In environmental science and testing, tube furnaces serve two primary functions: the precise analysis of environmental samples and the thermal treatment of hazardous materials. They are used to break down soil, waste, and water residues to determine their chemical composition, and also to incinerate or transform waste and sludge into safer, more manageable substances.

The core value of a tube furnace in an environmental lab is its ability to create a highly controlled and isolated high-temperature environment. This precision allows scientists to either deconstruct a sample for accurate analysis or transform it for safe disposal.

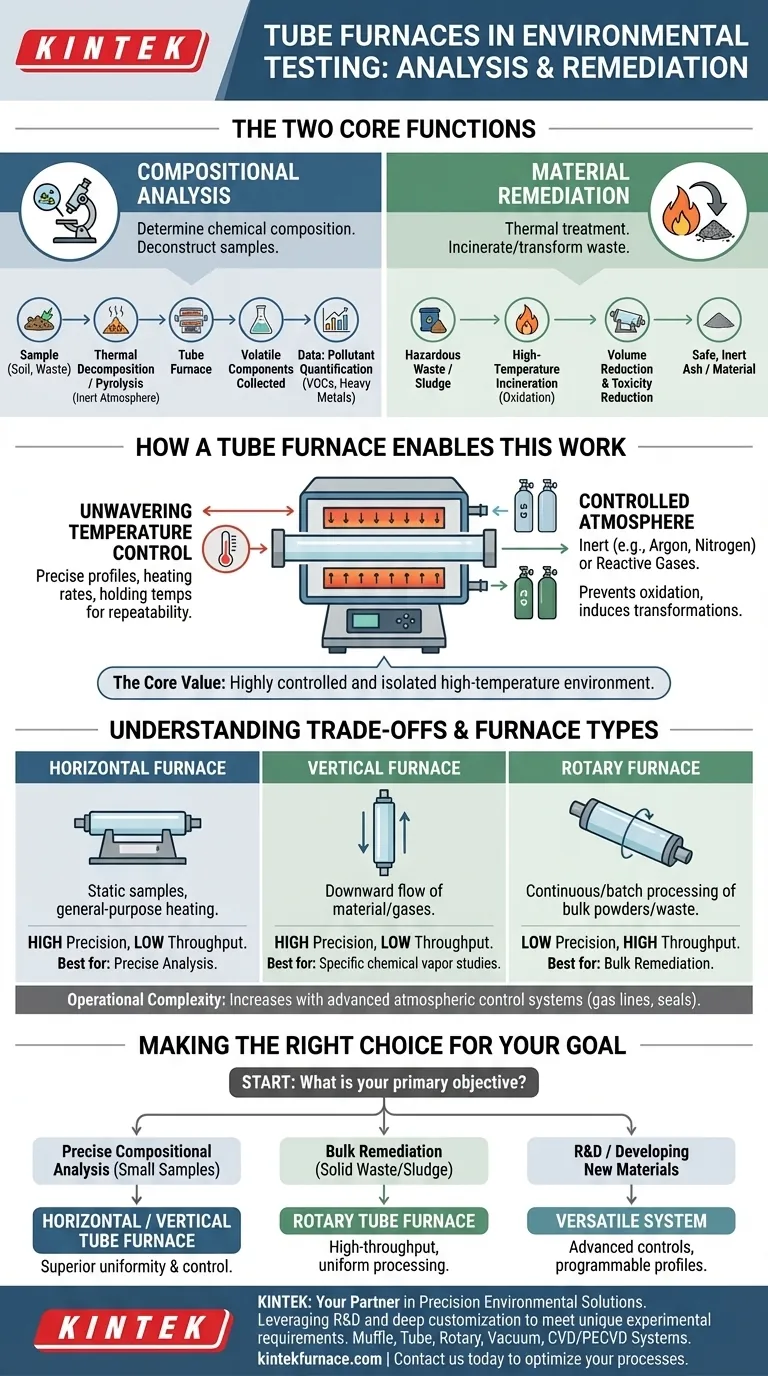

The Two Core Functions in Environmental Testing

A tube furnace is more than just an oven; it is a precision instrument. Its enclosed, tubular chamber enables exacting control over the conditions applied to a sample, which is critical for both analysis and remediation.

Compositional Analysis

To understand the environmental impact of a substance, you must first know what it is made of. Tube furnaces are essential for preparing samples for this analysis.

The primary method used is thermal decomposition or pyrolysis. By heating a sample (like soil, sludge, or industrial waste) in a controlled atmosphere without oxygen, the furnace breaks down complex organic materials into simpler, volatile components that can be collected and identified.

This process is vital for quantifying pollutants like volatile organic compounds (VOCs), determining the total organic content of soil, or isolating heavy metals from a sediment sample for further analysis.

Material Remediation

Beyond analysis, tube furnaces are used for the active treatment of waste materials. This is a form of environmental remediation.

High-temperature incineration is a key application. For example, rotary tube furnaces are used to process large volumes of solid waste or sludge. The constant rotation ensures all material is heated evenly and completely.

This process can transform hazardous organic waste into inert ash, significantly reducing its volume and toxicity. In some cases, the energy released during incineration can even be captured and repurposed.

How a Tube Furnace Enables This Work

The unique design of a tube furnace provides two capabilities that are essential for repeatable and reliable environmental testing: precise temperature control and a managed atmosphere.

Unwavering Temperature Control

Tube furnaces allow operators to program specific temperature profiles, including the rate of heating, the holding temperature, and the cooling rate. This repeatability is the bedrock of scientific testing, ensuring that results from different samples can be compared accurately.

Controlled Atmosphere

The sealed tube chamber allows for complete control over the gaseous environment surrounding the sample. The chamber can be filled with an inert gas (like argon or nitrogen) to prevent unwanted oxidation during pyrolysis.

Alternatively, a reactive gas can be introduced to study or induce specific chemical transformations. This atmospheric control is what separates a tube furnace from a simple oven and enables sophisticated chemical analysis and material processing.

Understanding the Trade-offs

While powerful, choosing and operating a tube furnace requires understanding its inherent trade-offs.

Sample Throughput vs. Precision

Rotary tube furnaces are excellent for processing large volumes of bulk material like soil or waste, but they offer less granular control over specific sections of the sample. Static horizontal or vertical furnaces provide more precise, uniform heating for smaller, individual samples critical for research and analysis.

Furnace Type and Application

The orientation and design of the furnace must match the task.

- Horizontal furnaces are workhorses for general-purpose heating of static samples.

- Vertical furnaces are better suited for processes where material or gases must flow downwards, like in certain types of chemical vapor deposition or decomposition studies.

- Rotary furnaces are specifically designed for continuous or batch processing of powders and non-uniform materials, making them ideal for bulk remediation.

Operational Complexity

Achieving and maintaining a controlled atmosphere adds complexity and cost. It requires gas lines, flow meters, and sealed flanges, all of which demand careful operation and maintenance to prevent leaks and ensure the purity of the internal environment.

Making the Right Choice for Your Goal

Your specific environmental objective will determine the most suitable type of furnace.

- If your primary focus is precise compositional analysis of small samples: A static horizontal or vertical tube furnace offers the superior temperature uniformity and atmospheric control needed for repeatable research.

- If your primary focus is bulk remediation of solid waste or sludge: A rotary tube furnace is specifically designed for the high-throughput, uniform processing of non-homogenous materials.

- If your primary focus is developing new catalysts or advanced materials for remediation: A versatile system with advanced atmospheric controls and a programmable temperature profile is essential for experimental research.

Ultimately, selecting the right tube furnace transforms it from a simple heat source into a precise instrument for environmental discovery and remediation.

Summary Table:

| Function | Key Applications | Benefits |

|---|---|---|

| Compositional Analysis | Thermal decomposition of soil, waste, water for pollutant quantification | Precise temperature control, controlled atmosphere for accurate results |

| Material Remediation | Incineration of hazardous waste, sludge treatment | High-throughput processing, reduces toxicity and volume |

Ready to enhance your environmental testing with precision? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on compositional analysis or bulk remediation, we can tailor a solution for you. Contact us today to discuss how our furnaces can optimize your environmental testing processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing