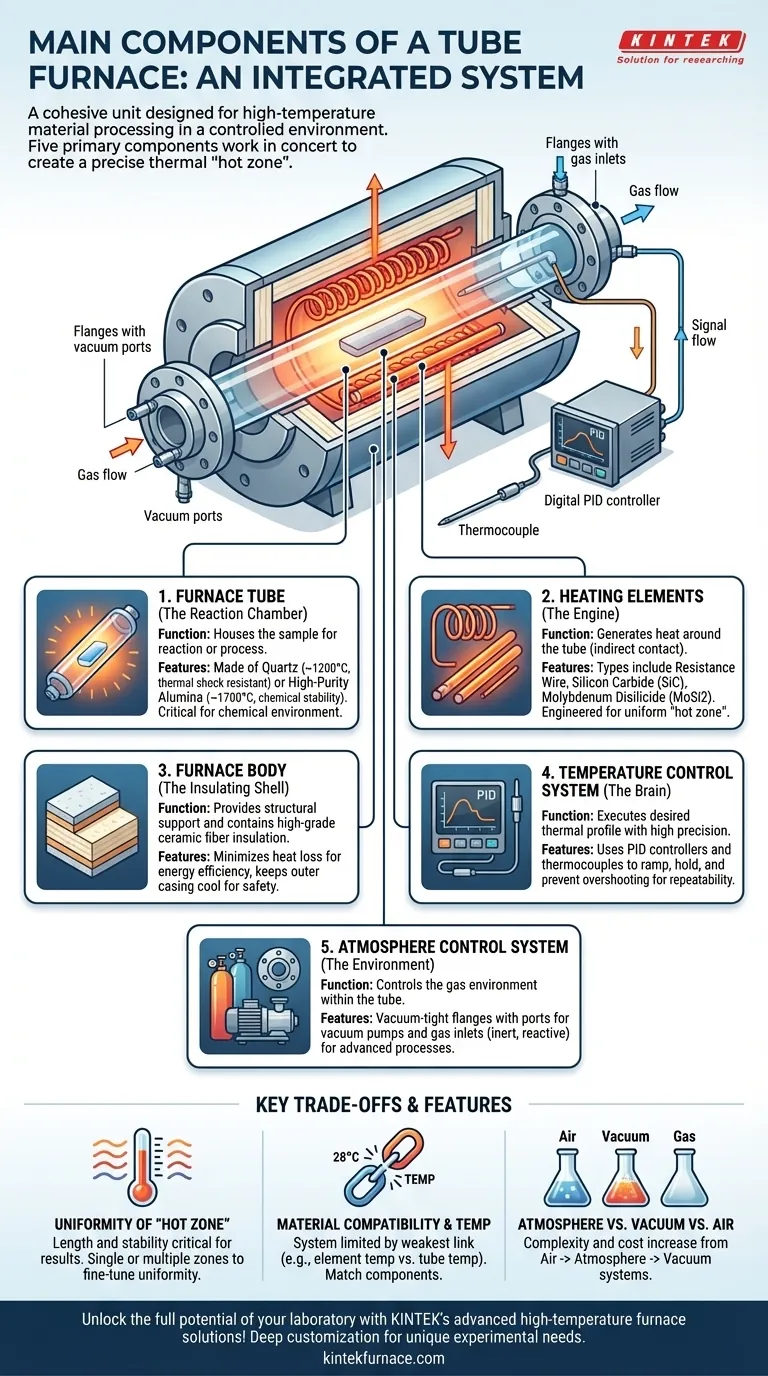

At its core, a tube furnace is an integrated system designed for high-temperature material processing in a controlled environment. The five primary components that work together to achieve this are the furnace tube, heating elements, the furnace body, a temperature control system, and, in many cases, an atmosphere or gas circulation system. These parts are not independent but function as a cohesive unit to create a precise thermal environment.

A tube furnace should be understood not as a collection of parts, but as a complete system. Each component—from the reaction tube to the control electronics—is chosen and designed to work in concert, creating a highly uniform and controllable "hot zone" for sophisticated material processing.

The Core Components of a Tube Furnace

A tube furnace's primary function is to apply uniform, precise heat to a sample. This is accomplished through the interplay of several critical components, each with a distinct role.

The Furnace Tube (The Reaction Chamber)

This is the central component where the sample is placed and the reaction or process occurs. It is a hollow cylinder that passes through the heated section of the furnace.

The material of the tube is critical and chosen based on the required temperature and chemical environment. Common materials include quartz (for use up to ~1200°C and good thermal shock resistance) and high-purity alumina (for higher temperatures, up to ~1700°C, and excellent chemical stability).

The Heating Elements (The Engine)

Positioned around the exterior of the furnace tube, these elements generate the heat. They are never in direct contact with the sample, which ensures a clean processing environment.

The type of element dictates the furnace's maximum temperature. Common types include resistance wire (like Kanthal) for lower temperatures, and silicon carbide (SiC) or molybdenum disilicide (MoSi2) rods for higher-temperature applications. Their arrangement is engineered to create a uniform "hot zone" along a specific length of the tube.

The Furnace Body (The Insulating Shell)

The furnace body is the exterior casing that houses the heating elements and furnace tube. Its role is twofold: it provides structural support and, more importantly, contains layers of high-grade ceramic fiber insulation.

This insulation is crucial for minimizing heat loss, which improves energy efficiency and allows the furnace to reach high temperatures. It also keeps the outer casing cool to the touch, ensuring operator safety.

The Temperature Control System (The Brain)

This is the electronic heart of the furnace, responsible for executing the desired thermal profile with high precision. It consists of a temperature sensor, typically a thermocouple, and a controller.

Modern furnaces use sophisticated PID (Proportional-Integral-Derivative) controllers to actively manage power to the heating elements. This allows them to ramp temperature at a set rate, hold a precise setpoint, and prevent overshooting, ensuring process repeatability and safety.

The Atmosphere Control System (The Environment)

For processes that cannot be performed in ambient air, an atmosphere control system is essential. This system seals the ends of the furnace tube with vacuum-tight flanges.

These flanges include ports for connecting a vacuum pump to evacuate air and gas inlets to introduce a specific environment, such as an inert gas (e.g., argon, nitrogen) or a reactive gas. This capability is what distinguishes a tube furnace as a tool for advanced materials science.

Understanding the Trade-offs and Key Features

Choosing or operating a tube furnace involves understanding the compromises inherent in its design. The capabilities of one component directly impact the requirements of another.

Uniformity of the "Hot Zone"

The "hot zone" is the section of the tube that maintains a stable, uniform temperature. The length and uniformity of this zone are critical for process results, especially when processing larger samples. Furnaces may have a single heating zone or multiple zones, each with its own controller, to extend or fine-tune the uniformity of the hot zone.

Material Compatibility and Temperature

The maximum operating temperature is a primary specification, but it is limited by the weakest link in the system. An alumina tube can withstand 1700°C, but if the heating elements can only reach 1200°C, the system is limited to 1200°C. Likewise, a quartz tube should not be used in a furnace capable of 1500°C, as it would fail.

Atmosphere vs. Vacuum vs. Air

A simple tube furnace may only be designed for heating in air. An atmosphere furnace adds the ability to flow inert or reactive gases. A vacuum furnace adds a vacuum pump and compatible flanges to remove atmosphere entirely. Each level of control adds complexity and cost to the system.

Making the Right Choice for Your Application

Your specific goal will determine which furnace configuration is necessary.

- If your primary focus is basic heat treatment or calcination in air: A simple furnace with a robust temperature controller and a suitable alumina or quartz tube is sufficient.

- If your primary focus is annealing sensitive materials or preventing oxidation: You require a furnace with a complete atmosphere control system for purging with inert gas.

- If your primary focus is thin-film deposition (CVD) or degassing: A high-vacuum system with precise gas flow controllers and an extended, uniform hot zone is essential.

- If your primary focus is reaching extreme temperatures (>1400°C): You must select a furnace equipped with high-temperature elements (SiC or MoSi2) and a high-purity alumina tube.

Ultimately, understanding how these core components work together empowers you to select the right tool and design a successful thermal process.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Tube | Houses the sample and reaction | Made of quartz (up to 1200°C) or alumina (up to 1700°C) for chemical stability |

| Heating Elements | Generates heat around the tube | Types include resistance wire, SiC, or MoSi2 for uniform hot zones |

| Furnace Body | Provides insulation and structural support | Uses ceramic fiber to minimize heat loss and ensure safety |

| Temperature Control System | Manages thermal profiles | Includes PID controllers and thermocouples for precision |

| Atmosphere Control System | Controls gas environment | Features vacuum pumps and gas inlets for inert or reactive atmospheres |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored options like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how our expertise can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision