At their core, horizontal tube furnaces offer three primary advantages: exceptional thermal uniformity, flexibility for larger or multiple samples, and straightforward integration with controlled atmosphere systems. Their design, where heating elements surround the processing tube, makes them a standard for achieving consistent, repeatable results in a wide range of laboratory and production environments.

The decision between furnace orientations is less about which is "better" and more about which is optimal for a specific task. Horizontal tube furnaces are the definitive choice for applications prioritizing uniform radial heating across larger samples and for streamlined batch processing workflows.

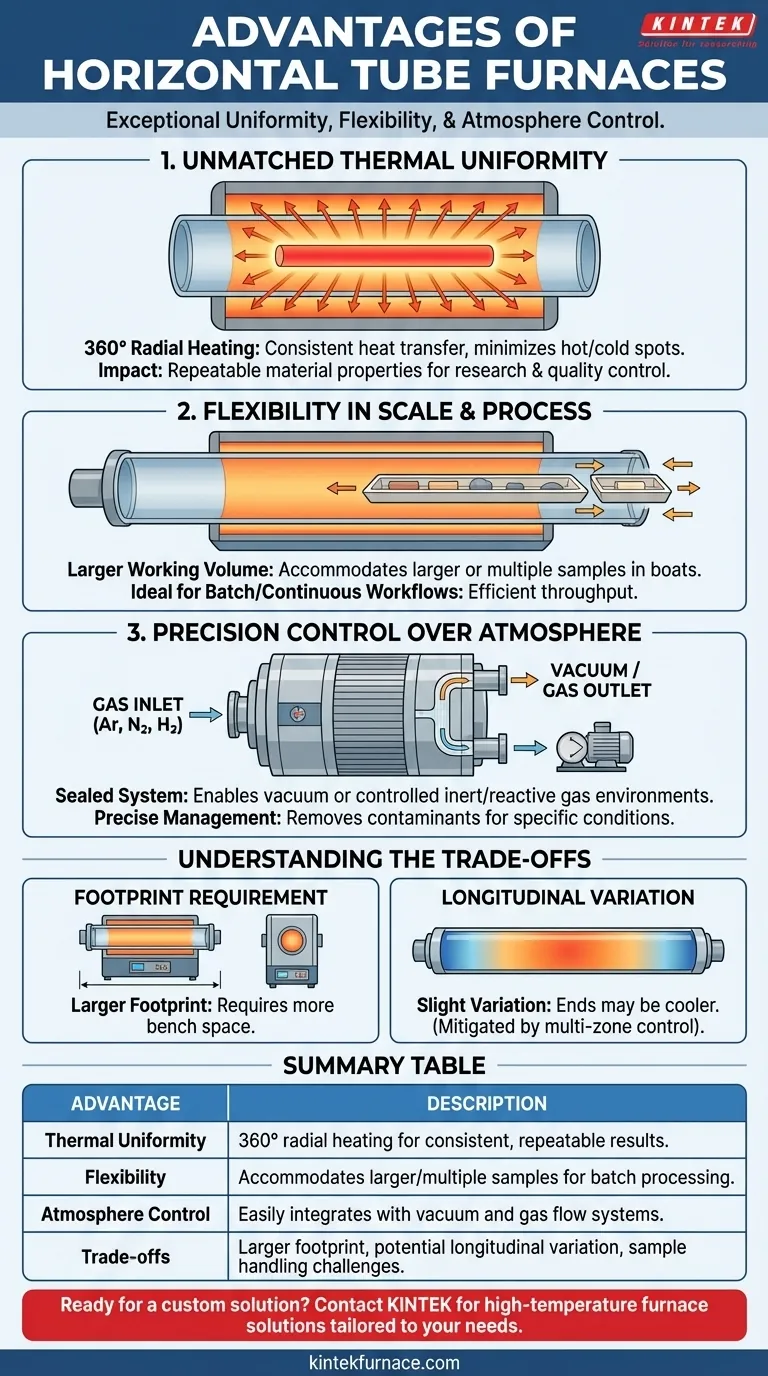

The Foundation: Unmatched Thermal Uniformity

The most significant advantage of a horizontal tube furnace is its ability to deliver exceptionally uniform heat to a sample. This is a direct result of its fundamental design.

How Horizontal Design Achieves Uniformity

The sample rests inside a horizontal tube that is typically surrounded on all sides by heating elements. This 360-degree exposure ensures heat is transferred efficiently and evenly to the entire circumference of the sample.

This radial consistency minimizes hot or cold spots on the material's surface, which is critical for processes like annealing or crystal growth where thermal gradients can ruin outcomes.

The Impact on Material Consistency

Because every part of the sample along its cross-section experiences the same temperature, the resulting material properties are more consistent and repeatable.

This uniformity is crucial for research and quality control, ensuring that variations in results come from experimental parameters, not from inconsistent heating within the furnace itself.

Flexibility in Scale and Process

Beyond thermal performance, the horizontal orientation provides practical advantages for sample handling and process design.

Accommodating Larger or Multiple Samples

Horizontal furnaces generally offer a larger effective working volume compared to their vertical counterparts. This allows for the processing of physically larger components or, more commonly, multiple smaller samples placed in a "boat" or tray.

This capability makes them highly efficient for batch production where throughput is a key consideration.

Ideal for Batch and Continuous Workflows

The design is inherently flexible for sample loading and unloading. Materials can be easily slid in and out, making it suitable for both single-batch operations and semi-continuous processes where material is pushed through the heated zone.

Precision Control Over the Processing Environment

Modern material processing rarely happens in ambient air. Horizontal furnaces are easily adapted to create highly specific atmospheric conditions.

Managing Atmosphere: From Vacuum to Reactive Gases

The simple, linear tube is easy to seal on both ends. This allows for the integration of vacuum systems to remove oxygen or other contaminants before heating.

Furthermore, ports can be added to introduce a flow of inert gas (like argon or nitrogen) or reducing gases to create a specific, non-oxidizing environment. Precise mass flow controllers can manage these gas mixtures for highly repeatable conditions.

Understanding the Trade-offs

No design is perfect for every application. To make an informed decision, you must be aware of the inherent compromises of the horizontal configuration.

The Footprint Requirement

By their nature, horizontal furnaces have a larger physical footprint. They require more bench or floor space than a vertical furnace of a comparable volume, which can be a constraint in crowded labs.

The Nuance of "Uniformity": Radial vs. Longitudinal

While radial uniformity (around the tube's circumference) is excellent, longitudinal uniformity (along the length of the tube) can have slight variations. The ends of the furnace will naturally be cooler than the center.

This is often mitigated by using multi-zone furnaces with independent controllers for different sections, allowing you to create a flat temperature profile across a longer length.

Challenges in Sample Handling

While loading is flexible, it can be more challenging to precisely position samples compared to a vertical furnace, where gravity can be an advantage. Powders or melts, for instance, must be contained in a boat and cannot be dropped or held in a crucible as easily as in a vertical setup.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your processing goals and material constraints.

- If your primary focus is process repeatability for solid samples: The superior radial thermal uniformity of a horizontal furnace is its most compelling advantage.

- If your primary focus is high-throughput batch processing: The larger volume and ease of loading for multiple samples make it a highly efficient choice.

- If your primary focus is process flexibility with controlled atmospheres: The simple tube design is easily adaptable for vacuum or gas flow systems.

- If your primary focus is working with powders, melts, or minimizing footprint: Carefully consider the sample handling challenges and space requirements, as a vertical furnace may be more suitable.

By understanding these core principles and trade-offs, you can confidently select the furnace configuration that best aligns with your material processing goals.

Summary Table:

| Advantage | Description |

|---|---|

| Thermal Uniformity | Provides 360-degree radial heating for consistent, repeatable results in processes like annealing and crystal growth. |

| Flexibility | Accommodates larger or multiple samples, ideal for batch processing and high-throughput workflows. |

| Atmosphere Control | Easily integrates with vacuum and gas flow systems for precise environmental management. |

| Trade-offs | Larger footprint, potential longitudinal temperature variations, and sample handling challenges for powders or melts. |

Ready to enhance your lab's efficiency with a custom horizontal tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can help you achieve superior thermal processing results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision