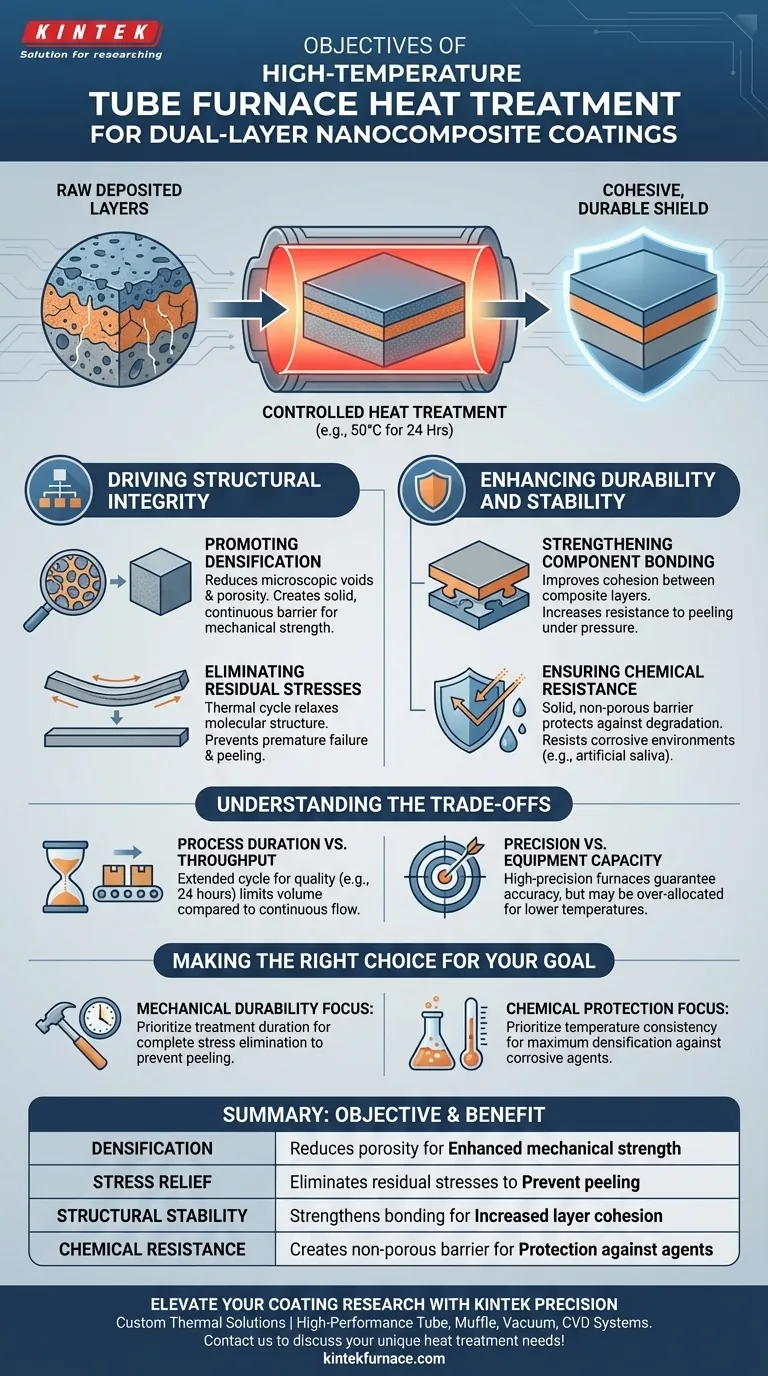

The primary objective of utilizing a high-temperature tube furnace for dual-layer nanocomposite coatings is to create a precisely controlled thermal environment that solidifies the coating's physical structure. By maintaining the samples at a stable temperature—such as 50°C for an extended duration like 24 hours—the process finalizes the material properties initiated during the deposition phase.

The heat treatment serves as a critical stabilization step, transforming the raw deposited layers into a cohesive, durable shield. It fundamentally improves the coating's longevity by resolving internal physical weaknesses and enhancing chemical resistance.

Driving Structural Integrity

Promoting Densification

The deposition process alone often leaves microscopic voids within a coating. Heat treatment facilitates the densification of the nanocomposite material.

This reduction in porosity creates a more solid, continuous barrier, which is essential for the material's mechanical strength.

Eliminating Residual Stresses

Coatings accumulate significant internal stress during the initial deposition onto a substrate.

Without treatment, these stresses can lead to premature failure. The thermal cycle effectively eliminates these residual stresses, allowing the molecular structure to relax into a stable state.

Enhancing Durability and Stability

Strengthening Component Bonding

For dual-layer or composite coatings, the interface between different components is often the weakest point.

The thermal environment enhances the structural stability between these different coating components. This improved cohesion significantly increases the coating's resistance to peeling, ensuring the layers remain intact under mechanical pressure.

Ensuring Chemical Resistance

A well-densified and stress-free coating provides superior protection against environmental factors.

Specifically, this process improves long-term chemical stability, making the coating highly resistant to degradation in corrosive environments, such as those simulating artificial saliva.

Understanding the Trade-offs

Process Duration vs. Throughput

While a tube furnace offers exceptional control, it is inherently a batch process that can be time-consuming.

The primary reference notes a duration of 24 hours to achieve the desired properties at 50°C. This extended cycle time is a necessary investment for quality but limits the volume of parts that can be processed rapidly compared to continuous flow methods.

Precision vs. Equipment Capacity

Tube furnaces are designed for high-precision thermal profiles, often utilized for complex tasks like crystal synthesis or carbonization at much higher temperatures (up to 700°C).

Using such sophisticated equipment for lower-temperature treatments (like 50°C) guarantees accuracy but may represent an over-allocation of resources if simple drying ovens could achieve similar stability for less critical applications.

Making the Right Choice for Your Goal

To optimize your heat treatment process, align your parameters with your specific performance targets:

- If your primary focus is Mechanical Durability: Prioritize the duration of the treatment to ensure complete elimination of residual stresses, which is the key factor in preventing peeling and delamination.

- If your primary focus is Chemical Protection: Focus on the consistency of the temperature control to maximize densification, as a non-porous surface is your best defense against corrosive agents like artificial saliva.

The ultimate value of the tube furnace lies in its ability to deliver the exact thermal stability required to turn a fragile deposit into a permanent, protective surface.

Summary Table:

| Heat Treatment Objective | Benefit to Nanocomposite Coating | Outcome |

|---|---|---|

| Densification | Reduces microscopic voids and porosity | Enhanced mechanical strength |

| Stress Relief | Eliminates residual internal stresses | Prevents peeling and delamination |

| Structural Stability | Strengthens bonding between composite layers | Increased layer cohesion |

| Chemical Resistance | Creates a solid, non-porous barrier | Protection against corrosive agents |

Elevate Your Coating Research with KINTEK Precision

Unlock the full potential of your dual-layer nanocomposites with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Tube, Muffle, Vacuum, and CVD systems designed to deliver the exact thermal stability your materials require. Whether you are optimizing for mechanical durability or chemical resistance, our customizable furnaces ensure uniform heating and precise control.

Ready to transform your material properties? Contact KINTEK today to discuss your unique heat treatment needs with our specialists!

Visual Guide

References

- Noor Waleed Ibrahim, Layla M. Hasan. Corrosion protection of stainless steel by Nanocomposite coating prepared by Pulsed laser ablation in liquid. DOI: 10.21203/rs.3.rs-7263886/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is precise temperature control important in a tubular furnace? Ensure Material Consistency and Quality

- What role does a tube furnace play in the co-pyrolysis of MIPW and COS? Unlock Precise Thermal Waste Transformation

- What is a tube furnace and what are its applications? Unlock Precision Heating for Advanced Materials

- How does a laboratory horizontal tube furnace facilitate the sintering of powder metallurgy structural steel?

- What makes tube furnaces indispensable in academic and industrial settings? Unlock Precision Heating for Advanced Materials

- Why is a tube furnace utilized for long-term heat treatment of FeTeSe crystals? Achieve High Crystallinity & Uniformity

- How does a laboratory tube furnace contribute to the continuity and quality of Mn3O4 arrays? Master Atomic Stitching

- How do you rejuvenate vacuum tubes? A Last-Resort Guide to Salvaging Rare Components