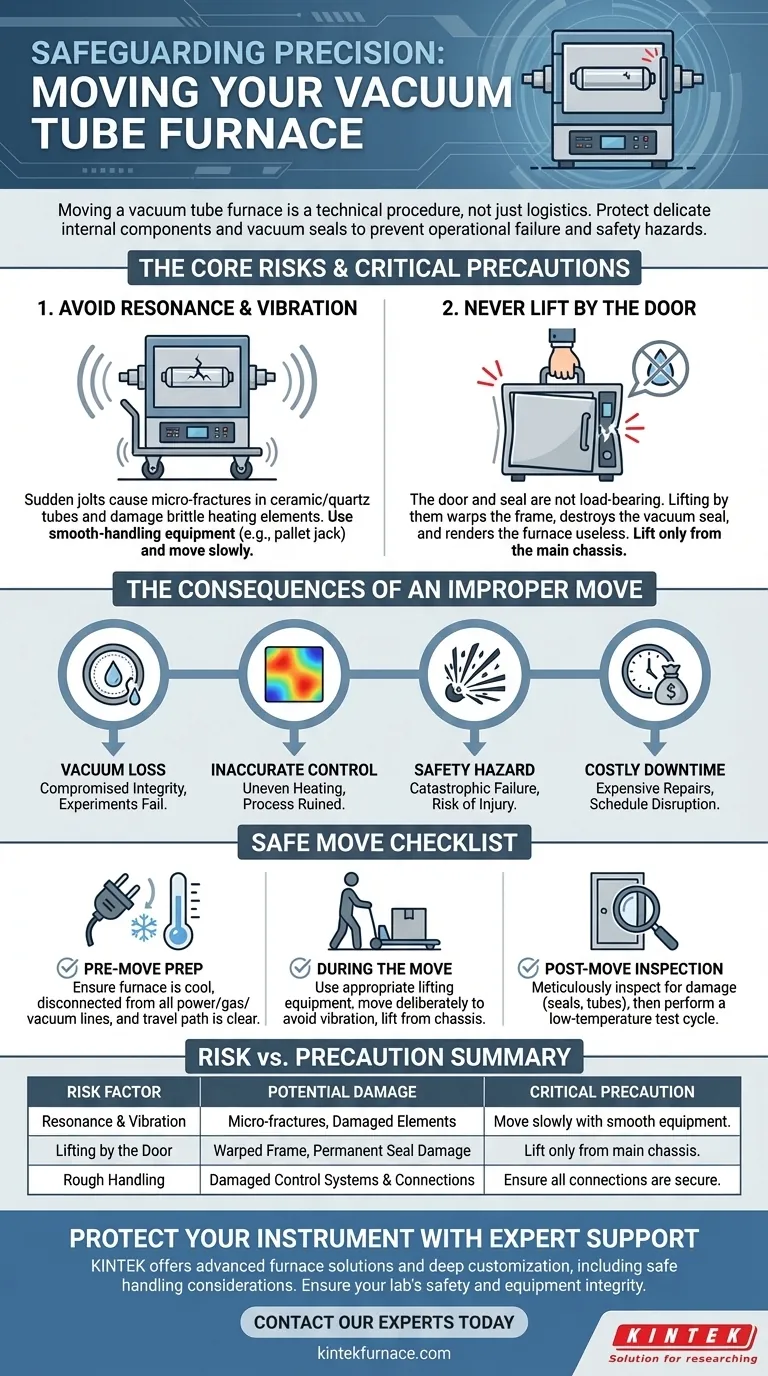

When moving a vacuum tube furnace, the two most critical precautions are to avoid serious resonance or vibration and to never lift the furnace by its door. These actions protect the delicate internal components, such as the heating elements and the vacuum seals, from damage that could compromise the instrument's safety and performance.

Moving a vacuum tube furnace is not just a logistical task; it is a technical procedure. The primary goal is to protect the integrity of the vacuum seals and the alignment of sensitive internal components, as even minor damage during transit can lead to operational failure or a serious safety hazard.

Why a Simple Move Requires Special Care

A vacuum tube furnace is a precision instrument, not just a heavy box. The precautions for moving it are rooted in the sensitivity of its core components, which are designed for high-temperature stability, not for enduring physical shock.

The Risk of Resonance and Vibration

Sudden jolts or sustained vibrations can be destructive. This type of force can cause micro-fractures in the ceramic or quartz process tube, damage brittle heating elements, or misalign critical components within the furnace chamber.

Careful, smooth handling is essential to prevent this. The furnace should be moved slowly, using equipment that minimizes bumps and shocks, such as a pallet jack or a sturdy cart with high-quality casters.

The Door as a Critical Point of Failure

The furnace door and its seal are engineered to create an airtight environment under vacuum. They are not designed to support the furnace's weight.

Lifting the furnace by its door can warp the frame, bend the hinges, and permanently damage the gasket or sealing surface. This will destroy its ability to hold a vacuum, rendering the furnace useless for its intended purpose.

Protecting the Integrated Systems

Modern furnaces contain complex control systems, vacuum gauges, and connections for pumps and gas lines. Rough handling can easily damage these sensitive electronic and mechanical subsystems.

Ensure all connections are secure or disconnected as per the manufacturer's instructions before attempting to move the unit.

The Consequences of an Improper Move

Failing to take proper precautions during a move can lead to significant and expensive problems. Understanding these risks highlights the importance of careful handling.

Compromised Vacuum Integrity

The most common consequence of an improper move is a damaged vacuum seal. Even a small leak can prevent the furnace from reaching the required vacuum level, invalidating experiments and potentially damaging samples.

Inaccurate Temperature and Atmosphere Control

Misalignment of internal components can lead to uneven heating and hot spots within the furnace tube. This destroys the temperature uniformity that is critical for most high-temperature processes.

Serious Safety Hazards

A cracked process tube or a faulty seal can fail catastrophically under high temperature and vacuum. This could result in a sudden loss of containment, exposing operators to extreme heat and potentially hazardous process gases.

Significant Downtime and Repair Costs

Repairing a damaged furnace is often a complex and costly process. Replacing a warped door, broken heating elements, or a cracked tube can lead to extended downtime, disrupting research or production schedules.

A Checklist for Safely Moving Your Furnace

Treat the relocation of your furnace with the same diligence you apply to its operation. Follow this checklist to ensure a safe and successful move.

- If you are preparing for the move: Ensure the furnace is completely cool, disconnected from power, gas, and vacuum lines, and that the travel path is clear of obstructions.

- During the physical move: Use appropriate lifting equipment, move slowly and deliberately to avoid vibration, and always lift from the main chassis or designated structural points—never the door.

- After the move is complete: Meticulously inspect the furnace for any signs of damage, paying close attention to the door seal, process tube, and all external connections before reconnecting and performing a low-temperature test cycle.

By handling your vacuum tube furnace with care and precision during a move, you protect a valuable asset and ensure its continued safe and reliable operation.

Summary Table:

| Risk Factor | Potential Damage | Critical Precaution |

|---|---|---|

| Resonance & Vibration | Micro-fractures in tubes, damaged heating elements, misalignment | Move slowly with smooth-handling equipment (e.g., pallet jack) |

| Lifting by the Door | Warped frame, bent hinges, permanent seal damage | Lift only from the main chassis or designated structural points |

| Rough Handling | Damage to control systems, vacuum gauges, and gas line connections | Ensure all connections are secure/disconnected; clear the travel path |

Protect Your Precision Instrument with Expert Support

Moving a high-value vacuum tube furnace requires precision and care to avoid compromising its performance and safety. At KINTEK, we understand the critical nature of your laboratory equipment.

Leveraging our exceptional R&D and in-house manufacturing capabilities, we provide advanced high-temperature furnace solutions, including robust Tube and Vacuum Furnaces. Our strong deep customization capability ensures your equipment is built to meet unique experimental demands, including considerations for safe handling and installation.

Ensure your furnace's integrity and your lab's safety. Contact our experts today for guidance or to discuss a custom solution tailored to your needs.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents