At its core, a tube furnace is a high-temperature thermal processing device designed for exceptional precision. It consists of a cylindrical chamber, typically made of ceramic, encircled by heating elements that ensure a highly uniform and stable thermal environment for the sample placed inside. This design is fundamental to its use in advanced research and specialized industrial applications.

A tube furnace is not just a high-temperature oven; it is a precision instrument for manipulating materials at the atomic and molecular level. Its primary value lies in providing a perfectly uniform and highly controlled heating environment, often with a specific gas atmosphere or vacuum, that is impossible to achieve with other methods.

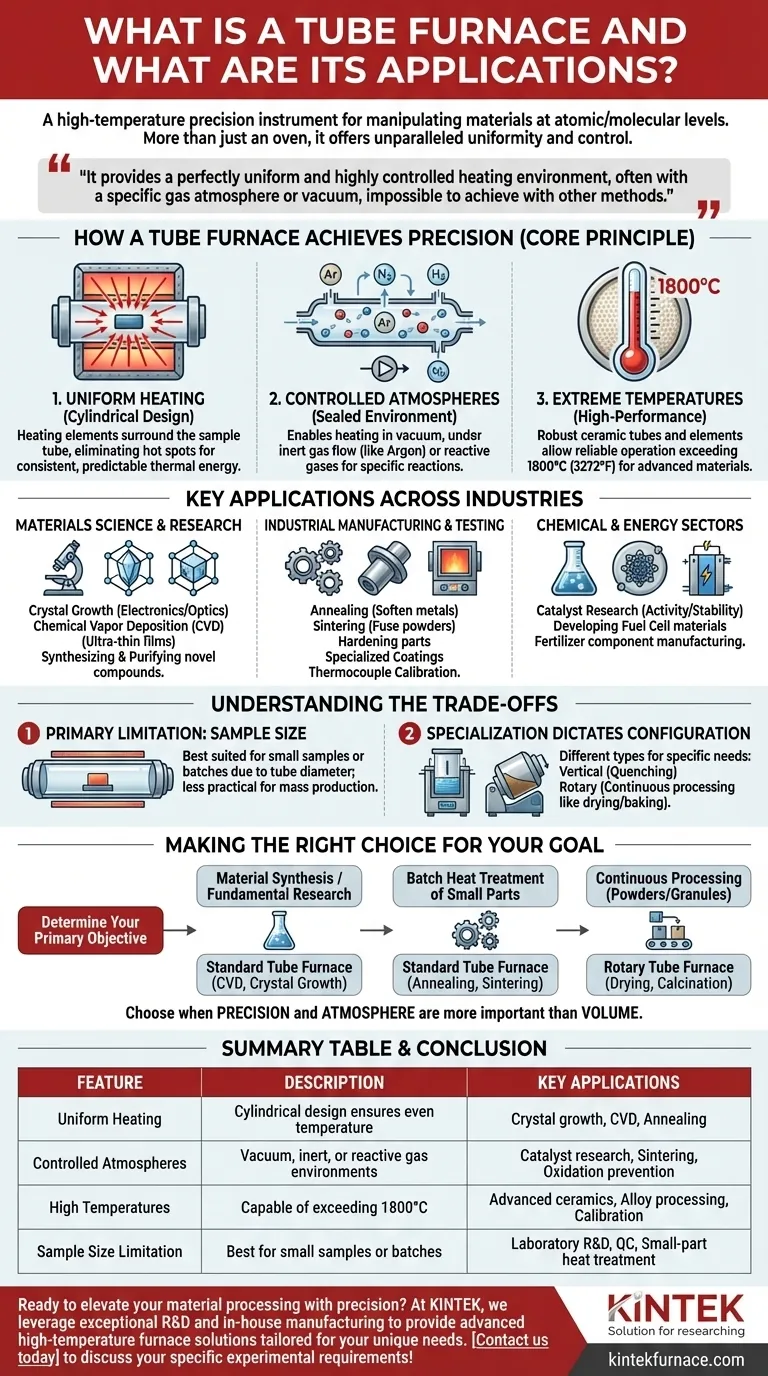

The Core Principle: How a Tube Furnace Achieves Precision

A tube furnace's effectiveness comes from its simple yet powerful design, which masters three key variables: temperature uniformity, atmospheric conditions, and high heat.

The Cylindrical Design for Uniform Heating

The furnace is built around a central tube, which holds the sample. Heating elements surround this tube, radiating heat inward from all directions.

This cylindrical configuration guarantees that the sample receives an exceptionally even and consistent amount of thermal energy, eliminating hot spots and ensuring predictable results.

Achieving Controlled Atmospheres

The enclosed tube is easily sealed, allowing operators to control the internal environment completely. This is a critical feature for many advanced processes.

It enables heating in a vacuum, under a flow of inert gas like argon to prevent oxidation, or with specific reactive gases required for certain chemical reactions.

Reaching Extreme Temperatures

Engineered with robust ceramic tubes and high-performance heating elements, tube furnaces are designed to operate at very high temperatures.

Many models can reliably exceed 1800°C (3272°F), making them suitable for processing advanced ceramics, alloys, and other high-melting-point materials.

Key Applications Across Industries

The unique capabilities of a tube furnace make it an indispensable tool in fields where material properties are paramount.

In Materials Science and Research

Laboratories rely on tube furnaces for foundational research and development. Common uses include crystal growth, creating highly pure single crystals for electronics and optics.

They are also essential for Chemical Vapor Deposition (CVD) to create ultra-thin films on substrates, and for synthesizing and purifying novel inorganic or organic compounds.

In Industrial Manufacturing and Testing

In industrial settings, tube furnaces are used for precise heat treatment of small, high-value components.

This includes processes like annealing to soften metals, sintering to fuse powdered materials into a solid mass, hardening parts, and applying specialized coatings. They are also used for the critical task of thermocouple calibration.

In the Chemical and Energy Sectors

The ability to control both temperature and atmosphere is vital for chemical innovation. Tube furnaces are used for catalyst research, evaluating the activity and stability of new catalytic materials.

They also play a role in developing next-generation energy technologies, such as testing materials for fuel cells or manufacturing key components for fertilizers.

Understanding the Trade-offs

While powerful, a tube furnace is a specialized tool with specific constraints. Understanding its limitations is key to using it effectively.

The Primary Limitation: Sample Size

By design, tube furnaces are best suited for processing small samples or small batches of components. The diameter of the tube inherently limits the physical size of the workpiece.

This makes them ideal for laboratory-scale experiments, quality control, and R&D, but less practical for mass production of large items.

Specialization Dictates Configuration

Not all tube furnaces are the same. A vertical tube furnace, for instance, is often used for quenching tests where a sample must be dropped into a liquid.

A rotary tube furnace tumbles the material during heating, making it suitable for continuous processes like drying or baking powders, as seen in fertilizer production. Choosing the wrong configuration will lead to poor results.

Cost and Operational Complexity

The precision and high-temperature capabilities of a tube furnace come at a cost. They are sophisticated instruments that require knowledge to operate correctly, especially when managing vacuum systems or reactive gas flows.

Making the Right Choice for Your Goal

To determine if a tube furnace is the right solution, consider your primary objective.

- If your primary focus is material synthesis or fundamental research: A standard tube furnace's unparalleled control over temperature and atmosphere is essential for processes like CVD, crystal growth, and creating novel compounds.

- If your primary focus is batch heat treatment of small parts: Its uniform heating is perfect for critical processes like annealing, sintering, or hardening high-value components where consistency is non-negotiable.

- If your primary focus is continuous processing of powders or granules: A rotary tube furnace is specifically designed for applications like drying or calcination where tumbling ensures every particle is treated evenly.

Ultimately, a tube furnace is the definitive choice when precision heating and atmospheric control are more important than sample volume.

Summary Table:

| Feature | Description | Key Applications |

|---|---|---|

| Uniform Heating | Cylindrical design ensures even temperature distribution | Crystal growth, CVD, annealing |

| Controlled Atmospheres | Vacuum, inert, or reactive gas environments | Catalyst research, sintering, oxidation prevention |

| High Temperatures | Capable of exceeding 1800°C for demanding materials | Advanced ceramics, alloy processing, thermocouple calibration |

| Sample Size Limitation | Best for small samples or batches due to tube diameter | Laboratory R&D, quality control, small-part heat treatment |

Ready to elevate your material processing with precision? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your unique needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in materials science, industrial manufacturing, or energy research, we can help you achieve superior results. Contact us today to discuss how our furnaces can meet your specific experimental requirements!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis