The primary function of a tube furnace in this context is to create a precisely controlled high-temperature thermal field. This environment is essential for sublimating solid precursors (typically sulfur powder and a tungsten source) and driving the chemical reaction required to synthesize Tungsten Disulfide (WS2) monolayers.

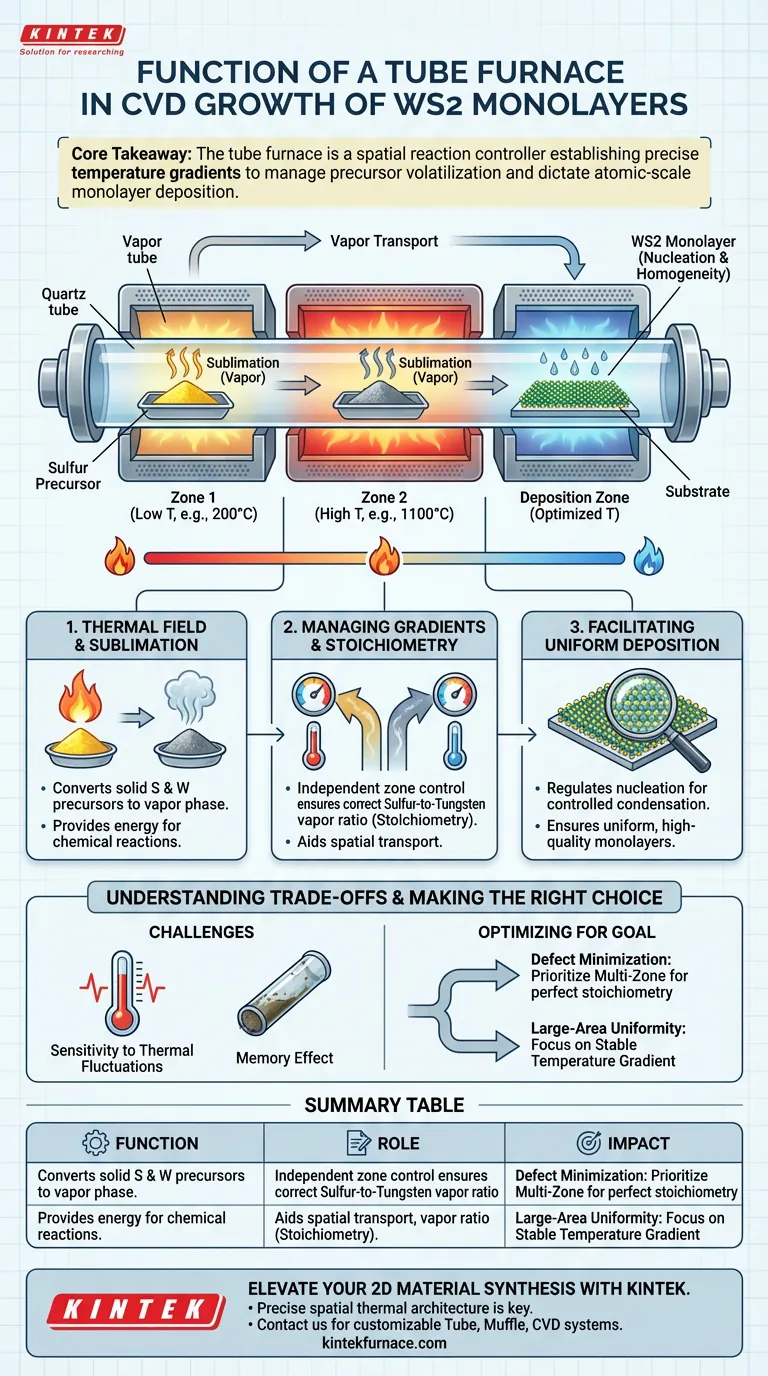

Core Takeaway The tube furnace is not merely a heating element; it is a spatial reaction controller. By establishing specific temperature gradients, it manages the distinct volatilization rates of different precursors and dictates exactly where and how they deposit onto the substrate to form atomic-scale monolayers.

The Role of the Thermal Field

The fundamental purpose of the tube furnace is to provide the energy required to change the state of materials.

Sublimation of Precursors

Solid precursors, such as sulfur and tungsten sources, must be converted into a vapor phase. The furnace provides the high thermal energy needed to sublimate these powders within the center zone.

Driving Chemical Reactions

Once in the vapor phase, the precursors must react chemically to form WS2. The furnace maintains the high temperatures necessary to overcome the activation energy barrier for this reaction, ensuring the formation of the desired compound.

Managing Temperature Gradients

The most sophisticated function of the tube furnace is the creation of a "thermal slope" or gradient. This is critical because the precursors have vastly different physical properties.

Independent Zone Control

Effective growth often requires a multi-zone setup. For example, sulfur evaporates at relatively low temperatures (approx. 200°C), while tungsten sources (like WO3) require much higher temperatures (approx. 1100°C) to become reactive.

Controlling Stoichiometry

By maintaining these distinct thermal zones, the furnace ensures the correct ratio of sulfur to tungsten vapor. This balance, known as stoichiometry, is vital; without it, the material may suffer from high defect rates or fail to form a continuous monolayer.

Spatial Transport

The temperature gradient aids in the transport of vapors. It helps move the sublimated materials from the high-temperature source zones downstream to the slightly cooler deposition zone, where the substrate resides.

Facilitating Uniform Deposition

The ultimate goal of the CVD process is the creation of a high-quality, atomic-thickness film.

Regulating Nucleation

The furnace design ensures that the temperature at the substrate is optimized for controlled condensation. This allows the vapor to settle and arrange itself into a crystalline lattice, a process called nucleation.

Ensuring Homogeneity

A stable thermal environment prevents fluctuations that could lead to uneven layers. The furnace ensures that the precursor vapor is deposited uniformly across the substrate, resulting in high-quality monolayers rather than thick, bulk crystals.

Understanding the Trade-offs

While the tube furnace is the standard tool for this process, it introduces specific challenges that must be managed.

Sensitivity to Thermal Fluctuations

Even minor deviations in the temperature profile can alter the vapor pressure of the precursors. This can drastically change the vapor concentration, leading to inconsistent film thickness or incomplete coverage.

The "Memory Effect"

Tube furnaces can retain residues from previous experiments on the quartz tube walls. At high temperatures, these contaminants can vaporize and incorporate into the new WS2 monolayer, degrading its electronic properties.

Making the Right Choice for Your Goal

Depending on your specific research or production objectives, you should prioritize different aspects of furnace operation.

- If your primary focus is Defect Minimization: Prioritize a multi-zone furnace that allows you to decouple the evaporation temperatures of Sulfur and Tungsten to ensure perfect stoichiometry.

- If your primary focus is Large-Area Uniformity: Focus on the stability of the temperature gradient in the deposition zone to ensure the vapor condenses evenly across the entire substrate surface.

Success in growing WS2 monolayers depends not just on reaching high temperatures, but on the precise spatial architecture of that heat.

Summary Table:

| Function | Role in WS2 Growth | Impact on Material |

|---|---|---|

| Sublimation | Converts solid S and WO3 precursors into vapor | Ensures precursor availability |

| Thermal Gradient | Manages distinct volatilization rates of S vs. W | Controls stoichiometry and purity |

| Kinetic Energy | Provides energy to overcome activation barriers | Drives chemical reaction |

| Nucleation | Regulates deposition rate on the substrate | Achieves atomic-scale homogeneity |

Elevate Your 2D Material Synthesis with KINTEK

Precise spatial thermal architecture is the difference between bulk crystals and high-quality WS2 monolayers. At KINTEK, we provide the specialized equipment needed to master these gradients. Backed by expert R&D and manufacturing, we offer high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory needs.

Ready to optimize your thin-film deposition?

Contact KINTEK today for a customized furnace solution

Visual Guide

References

- Jun Zhou, Junpeng Lü. Phase-engineered synthesis of atomically thin te single crystals with high on-state currents. DOI: 10.1038/s41467-024-45940-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What environmental protection applications utilize multi zone tube furnaces? Unlock Precision in Waste Treatment and Green Tech

- What is the function of the vacuum-sealed quartz tube in CVT? Essential Role in 1T-TaS2 Crystal Growth

- How do the nitrogen atmosphere and temperature control in a tube furnace affect carbonized lignin fiber quality?

- What are the advantages of horizontal tube furnaces? Achieve Superior Thermal Uniformity and Flexibility

- What types of atmospheres can a horizontal electric furnace control? Master Material Processing with Precision

- What is the significance of defining the quartz tube as a heat transfer boundary? Optimize Your Furnace Modeling

- What is a lab tube furnace? The Ultimate Guide to Precision High-Temp Processing

- How is a laboratory tube furnace utilized in the thermal shock reduction process to produce RGO?