In a laboratory setting, vertical fluidized bed tube furnaces are primarily used for the precise thermal treatment of materials under highly controlled atmospheric conditions. Key applications include annealing metals to improve ductility, testing the performance of catalysts, sintering powders into solid masses, and studying the thermal properties and phase transformations of advanced materials.

The defining feature of a vertical fluidized bed tube furnace is its ability to deliver exceptionally uniform and efficient heat transfer. This makes it the ideal choice for any research application where precise temperature control and consistent sample treatment are non-negotiable.

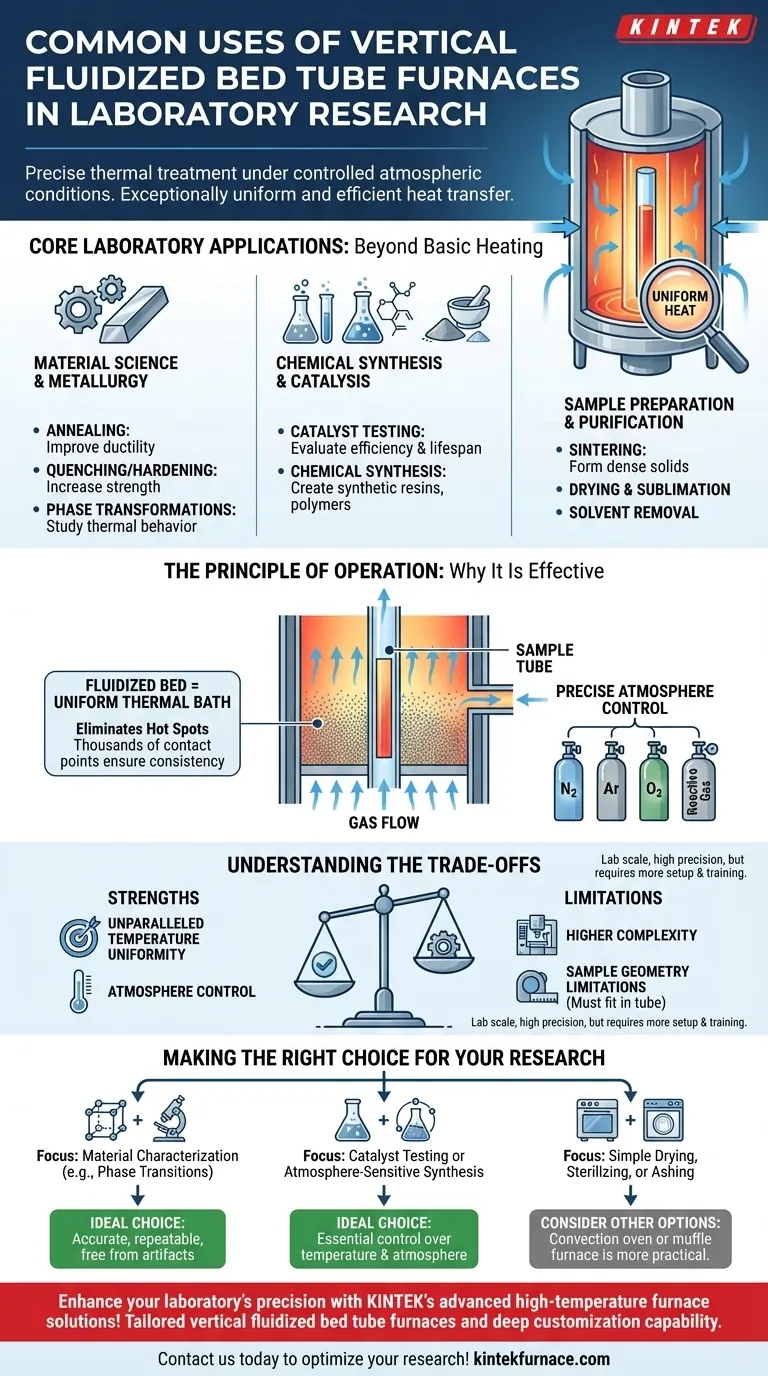

Core Laboratory Applications: Beyond Basic Heating

While many furnaces can achieve high temperatures, a vertical fluidized bed furnace excels at specific, sensitive processes where thermal accuracy is paramount.

Material Science and Metallurgy

These furnaces are indispensable for heat-treating samples to modify their physical and mechanical properties. This includes annealing, which makes metals more malleable, and quenching or hardening to increase their strength.

The furnace's uniform heating is critical for studying phase transformations and other thermal behaviors, ensuring that observed changes are a true property of the material, not an artifact of uneven temperature.

Chemical Synthesis and Catalysis

Researchers use these furnaces extensively for catalyst testing. The ability to maintain a precise temperature and control the gas environment (e.g., inert or reactive) is essential for evaluating a catalyst's efficiency and lifespan.

They are also used for small-scale chemical synthesis, such as creating synthetic resins or other polymers where a specific thermal profile is required to drive the reaction.

Sample Preparation and Purification

The furnace's consistent heat is perfect for processes like sintering, where fine powders are heated to form a dense solid without melting. This is common in ceramics and powder metallurgy.

Other preparatory tasks include drying sensitive samples, performing sublimation to purify compounds, and solvent removal or polymer curing where controlled evaporation is key.

The Principle of Operation: Why It Is So Effective

The value of this furnace lies in its unique method of heat transfer, which solves a common problem in thermal processing.

Fluidization for Uniform Temperature

The core of the system is a bed of fine, inert particles (like alumina sand). A controlled upward flow of gas suspends these particles, causing them to behave like a boiling fluid.

This "fluidized bed" surrounds the vertical sample tube, acting as a perfect thermal bath. It transfers heat to the sample through thousands of points of contact, ensuring outstanding temperature uniformity along the entire length of the sample.

Eliminating Hot Spots

Conventional furnaces often rely on radiant heating elements, which can create hot spots and temperature gradients across a sample. This leads to inconsistent results.

The fluidized bed's design completely eliminates this issue, providing a level of thermal consistency that is difficult to achieve with other furnace types.

Precise Atmosphere Control

The gas used to fluidize the bed also serves as the sample's atmosphere. Researchers can easily use air, an inert gas (like argon or nitrogen), or a specific reactive gas mixture.

This integrated atmosphere control is vital for preventing unwanted oxidation and studying material behavior in specific chemical environments.

Understanding the Trade-offs

While powerful, this technology is not a universal solution. Understanding its context is key to using it appropriately.

Industrial vs. Laboratory Scale

You will often hear about fluidized beds being used in massive industrial applications like power generation or petroleum refining.

The laboratory instrument is a scaled-down version of this same technology. It applies the same principles of uniform heating and efficiency to the small-scale, high-precision world of research and development.

Higher Complexity

Compared to a simple box or muffle furnace, a fluidized bed system is more complex. It involves gas flow controllers, regulators, and the management of the fluidizing medium.

This means it may require more setup and operator training to run effectively.

Sample Geometry Limitations

The primary constraint is that the sample or vessel must fit within the furnace's vertical tube. This makes it unsuitable for large, bulky, or irregularly shaped objects that would be more easily processed in a chamber furnace.

Making the Right Choice for Your Research

To decide if this furnace is right for your work, align its core strengths with your experimental goals.

- If your primary focus is material characterization (e.g., studying phase transitions): The unparalleled temperature uniformity ensures your results are accurate, repeatable, and free from thermal artifacts.

- If your primary focus is catalyst testing or atmosphere-sensitive synthesis: The integrated control over both temperature and atmosphere is essential for studying reaction kinetics and outcomes reliably.

- If your primary focus is simple drying, sterilizing, or ashing: A less complex convection oven or standard muffle furnace is likely a more practical and cost-effective solution.

Ultimately, choosing a vertical fluidized bed furnace is a decision to prioritize thermal precision and uniformity above all else in your experimental design.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Material Science | Annealing, quenching, phase transformation studies |

| Chemical Synthesis | Catalyst testing, polymer synthesis |

| Sample Preparation | Sintering, drying, sublimation, solvent removal |

Enhance your laboratory's precision with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored vertical fluidized bed tube furnaces, muffle furnaces, tube furnaces, rotary furnaces, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures your unique experimental requirements are met for superior thermal processing. Contact us today to discuss how our solutions can optimize your research and drive innovation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation