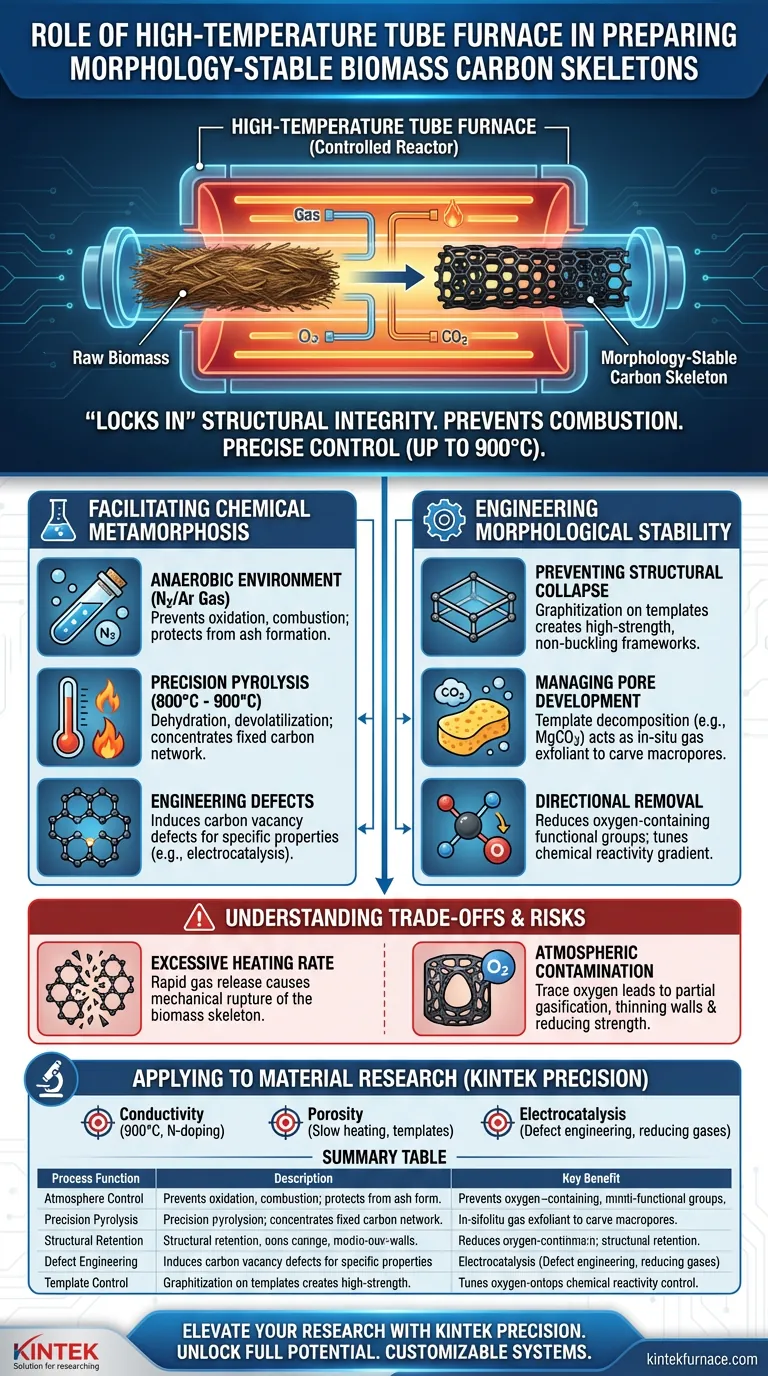

The high-temperature tube furnace is the fundamental tool for "locking in" the structural integrity of biomass during its transition to carbon. It creates a strictly anaerobic or inert environment that prevents the raw material from simply burning away. By precisely regulating heating rates and peak temperatures—often reaching 900°C—the furnace facilitates the complex chemical reactions of dehydration and carbonization while preserving the original physical shape of the biomass.

The tube furnace acts as a controlled reactor that transforms organic fibers into rigid, morphology-stable carbon skeletons. It provides the exact atmospheric and thermal precision required to drive off volatile matter while reinforcing the material’s microscopic pore structure and conductivity.

Facilitating the Chemical Metamorphosis

Maintaining an Anaerobic Environment

A tube furnace provides a sealed, strictly anaerobic or inert gas-protected environment using nitrogen or argon. This atmosphere is critical because it prevents the biomass—such as cotton fibers or fruit peels—from oxidizing or turning into ash. Without this protection, the material would combust rather than transition into a stable carbon framework.

Precision Pyrolysis and Carbonization

The furnace enables high-temperature pyrolysis by maintaining stable environments at specific benchmarks like 800°C to 900°C. During this process, it triggers dehydration and devolatilization, which removes non-carbon elements from the biomass. This concentrates the fixed carbon content, turning soft organic matter into a robust, conductive carbon network.

Engineering Carbon Vacancy Defects

Beyond simple carbonization, the furnace environment can induce critical carbon vacancy defects. These microscopic imperfections are essential for specific applications, such as increasing the electrocatalytic activity of the resulting electrode. This allows researchers to tune the material's performance at a molecular level through thermal manipulation.

Engineering Morphological Stability

Preventing Structural Collapse

Precise temperature control allows the carbon precursor to graphitize on the surface of internal structures or templates. This creates high-strength, thin-layer frameworks that do not buckle under their own weight. By managing the cooling and heating cycles, the furnace ensures the hierarchical pore system remains open and functional rather than collapsing.

Managing Pore Development via Template Decomposition

In advanced preparation, the furnace regulates the decomposition kinetics of template agents like magnesium carbonate. As these templates decompose into CO2, they act as in-situ gas exfoliants that help "carve out" macropores within the skeleton. Simultaneously, the remaining solid particles serve as hard templates that support the formation of micropores and mesopores.

Directional Removal of Functional Groups

By introducing reducing gases like hydrogen mixtures, the tube furnace facilitates the directional removal of oxygen-containing functional groups. This process allows for the gradient adjustment of chemical properties without damaging the delicate physical structure. This level of control is vital for maintaining the "skeleton" while altering its chemical reactivity.

Understanding the Trade-offs

The Risk of Excessive Heating Rates

While high temperatures are necessary, a heating rate that is too aggressive can cause rapid gas release, leading to the mechanical rupture of the biomass skeleton. If the devolatilization happens too quickly, the internal pressure can shatter the very morphology the researcher is trying to preserve.

Atmospheric Purity and Contamination

Even minute traces of oxygen within the furnace tube can lead to partial gasification of the carbon. This thins the skeleton walls and reduces structural stability, potentially leading to a "hollowed-out" material that lacks mechanical strength. Maintaining a high-purity inert flow is an absolute requirement that adds to the operational complexity.

Applying This to Your Material Research

To achieve a stable and functional biomass carbon skeleton, your furnace settings must align with your specific material goals.

- If your primary focus is high electrical conductivity: Use the furnace to reach temperatures near 900°C under nitrogen to maximize graphitization and facilitate nitrogen-doping.

- If your primary focus is high surface area and porosity: Prioritize slow heating rates and the use of in-situ templates to ensure the pore channels do not collapse during devolatilization.

- If your primary focus is electrocatalytic activity: Aim for specific thermal windows that induce carbon vacancy defects while introducing reducing gases to tune surface functional groups.

Mastering the thermal environment of a tube furnace is the definitive step in transforming raw biomass into a high-performance, structurally stable carbon architecture.

Summary Table:

| Process Function | Description & Impact | Key Benefit |

|---|---|---|

| Atmosphere Control | Uses Nitrogen/Argon to maintain an anaerobic environment. | Prevents combustion and oxidation of biomass. |

| Precision Pyrolysis | Stable carbonization at 800°C - 900°C. | Removes volatiles while concentrating fixed carbon. |

| Structural Retention | Regulated heating and cooling cycles. | Prevents hierarchical pore system collapse. |

| Defect Engineering | Induces carbon vacancy defects via thermal manipulation. | Enhances electrocatalytic activity for electrodes. |

| Template Control | Manages decomposition kinetics of templates (e.g., MgCO3). | Creates macropores through in-situ gas exfoliation. |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your biomass carbonization with industry-leading thermal control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of your laboratory. Whether you are engineering morphology-stable skeletons or tuning carbon vacancy defects, our equipment provides the atmospheric purity and thermal stability you need.

Ready to optimize your carbon structures? Contact our experts today to find the perfect customized furnace for your unique research needs!

Visual Guide

References

- Yuan Jia, Yushi Liu. Recent advances in energy storage and applications of form‐stable phase change materials with recyclable skeleton. DOI: 10.1002/cnl2.117

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What precaution should be taken when moving a vacuum tube furnace? Avoid Costly Damage and Safety Risks

- What is a tube furnace and what are its applications? Unlock Precision Heating for Advanced Materials

- What role does a quartz tube furnace play in polyimide pyrolysis? Precision Control for Carbon Molecular Sieves

- Why is high-pressure resistance a critical requirement for SCWG tube reactors? Ensuring Success in Microplastic Energy

- What are the main advantages of using a tube furnace in industrial and laboratory settings? Achieve Precise Temperature and Atmosphere Control

- What are the key heat treatment processes performed in horizontal furnaces? Master Annealing, Hardening, and More

- What are the controlled atmosphere capabilities of a tube furnace? Unlock Precise Gas Control for Your Lab

- What are the space and footprint considerations for vertical and horizontal tube furnaces? Optimize Your Lab Layout