At its core, a modern tube furnace is defined by its ability to create a precisely controlled, high-temperature environment within a contained space. The key features that enable this are exceptional temperature uniformity, robust atmosphere control for vacuum or gas environments, and intelligent digital controllers that ensure process accuracy and repeatability. These elements work in concert to move beyond simple heating and provide a powerful tool for advanced material processing.

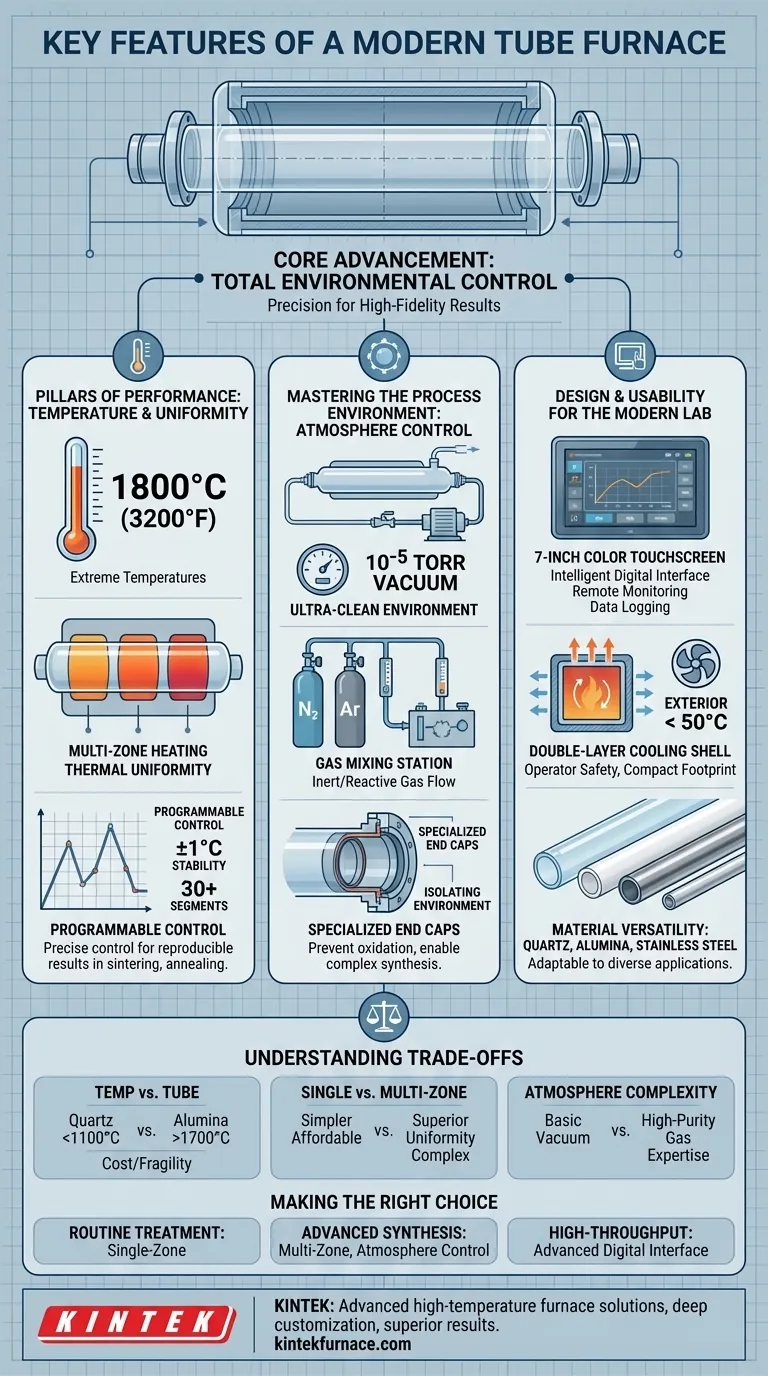

The true advancement in modern tube furnaces is not just the ability to reach high temperatures, but the integration of features that provide total environmental control. This precision is what enables reproducible, high-fidelity results in research and production.

The Pillars of Performance: Temperature and Uniformity

The primary function of any furnace is to generate and maintain heat. Modern tube furnaces excel not just in the intensity of that heat, but in the precision with which it is applied.

Reaching Extreme Temperatures

Modern furnaces are engineered for high-temperature performance, with continuous operating temperatures often reaching 1760°C (3200°F) and maximums pushing 1800°C. This capability is essential for processing advanced materials like high-purity ceramics and alloys that require sintering or annealing at extreme temperatures.

The Critical Role of Thermal Uniformity

Simply being hot is not enough; the heat must be consistent across the entire sample. Thermal uniformity ensures that every part of the material inside the tube experiences the same temperature, which is critical for consistent results in processes like chemical vapor deposition (CVD) or annealing. Furnaces achieve this through single-zone or, for superior control, multi-zone heating configurations.

Precision Through Programmable Control

Repeatability is paramount in scientific and industrial work. Modern furnaces feature fully programmable controllers, often with 30 or more segments. This allows users to design complex thermal profiles with specific ramp rates, dwell times, and cooling sequences, all with a temperature stability often within ±1°C.

Mastering the Process Environment: Atmosphere Control

Many advanced material processes cannot occur in ambient air. A key feature of modern tube furnaces is the ability to tightly control the atmosphere within the processing tube.

Operating in a Vacuum

To prevent oxidation or remove contaminants, processes are often conducted under vacuum. Modern systems can be equipped with pumps and sealed end caps to achieve vacuum levels down to 10⁻⁵ torr, creating an ultra-clean environment for sensitive reactions.

Introducing Inert or Reactive Gases

For applications like nitriding or creating an oxygen-free environment, furnaces are equipped with gas flow systems. These allow for the introduction of specific gases, such as nitrogen or argon. More advanced systems even include gas mixing stations to deliver precise blends of reactive gases for complex synthesis processes.

Sealing the System with End Caps

Atmosphere control is made possible by a system of specialized end caps and flanges. These components seal the ends of the process tube and provide the necessary ports for connecting vacuum pumps and gas lines, effectively isolating the internal environment.

Design and Usability for the Modern Lab

Beyond core performance, modern tube furnaces incorporate features that improve safety, ease of use, and versatility.

Intelligent Digital Interfaces

Outdated analog controls have been replaced by intuitive interfaces, such as a 7-inch color touchscreen. Many systems come with preset sintering curves and support software for remote monitoring and data logging, which simplifies operation and reduces the risk of human error.

Operator Safety and Footprint

Safety is a primary design concern. A double-layer steel cooling shell, often with internal fans, keeps the exterior surface temperature below 50°C, even when the interior is at its maximum. Their compact, bench-top design also helps conserve valuable lab space.

Material and Application Versatility

These furnaces are designed to be flexible. They can accommodate process tubes made from various materials like quartz, alumina, or stainless steel, depending on the temperature and chemical requirements of the experiment. This makes them adaptable for a wide range of applications, from metals and ceramics to advanced nanomaterials.

Understanding the Trade-offs

Selecting a furnace requires balancing capability with complexity and cost. Understanding the inherent trade-offs is key to making an informed decision.

Temperature vs. Tube Material

The maximum operating temperature is directly limited by the process tube material. Quartz tubes are cost-effective but generally limited to around 1100°C. Reaching temperatures of 1700°C or higher requires a high-purity alumina ceramic tube, which is more expensive and fragile.

Single-Zone vs. Multi-Zone

A single-zone furnace is simpler and more affordable but may struggle to maintain perfect uniformity over a long heated length. Multi-zone furnaces offer superior temperature control and uniformity by using multiple independent heating elements and controllers, but this comes at a significantly higher cost and complexity.

Atmosphere Control Complexity

A basic vacuum or inert gas setup is relatively straightforward. However, systems designed for high-purity gas mixing or ultra-high vacuum add substantial cost and require greater operator expertise to maintain and operate correctly without introducing leaks or contamination.

Making the Right Choice for Your Application

Your specific goal should dictate which features you prioritize.

- If your primary focus is routine heat treatment or simple annealing: A reliable single-zone furnace with basic programmable controls is often sufficient and cost-effective.

- If your primary focus is advanced material synthesis (e.g., CVD or crystal growth): A multi-zone furnace with comprehensive atmosphere control, including vacuum and gas mixing systems, is essential for precision and repeatability.

- If your primary focus is high-throughput or process development: Prioritize a furnace with an advanced digital interface, software for data logging, and pre-programmable recipes to ensure consistency and efficiency.

Understanding these core features empowers you to select a tool that doesn't just meet temperature specifications, but truly enables your specific scientific or industrial goal.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Temperature Uniformity | Consistent heat across the sample via multi-zone heating | Ensures reliable results in processes like CVD and annealing |

| Atmosphere Control | Vacuum or gas environments with precise gas mixing | Prevents oxidation and enables complex synthesis |

| Digital Control | Programmable controllers with touchscreen interfaces | Enhances repeatability and reduces human error |

| Safety and Design | Double-layer cooling shell and compact bench-top footprint | Protects operators and saves lab space |

| Material Versatility | Compatible with quartz, alumina, or stainless steel tubes | Adapts to various temperature and chemical requirements |

Ready to elevate your lab's capabilities with a custom tube furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental requirements. Whether you're in research, production, or process development, our expertise ensures precise temperature control, atmosphere management, and user-friendly designs for superior results. Contact us today to discuss how we can support your specific applications and drive innovation in your work!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision