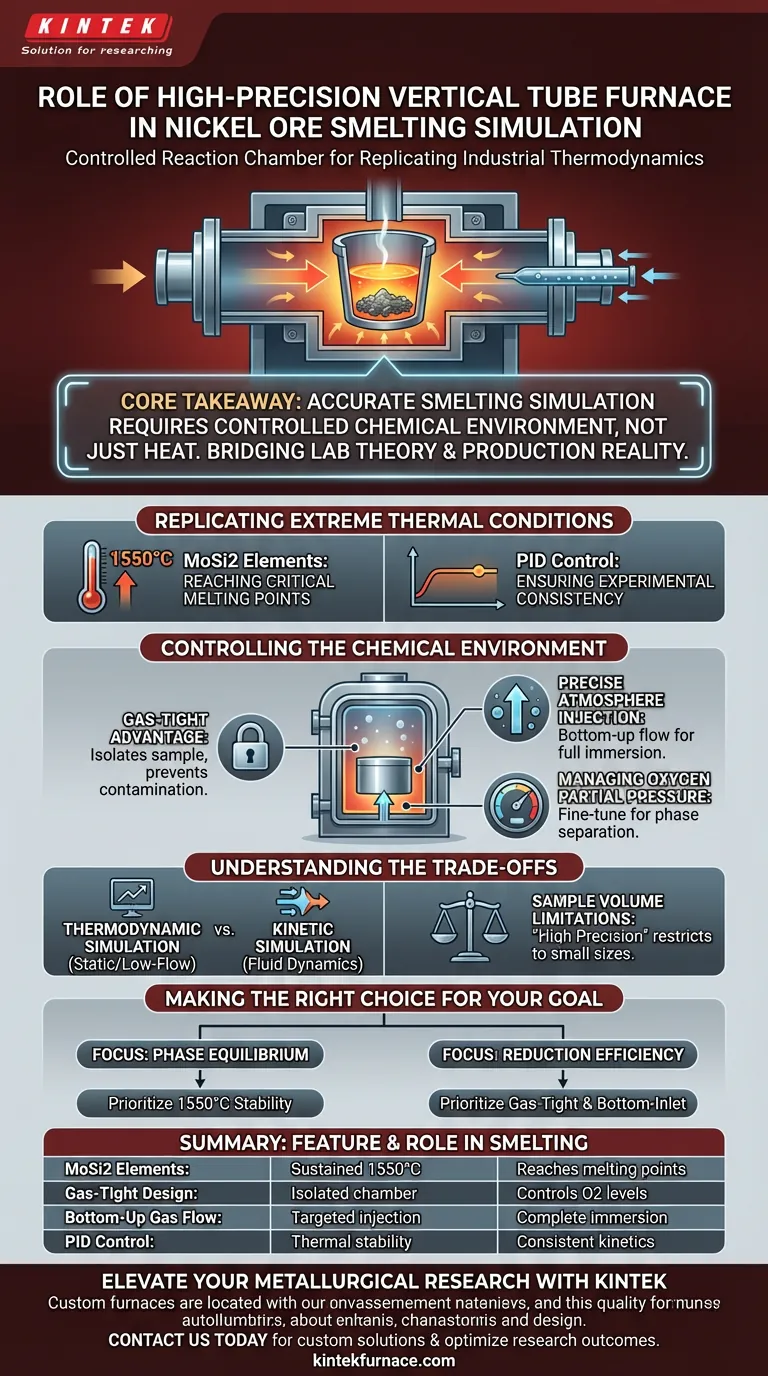

The primary role of a high-precision vertical tube furnace in nickel ore smelting is to act as a strictly controlled reaction chamber that replicates industrial thermodynamics. By utilizing specialized Molybdenum Disilicide (MoSi2) heating elements, this equipment provides the extreme thermal stability required to melt ore samples while simultaneously managing the complex gas atmospheres needed for chemical reduction.

Core Takeaway To simulate industrial smelting accurately, heat alone is insufficient; you must control the chemical environment. This furnace bridges the gap between laboratory theory and production reality by maintaining temperatures up to 1550°C and enabling precise regulation of oxygen partial pressure and reducing atmospheres.

Replicating Extreme Thermal Conditions

To understand the value of this equipment, one must look beyond simple heating. The success of a smelting simulation depends on the stability and intensity of the thermal environment.

Reaching Critical Melting Points

Nickel ore smelting requires temperatures that exceed the capabilities of standard laboratory ovens. The vertical tube furnace uses Molybdenum Disilicide (MoSi2) heating elements to achieve and sustain a high-temperature range of 1550°C.

Ensuring Experimental Consistency

In reliable simulations, temperature fluctuations can ruin data regarding reaction kinetics. This furnace is designed to stably maintain high heat, ensuring that the ore remains in the correct molten phase for the duration of the experiment.

Controlling the Chemical Environment

The most distinct advantage of a high-precision vertical tube furnace is its ability to manipulate the atmosphere surrounding the sample. Smelting is not just melting; it is a chemical reduction process.

The Gas-Tight Advantage

Industrial smelting relies on specific gas mixtures to reduce oxides into metal. This furnace features a gas-tight design that isolates the sample from the ambient lab environment, preventing contamination.

Precise Atmosphere Injection

To simulate the reducing conditions of a blast or electric furnace, gases are introduced through the bottom of the tube. This bottom-up flow ensures the sample is fully immersed in the required gas mixture.

Managing Oxygen Partial Pressure

The separation of nickel from slag is heavily dependent on oxygen partial pressure. This equipment allows researchers to fine-tune this variable, recreating the exact thermodynamic conditions found in large-scale processing.

Understanding the Trade-offs

While this equipment is essential for thermodynamic simulation, it is important to recognize its limitations compared to industrial operations.

Thermodynamic vs. Kinetic Simulation

This furnace excels at simulating thermodynamics (temperature and chemical equilibrium). However, because it is a static or low-flow environment, it may not perfectly replicate the physical fluid dynamics and mass transfer rates of a churning industrial furnace.

Sample Volume Limitations

The "high precision" nature of the equipment generally restricts it to small sample sizes. While this allows for exact control, it means the results must be carefully extrapolated when applying them to bulk processing scenarios.

Making the Right Choice for Your Goal

When designing your experiment, consider which variables are most critical to your data set.

- If your primary focus is Phase Equilibrium: Prioritize the furnace's ability to hold a steady 1550°C, as temperature stability is the deciding factor in phase separation.

- If your primary focus is Reduction Efficiency: Focus on the gas-tight capabilities and bottom-gas inlet systems to strictly control oxygen partial pressure.

By leveraging the high-temperature stability and atmospheric precision of this furnace, you transform a basic heating test into a rigorous simulation of industrial metallurgy.

Summary Table:

| Feature | Role in Smelting Simulation | Benefit |

|---|---|---|

| MoSi2 Elements | Sustained heat up to 1550°C | Reaches critical melting points for nickel ore |

| Gas-Tight Design | Isolated reaction chamber | Prevents contamination and controls oxygen levels |

| Bottom-Up Gas Flow | Targeted atmosphere injection | Ensures complete sample immersion in reducing gases |

| PID Control | Thermal stability and precision | Guarantees consistent reaction kinetics and data |

Elevate Your Metallurgical Research with KINTEK

Precise smelting simulations require more than just heat; they demand absolute control over the thermal and chemical environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces, all fully customizable for your unique mineral processing needs.

Whether you are refining nickel ore or developing new alloys, our equipment provides the 1550°C stability and gas-tight precision necessary to bridge the gap between lab theory and industrial production. Contact us today to discuss your custom furnace requirements and optimize your research outcomes!

Visual Guide

References

- Erdenebold Urtnasan, Jei‐Pil Wang. Artificial Slags with Modulated Properties for Controlled Nickel Dissolution in Smelting Process. DOI: 10.1007/s12666-024-03304-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a stable nitrogen flow required in a tube furnace for hydrochar carbonization? Ensure High-Carbon Purity

- What are the possible configurations of heated sections in a High Temperature Tube Furnace? Choose the Right Setup for Your Process

- What are the process advantages of using a horizontal tube pyrolysis reactor? Maximize Precision and Data Integrity

- How does a high-temperature tube reactor system simulate industrial environments for evaluating catalyst performance?

- How is the structure of a fluidized bed vertical tube furnace designed? Unlock Efficient Heat Transfer and Reaction Control

- What are the typical applications for tube furnaces? Master Precise Thermal Processing

- What is the function of a tube furnace and nitrogen flow in biomass carbonization? Unlock Superior Bio-Carbon Quality

- What is the role of high-temperature calcination in a tube furnace for H-Beta zeolite? Engineer Precision Catalysts