The uniform thermal field provided by a vertical tube resistance furnace creates a consistent temperature environment crucial for accurate phase equilibrium data. By utilizing a stable heating zone of 15 to 20 centimeters, this apparatus ensures that samples suspended in the center are heated evenly from all sides. This uniformity eliminates temperature gradients that would otherwise distort experimental results.

In high-temperature experiments, temperature gradients are the enemy of precision. A vertical tube furnace neutralizes this threat by maintaining a uniform thermal field, preventing composition segregation and ensuring valid liquidus temperature measurements.

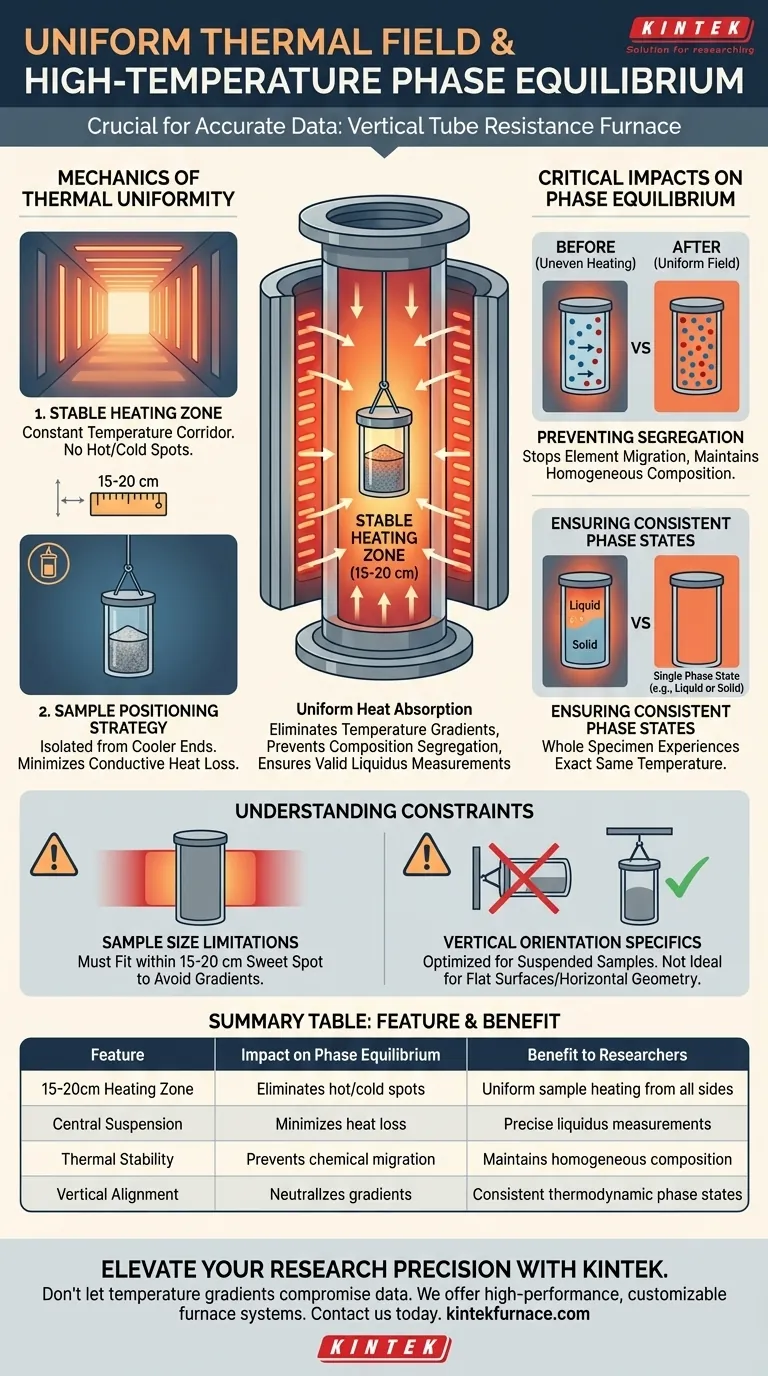

The Mechanics of Thermal Uniformity

The Role of the Heating Zone

To achieve precise data, the furnace generates a specific region of stability. This heating zone typically spans 15 to 20 centimeters in length.

Within this vertical corridor, often powered by lanthanum chromite heating elements, the temperature remains constant. This eliminates the "hot spots" or "cold spots" frequently found in less specialized equipment.

Sample Positioning Strategy

The physical placement of the sample is just as critical as the heat generation.

By suspending the specimen in the exact center of this stable zone, the experimenter isolates it from the cooler ends of the tube. This ensures the sample absorbs thermal energy uniformly, rather than conductively losing heat to a mounting stage.

Critical Impacts on Phase Equilibrium

Preventing Composition Segregation

One of the primary risks in high-temperature equilibrium experiments is the migration of chemical components.

If a sample is heated unevenly, thermal gradients can drive mass transport, causing elements to segregate. A uniform thermal field prevents this migration, ensuring the chemical composition remains homogeneous throughout the experiment.

Ensuring Consistent Phase States

For phase equilibrium, the entire sample must exist in the same thermodynamic state at the same time.

Without a uniform field, one end of a sample could be liquid while the other remains solid. This vertical tube setup guarantees that the whole specimen experiences the exact same temperature, preventing inconsistent phase states.

Understanding the Constraints

Sample Size Limitations

While the 15 to 20-centimeter zone is highly stable, it imposes a strict limit on sample dimensions.

If a sample is too large or elongated, its edges may extend outside this "sweet spot." This would reintroduce the very temperature gradients the furnace is designed to eliminate.

Vertical Orientation Specifics

The vertical design is optimized for suspended samples, which is ideal for equilibrium studies.

However, this orientation may not be suitable for experiments requiring flat liquid surfaces or specific substrate interactions that rely on horizontal geometry.

Making the Right Choice for Your Goal

To maximize the reliability of your high-temperature data, apply these principles:

- If your primary focus is determining liquidus temperatures: Rely on the central suspension method to eliminate thermal gradients that artificially shift melting points.

- If your primary focus is preventing chemical variance: Ensure your sample fits entirely within the 15-20 cm uniform zone to stop composition segregation before it starts.

Precision in phase equilibrium is not just about reaching high temperatures; it is about controlling them completely.

Summary Table:

| Feature | Impact on Phase Equilibrium | Benefit to Researchers |

|---|---|---|

| 15-20cm Heating Zone | Eliminates hot/cold spots within the stable corridor | Ensures uniform sample heating from all sides |

| Central Suspension | Minimizes conductive heat loss to mounting stages | Isolates sample for precise liquidus measurements |

| Thermal Stability | Prevents mass transport and chemical migration | Maintains homogeneous composition throughout |

| Vertical Alignment | Neutralizes temperature gradients along the tube axis | Guarantees consistent thermodynamic phase states |

Elevate Your Research Precision with KINTEK

Don't let temperature gradients compromise your high-temperature phase equilibrium data. At KINTEK, we understand that precision is non-negotiable. Backed by expert R&D and manufacturing, we offer high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all customizable to provide the uniform thermal fields your unique lab needs require.

Ready to eliminate thermal inconsistency? Contact us today to discover how our high-temperature furnaces can ensure the integrity of your experimental results.

Visual Guide

References

- Hamed Abdeyazdan, Evgueni Jak. Phase equilibria in the CuO <sub>0.5</sub> –SbO <sub>1.5</sub> –SiO <sub>2</sub> system. DOI: 10.1111/jace.70123

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the standard and customizable options for tube furnaces? Find the Perfect Fit for Your Lab's Needs

- What are the key advantages of using a rotary tube furnace? Achieve Dynamic, Uniform Heating for Powders

- What role does a high-precision vertical tube furnace play in nickel ore smelting? Master Industrial Smelting Simulation

- How do vacuum tubes work for dummies? The Simple Analogy to Understand Electronic Control

- What are common applications of Tube Furnaces? Unlock Precision in Material Synthesis and Heat Treatment

- What certifications are associated with three-zone split tube furnaces? Key Marks for Quality and Safety

- What is the role of a vacuum tube furnace during the final thermal treatment stage of Fe3O4@CSAC catalysts?

- How do the nitrogen atmosphere and temperature control in a tube furnace affect carbonized lignin fiber quality?