In short, split tube furnaces are commonly used for material testing, chemical vapor deposition (CVD), sintering of ceramics, pyrolysis, and the graphitization of carbon-based materials. These applications leverage the furnace's precise temperature control and, most importantly, its unique ability to open along a hinge, which dramatically simplifies the loading and unloading of samples.

The core value of a split tube furnace is not just its ability to heat materials, but its hinged design that provides direct access to the heating zone. This feature makes it the superior choice for processes involving delicate samples, complex experimental setups, or frequent sample changes.

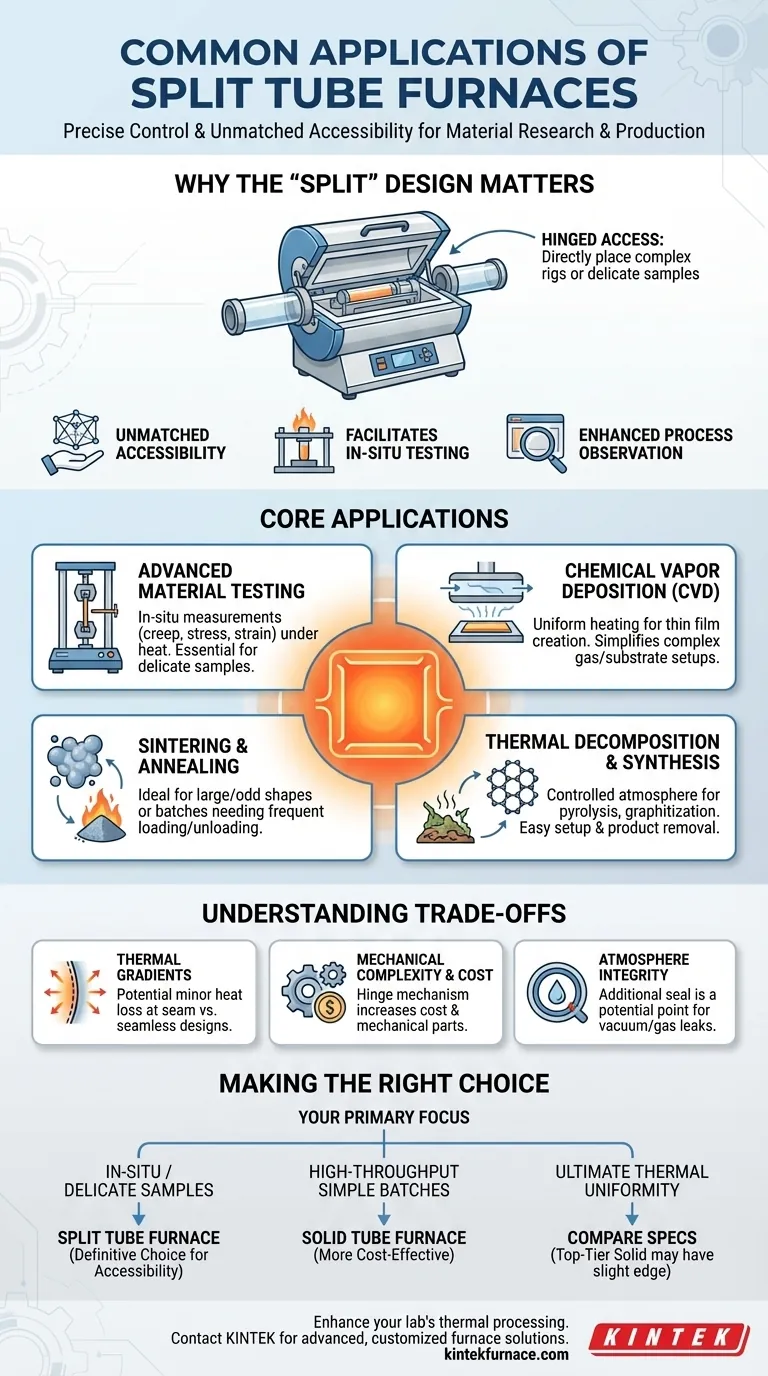

Why the "Split" Design Is a Critical Advantage

A standard tube furnace requires you to slide your sample and process tube into the heated core from one end. A split tube furnace, by contrast, is built in two halves that open on a hinge, allowing you to place the work tube directly into the heating chamber. This simple mechanical difference has profound implications.

Unmatched Sample Accessibility

The hinged body allows you to place samples and process tubes directly into the furnace chamber without disturbing them. This is essential when working with delicate structures, pre-assembled experimental rigs, or samples that cannot be easily slid down a long, narrow tube.

Facilitating In-Situ Testing

The ability to open the furnace and place it around an existing apparatus is its most powerful feature. This makes it the default choice for in-situ material testing, where properties like tensile strength or deformation are measured while the sample is held at a specific high temperature.

Enhanced Process Observation and Speed

Some models offer viewing ports or can be opened quickly (once cooled) to inspect a sample mid-process. While not a primary function, this accessibility is impossible with a solid tube furnace. The design can also allow for slightly faster cooling cycles as the chamber can be opened to vent heat.

Core Applications in Research and Production

The unique advantages of the split-hinge design make these furnaces indispensable for specific, high-value thermal processes in both laboratory and industrial settings.

Advanced Material Testing

This is a primary application where the split design is non-negotiable. It allows the furnace to be closed around a sample already mounted in a tensile tester or other mechanical analysis rig. This enables researchers to study material properties like creep, stress, and strain under precise thermal conditions.

Chemical Vapor Deposition (CVD)

CVD involves flowing reactive gases over a heated substrate to create a thin film. A split tube furnace provides the required uniform heating and controlled atmosphere, while its easy access simplifies the setup of complex quartz tubes, gas inlets, and substrate holders.

Sintering and Annealing

Sintering (fusing powders into a solid mass) and annealing (altering a material's microstructure with heat) require precise temperature control and uniformity. While a solid tube furnace can also perform these tasks, a split tube furnace is preferred when samples are large, oddly shaped, or processed in batches that require frequent loading and unloading.

Thermal Decomposition and Synthesis

Processes like pyrolysis (decomposing organic material with heat in an inert atmosphere) and graphitization (converting carbon precursors into graphite) benefit from the sealed, controlled environment of a tube furnace. The split design again adds a layer of convenience for setting up the reactor and removing the resulting product.

Understanding the Trade-offs

While powerful, a split tube furnace is not always the best choice. Its design introduces specific trade-offs that must be considered.

Potential for Thermal Gradients

While modern designs are excellent, the seam where the two halves of the furnace meet can be a source of minor heat loss. For applications demanding the absolute highest level of thermal uniformity across the entire tube length, a high-end solid tube furnace may have a slight edge.

Mechanical Complexity and Cost

The hinge mechanism, clamps, and seals add mechanical complexity and manufacturing cost. A split tube furnace is typically more expensive than a solid tube furnace of a comparable size and temperature range.

Atmosphere Integrity

The seal between the two halves is a critical component, especially for high-vacuum or ultra-pure gas applications. While robust in high-quality furnaces, it represents an additional potential failure point for leaks compared to the seamless design of a solid tube furnace.

Making the Right Choice for Your Goal

Selecting the correct furnace depends entirely on your process priorities.

- If your primary focus is in-situ analysis or handling delicate samples: The split tube furnace is the definitive choice, as its accessibility is a core requirement.

- If your primary focus is high-throughput batch processing of simple samples: A solid tube furnace may offer a more cost-effective and mechanically simple solution if easy access is not a critical bottleneck.

- If your primary focus is ultimate thermal uniformity for static processes: Carefully compare the specifications, as a top-tier solid tube furnace might provide slightly better performance than a mid-range split model.

Ultimately, choosing a split tube furnace is a decision to prioritize accessibility and workflow flexibility in your thermal processing.

Summary Table:

| Application | Key Benefit |

|---|---|

| Material Testing | Enables in-situ analysis and handling of delicate samples |

| Chemical Vapor Deposition (CVD) | Simplifies setup with uniform heating and easy access |

| Sintering and Annealing | Ideal for large or oddly shaped samples with frequent changes |

| Pyrolysis and Graphitization | Provides controlled atmosphere and convenient product removal |

Ready to enhance your lab's thermal processing with a split tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, boosting efficiency and accuracy. Contact us today to discuss how our tailored solutions can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis