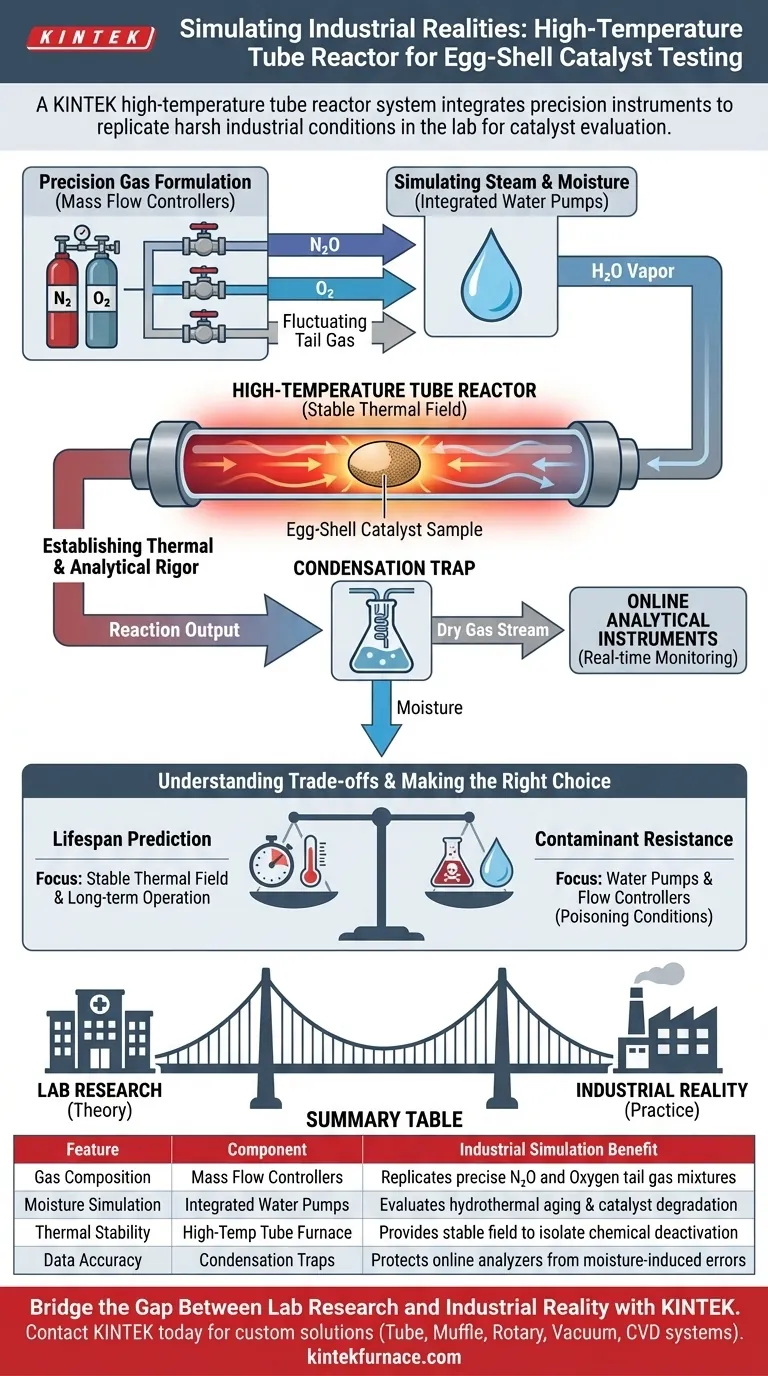

A high-temperature tube reactor system serves as a precision simulator for industrial operating conditions by integrating high-precision mass flow controllers with dedicated water pumps. This hardware combination synthesizes complex tail gas environments—specifically mixtures of oxygen, water vapor, and nitrous oxide (N2O)—to replicate the harsh realities of industrial processing within a controlled laboratory setting.

The core value of this system lies in its ability to decouple variables; it provides a stable thermal field alongside precise chemical inputs to rigorously test catalyst longevity and resistance to poisoning before full-scale deployment.

Recreating the Chemical Environment

To evaluate an egg-shell catalyst effectively, you must move beyond simple air-flow tests and replicate the "dirty" air of a factory.

Precision Gas Formulation

The system utilizes high-precision mass flow controllers to dictate the exact composition of the gas stream.

This allows researchers to introduce specific concentrations of N2O and oxygen, mimicking the fluctuating tail gas found in industrial output.

Simulating Steam and Moisture

Industrial environments rarely consist of dry gas; they often contain significant water vapor which can accelerate catalyst degradation.

Integrated water pumps inject precise amounts of moisture into the system, ensuring the test environment accounts for the hydrothermal aging effects common in real-world operations.

Establishing Thermal and Analytical Rigor

Simulating the gas mixture is only half the battle; the physical conditions of the reactor must also remain constant to yield usable data.

The Stable Thermal Field

The tube reactor is designed to maintain a stable thermal field throughout the testing duration.

This stability is critical for distinguishing between thermal degradation of the catalyst and chemical deactivation caused by the gas mixture.

Protecting Analytical Integrity

To measure performance, the system employs online analytical instruments that monitor reaction outputs in real-time.

However, because the simulation uses water vapor, condensation traps are essential to remove moisture before the gas reaches the analyzers, ensuring the data remains accurate and the equipment undamaged.

Understanding the Trade-offs

While this system provides a high-fidelity simulation, it is important to recognize the inherent challenges in high-temperature testing.

Complexity of "Wet" Simulations

Introducing water vapor via pumps adds a layer of complexity compared to dry testing.

You must rely on the condensation traps functioning perfectly; if they fail, moisture can enter the online analyzers, leading to erratic data or equipment failure.

The Scope of Simulation

The system excels at simulating chemical composition and temperature, specifically for tail gas environments containing N2O.

However, it is a specialized tool; its accuracy is defined by the precision of the flow controllers and the stability of the heating element. Any drift in these components directly impacts the validity of the "industrial" simulation.

Making the Right Choice for Your Goal

When designing your evaluation protocol, consider which variable matters most to your specific industrial application.

- If your primary focus is Lifespan Prediction: Rely on the stable thermal field and long-term operation capabilities to identify thermal degradation over extended periods.

- If your primary focus is Contaminant Resistance: Utilize the water pumps and flow controllers to create "poisoning conditions," stressing the catalyst with high moisture and N2O loads.

Ultimately, this system bridges the gap between theory and practice by subjecting catalysts to the exact thermal and chemical stresses they will face in the field.

Summary Table:

| Feature | Component | Industrial Simulation Benefit |

|---|---|---|

| Gas Composition | Mass Flow Controllers | Replicates precise N2O and Oxygen tail gas mixtures |

| Moisture Simulation | Integrated Water Pumps | Evaluates hydrothermal aging and catalyst degradation |

| Thermal Stability | High-Temp Tube Furnace | Provides a stable field to isolate chemical deactivation |

| Data Accuracy | Condensation Traps | Protects online analyzers from moisture-induced errors |

Bridge the Gap Between Lab Research and Industrial Reality

Don't let unpredictable industrial variables compromise your research. At KINTEK, we understand that evaluating catalyst longevity requires a perfect balance of thermal stability and precise chemical control. Backed by expert R&D and manufacturing, KINTEK offers Tube, Muffle, Rotary, Vacuum, and CVD systems, all fully customizable to simulate the exact thermal and chemical stresses of your field environment.

Whether you are predicting catalyst lifespan or testing contaminant resistance, our high-temperature laboratory furnaces provide the precision you need. Contact KINTEK today to discuss your custom reactor needs and ensure your materials are ready for full-scale deployment.

Visual Guide

References

- Eun-Han Lee, Shin‐Kun Ryi. Quick drying process: a promising strategy for preparing an egg-shell-type Cu/γ-Al <sub>2</sub> O <sub>3</sub> catalyst for direct N <sub>2</sub> O decomposition. DOI: 10.1039/d4ta07764d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a stable nitrogen flow required in a tube furnace for hydrochar carbonization? Ensure High-Carbon Purity

- Why Use a Programmable Tube Furnace for Ni-WOx/SAPO-11 Calcination? Ensure Catalyst Purity & Performance

- What critical environmental conditions does a high-temperature tube furnace provide? Optimize CPOF-4/5 Cross-Linking

- What is the function of a tube furnace during the CVD growth of WS2 monolayers? Expert Thermal Control Guide

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What is the role of a vacuum tube furnace during the final thermal treatment stage of Fe3O4@CSAC catalysts?

- What industries commonly use horizontal furnaces? Unlock High-Temperature Processing for Your Sector

- What is the role of horizontal furnaces in battery manufacturing? Achieve Precision Thermal Processing for Superior Battery Performance