| Vacuum Level | Ultra-High Vacuum (UHV) | Near-Atmospheric / Low Vacuum |

| Oxygen/Moisture | Virtually Eliminated | Trace Levels Present |

| Gallium State | Pure Metallic Phase | Rapidly Oxidized |

| 2D Intercalation | Highly Effective | Blocked by Oxide Layer |

| Best Use Case | Gallenene & 2D Electronics | General Oxides & Coatings |

Elevate Your Thin-Film Research with KINTEK Precision

Don't let contamination compromise your material integrity. Whether you require the extreme purity of CVD systems or high-performance Tube Furnaces for scalable processes, KINTEK provides the specialized equipment needed for advanced synthesis.

Backed by expert R&D and manufacturing, we offer a comprehensive range of lab high-temp systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique 2D material research needs.

Ready to achieve superior deposition results? Contact our experts today to find the perfect thermal solution for your laboratory.

Visual Guide

References

- Emanuele Pompei, Stefano Veronesi. Novel Structures of Gallenene Intercalated in Epitaxial Graphene. DOI: 10.1002/smll.202505640

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How does a laboratory tube furnace facilitate the control of pore structures? Master Precision Porous Carbon Synthesis

- What is the function of a tube reduction furnace in PtLaOx@S-1 catalysts? Achieve Precise Chemical Restructuring

- What role does a tube furnace play in tantalum capacitor recycling? Enhancing Metal Recovery Through Pyrolysis

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- Why is a tube furnace with precise temperature control critical for the preparation of Palladium Borosulfates?

- How does a tube furnace work? Master Precise Heat and Atmosphere Control

- What is the technical significance of phased high-temperature annealing in a tube furnace for 3D Porous Graphene?

- What is the purpose of insulation in a 70mm tube furnace? Ensure Precision and Efficiency in Your Lab