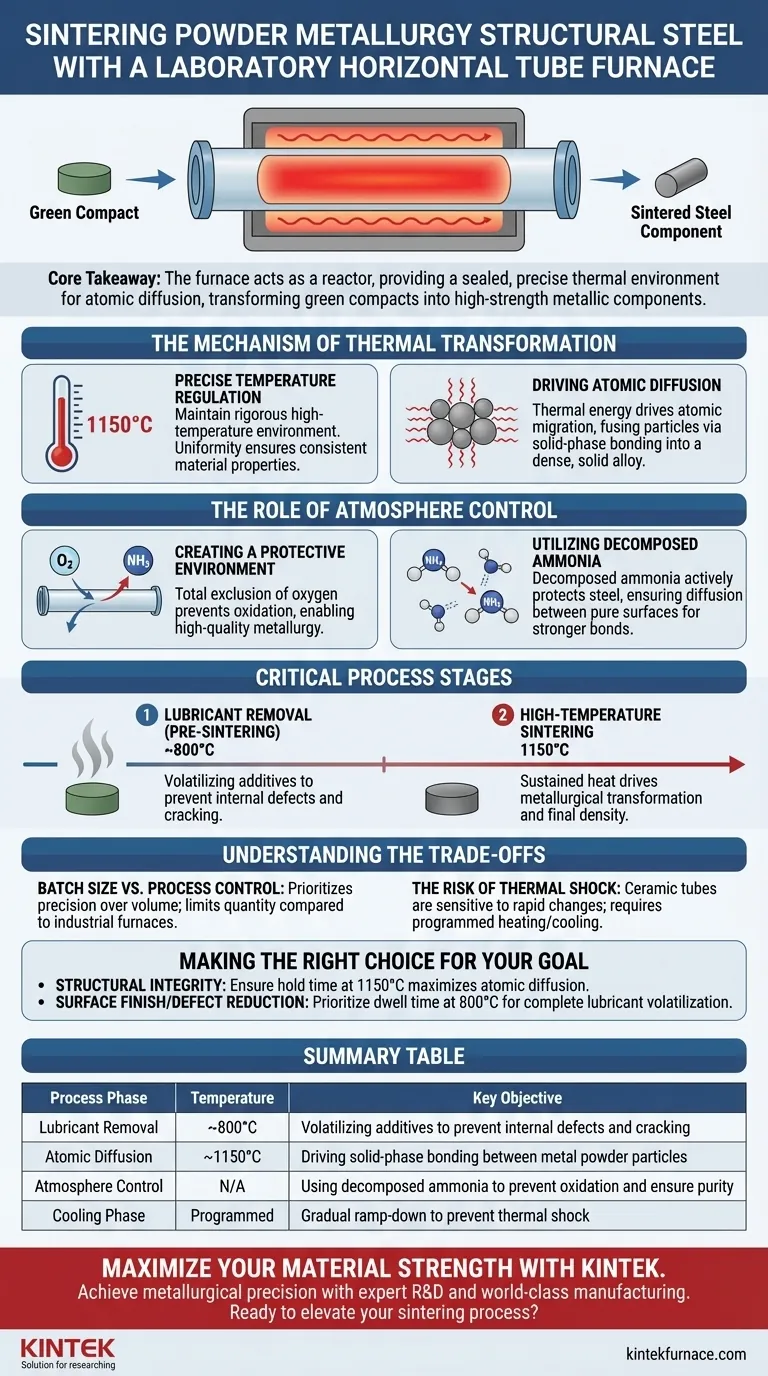

A laboratory horizontal tube furnace facilitates the sintering of powder metallurgy structural steel by providing a sealed, precise thermal environment that drives atomic diffusion. It utilizes controlled heating profiles and protective atmospheres to transform pressed "green" compacts into high-strength metallic components.

Core Takeaway The furnace acts as a reactor that enables solid-phase bonding through atomic migration. Its primary value lies in its ability to maintain a strictly controlled atmosphere (such as decomposed ammonia) while executing multi-stage heating profiles to first remove lubricants and then density the steel at high temperatures.

The Mechanism of Thermal Transformation

Precise Temperature Regulation

For structural steel, the furnace must maintain a rigorous high-temperature environment, typically reaching 1150°C.

The furnace uses specialized heating elements and ceramic tubes to ensure the temperature remains constant across the entire heating zone. This uniformity is essential for consistent material properties throughout the steel component.

Driving Atomic Diffusion

At these elevated temperatures, the furnace supplies the thermal energy required for atomic migration.

This process allows atoms to move across the boundaries of the powder particles. It fuses the particles together through solid-phase bonding, converting the loose structure of the compact into a dense, solid alloy.

The Role of Atmosphere Control

Creating a Protective Environment

Sintering steel requires the total exclusion of oxygen to prevent oxidation, which would degrade the material's strength.

The horizontal tube design allows for a sealed system where air is evacuated or displaced. This creates a "protective atmosphere" essential for high-quality metallurgy.

Utilizing Decomposed Ammonia

According to standard protocols, decomposed ammonia (NH3) is frequently used as the reducing atmosphere in these furnaces.

This gas mixture actively protects the steel surface during the high-heat phase. It ensures that the atomic diffusion process occurs between pure metal surfaces, resulting in stronger bonds.

Critical Process Stages

Stage 1: Lubricant Removal (Pre-Sintering)

Before reaching peak heat, the furnace often facilitates a "burn-off" phase at approximately 800°C.

This stage is critical for volatilizing and removing lubricants or plasticizers used during the initial pressing of the powder. Removing these additives early prevents them from becoming trapped, which causes internal cracking or defects.

Stage 2: High-Temperature Sintering

Once contaminants are removed, the furnace ramps up to the sintering temperature (1150°C).

This is where the actual metallurgical transformation occurs. The sustained heat allows the material to reach its final density and mechanical strength.

Understanding the Trade-offs

Batch Size vs. Process Control

Laboratory tube furnaces prioritize precision over volume.

While they offer exceptional control over temperature profiles and atmosphere purity, their physical size limits the quantity of parts that can be processed simultaneously compared to industrial belt furnaces.

The Risk of Thermal Shock

The ceramic tubes used in these furnaces are sensitive to rapid temperature changes.

Heating and cooling rates must be carefully programmed. Aggressive ramping can damage the furnace tube or cause thermal stress fractures in the steel compacts themselves.

Making the Right Choice for Your Goal

To optimize your sintering process, align your furnace settings with your specific material requirements:

- If your primary focus is structural integrity: Ensure the furnace is programmed for a hold time at 1150°C sufficient to maximize atomic diffusion and density.

- If your primary focus is surface finish and defect reduction: Prioritize a distinct dwell time at 800°C to ensure complete volatilization of all lubricants before higher temperatures are reached.

The success of sintering structural steel relies not just on heat, but on the precise synchronization of temperature staging and atmospheric protection.

Summary Table:

| Process Phase | Temperature | Key Objective |

|---|---|---|

| Lubricant Removal | ~800°C | Volatilizing additives to prevent internal defects and cracking |

| Atomic Diffusion | ~1150°C | Driving solid-phase bonding between metal powder particles |

| Atmosphere Control | N/A | Using decomposed ammonia to prevent oxidation and ensure purity |

| Cooling Phase | Programmed | Gradual ramp-down to prevent thermal shock to ceramic tubes |

Maximize Your Material Strength with KINTEK

Achieve the metallurgical precision your research demands. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for powder metallurgy and structural steel sintering. Whether you require a standard laboratory tube furnace or a fully customized high-temperature solution, our equipment provides the thermal stability and atmosphere control essential for superior density and strength.

Ready to elevate your sintering process? Contact us today to discuss your unique needs!

Visual Guide

References

- Petko Naydenov. DETERMING THE COMPENSATING ACTION OF COPPER AFTER SINTERING OF POWDER METALLURGICAL STRUCTURAL STEELS. DOI: 10.17770/etr2025vol4.8439

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a two-stage sintering process in a tube furnace contribute to high-performance sodium-ion battery cathodes?

- Why is it necessary to use a tube furnace with an inert atmosphere for the thermal debinding of ceramic green bodies?

- What are the key applications of tube furnaces in materials research and chemistry? Unlock Precise High-Temperature Processing

- What role does a high-temperature tube furnace play in biomass carbon skeletons? Master Structural Integrity.

- How does the uniform thermal field provided by a vertical tube resistance furnace impact phase equilibrium experiments?

- In what ways is a vertical tube furnace flexible and diverse? Unlock Custom Solutions for Your Lab

- How vacuum pumping affects Zr2.5Nb nitriding? Achieve pure ZrN surfaces in high-temp tube furnaces.

- What environmental applications do rotary tube furnaces have? Transform Waste into Value with Advanced Thermal Processing