At its core, a vacuum tube is an electronic valve that controls the flow of electricity. It achieves this by heating a metal element inside a glass vacuum tube until it boils off a cloud of electrons. By applying a small voltage to a control grid, you can then manage the movement of these electrons, allowing the tube to act as a powerful amplifier or an incredibly fast switch.

A vacuum tube is fundamentally a device that controls a large flow of electricity using a much smaller electrical signal, all without any moving parts. Its genius lies in using a heated element to create a cloud of electrons and then using a delicate electric field to act as a gatekeeper for that cloud.

The Core Components: An Analogy

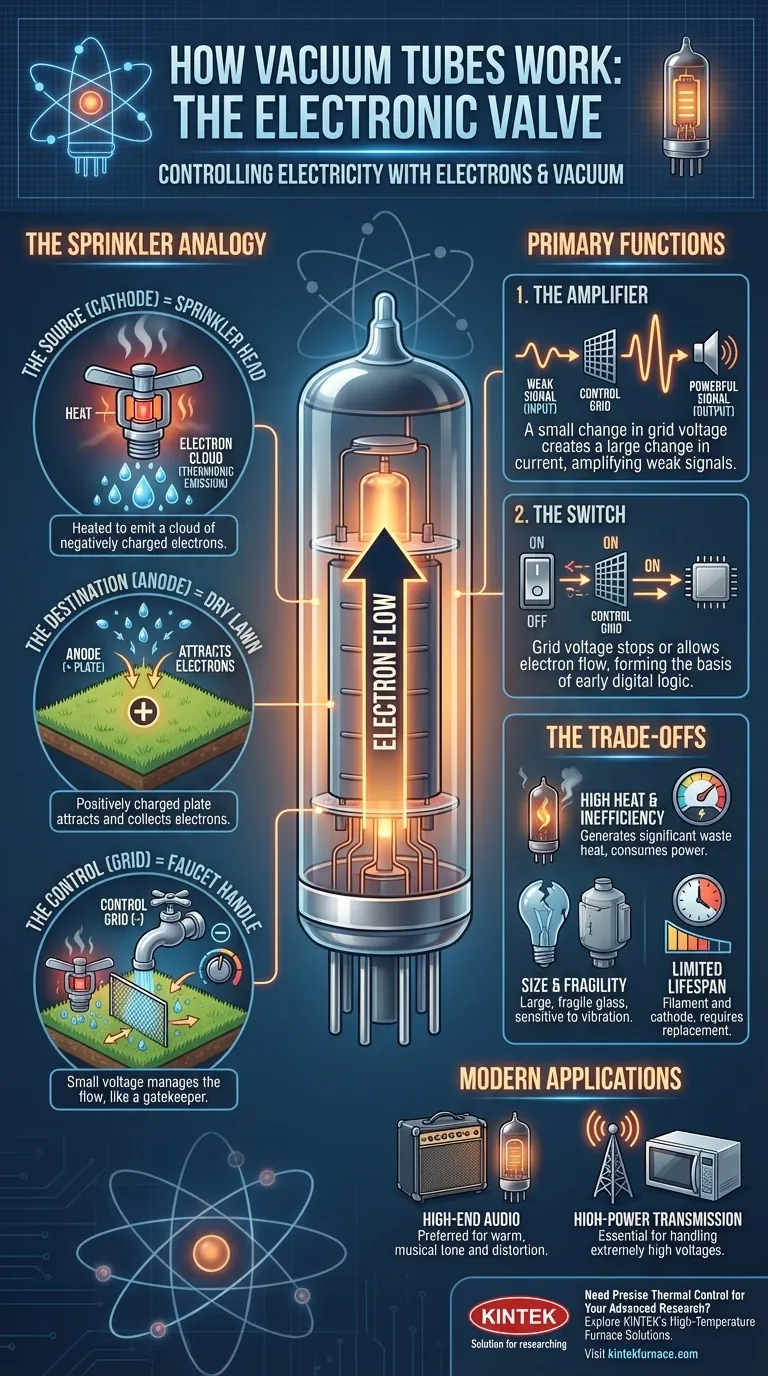

To understand how a vacuum tube works, it's helpful to think of a lawn sprinkler system. You have a source of water, a destination for the water, and a faucet to control the flow. A vacuum tube works on the same principle, but with electrons instead of water.

The Source (Cathode): The Sprinkler Head

Every vacuum tube has a component called a cathode, which is often heated by a glowing filament. Based on a principle called thermionic emission, when the cathode gets hot enough, it emits a cloud of negatively charged electrons.

This is like turning on the main water supply to your sprinkler. The water (electrons) is now available, pooling around the sprinkler head (cathode), ready to go somewhere.

The Destination (Anode): The Dry Lawn

The tube also contains a metal plate called the anode (or simply, the plate). This plate is given a strong positive electrical charge.

Because opposites attract, the positively charged anode acts like a powerful magnet, pulling the negatively charged electron cloud toward it. This is the equivalent of the dry lawn "wanting" the water. The vacuum is critical here; if air were present, its molecules would collide with and block the electrons' path.

The Control (Grid): The Faucet Handle

This is the most important part. Between the electron source (cathode) and its destination (anode), there is a mesh screen called the control grid. This grid acts as the faucet handle.

By applying a small negative voltage to this grid, you can repel the flow of negative electrons, effectively choking off their path to the anode. A more negative charge on the grid closes the valve; a less negative charge opens it up, allowing more electrons to stream through.

How This Control Creates Its Function

The ability to use a tiny voltage on the grid to manage a large flow of electrons from the cathode to the anode is what gives the tube its two primary functions: amplification and switching.

Function 1: The Amplifier

A small change in the grid's voltage causes a very large change in the number of electrons reaching the anode. This is the essence of amplification.

If you feed a weak signal (like the tiny electrical pulse from a guitar pickup) to the control grid, the tube will reproduce that same signal's pattern in the much larger current flowing to the anode. The small input signal has been made powerful enough to drive a speaker.

Function 2: The Switch

You can also use the grid as a simple on/off switch. Applying a sufficiently strong negative voltage to the grid completely stops the flow of electrons, turning the tube "off." Removing that voltage allows the current to flow freely again, turning the tube "on."

Before the invention of the transistor, arrays of vacuum tubes acting as switches formed the basis of the first electronic computers.

Understanding the Trade-offs

While revolutionary, vacuum tubes have significant drawbacks that led to their replacement by solid-state technology in most applications.

The Problem of Heat and Inefficiency

The filament inside a vacuum tube must get very hot to work, generating a tremendous amount of waste heat. This makes them highly inefficient, consuming significant power just to be in a ready state.

The Problem of Size and Fragility

Tubes are made of glass, contain a vacuum, and are physically large. They are fragile, sensitive to vibration, and take up a lot of space compared to a microscopic transistor that can do the same job.

The Problem of Lifespan

Like a lightbulb, the filament in a tube can burn out. Furthermore, the cathode's ability to emit electrons degrades over time, eventually wearing the tube out. They are a consumable component that requires periodic replacement.

When Do Vacuum Tubes Still Matter?

While transistors have replaced tubes in most modern electronics, they remain the superior choice for specific, high-performance applications.

- If your primary focus is high-end audio or guitar amplification: The unique way tubes distort when pushed to their limits creates a "warm" and musically pleasing tone that many artists and audiophiles still prefer.

- If your primary focus is high-power radio or microwave transmission: Tubes can handle extremely high voltages and power levels, making them essential for powerful radio transmitters and microwave ovens.

- If your primary focus is digital logic or consumer electronics: Transistors have almost entirely replaced tubes due to their vastly superior reliability, efficiency, small size, and low cost.

Understanding the vacuum tube is to understand the fundamental principle of electronic control that made all modern technology possible.

Summary Table:

| Component | Analogy | Function |

|---|---|---|

| Cathode | Sprinkler Head | Heated to emit a cloud of electrons (thermionic emission) |

| Anode (Plate) | Dry Lawn | Positively charged to attract and collect electrons |

| Control Grid | Faucet Handle | Uses a small voltage to control the flow of electrons |

| Function | Result | Application |

| Amplifier | Small grid voltage change creates a large current change | Audio amplification, radio signals |

| Switch | Grid voltage turns electron flow on/off | Early computers, logic circuits |

Need Precise Thermal Control for Your Advanced Research?

While vacuum tubes rely on thermionic emission, modern laboratories depend on advanced heating technologies for material synthesis and processing. KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions.

Our product line, including Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you are developing new electronic materials or need reliable thermal processing, we can deliver a solution tailored to your specific needs.

Contact us today to discuss how our heating systems can enhance your research and development!

Visual Guide

Related Products

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the material of the anode in a vacuum tube? Choosing the Right Metal for Power & Performance

- What is the significance of high-precision mass flow controllers in testing NiFe2O4? Ensure Data Integrity

- How do you maintain vacuum pressure? Master the Balance of Gas Load & Pumping Speed

- Why is a high vacuum system critical for sealing the quartz tube used in Fe3GeTe2 single crystal preparation?

- Why is it necessary to achieve a vacuum level of 3 x 10^-2 mm Hg for quartz tube sealing? Ensure Safety and Purity