At its core, a fluidized bed vertical tube furnace is designed around a central vertical chamber containing a bundle of vertically oriented tubes. Gas is forced upwards from the bottom of this chamber, flowing through and around the tubes. This upward flow is precisely controlled to lift and suspend solid particles (like fuel or a catalyst), causing them to behave like a boiling liquid—a state known as a fluidized bed.

The vertical structure is not merely a design choice; it is the fundamental requirement for enabling fluidization. This orientation uses gravity and upward gas flow to suspend solid particles, creating an exceptionally efficient environment for heat transfer and chemical reactions.

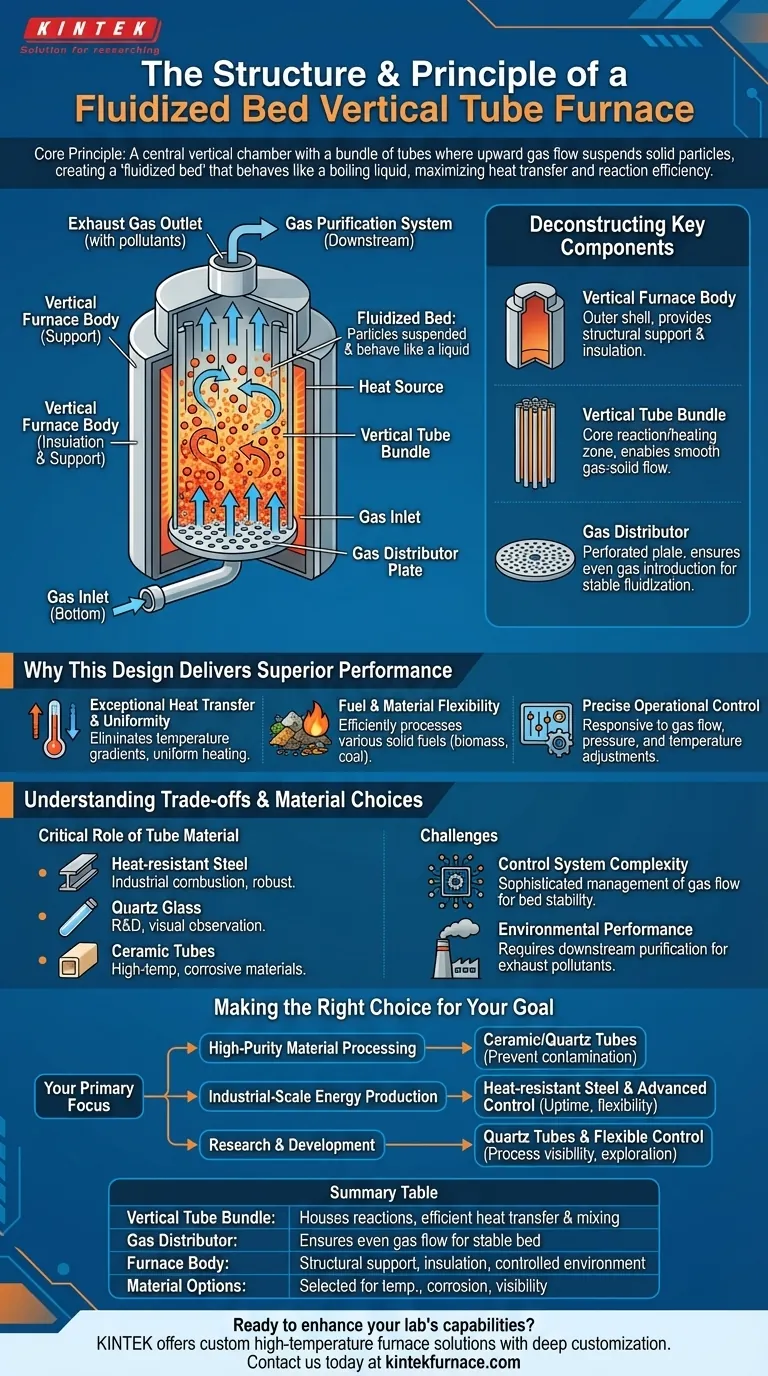

The Core Principle: Harnessing Fluidization

The entire design is built to create and sustain a fluidized bed. Understanding this principle is key to understanding the furnace's structure and high performance.

What is a Fluidized Bed?

A fluidized bed is created when a flow of gas is passed upward through a bed of solid particles. At a specific velocity, the gas flow counteracts gravity, causing the particles to become suspended and move around freely, much like the molecules in a liquid.

The Role of Upward Gas Flow

The furnace's vertical orientation is essential for this process. Gas is introduced at the bottom and flows upwards through a distributor plate, ensuring an even flow across the entire cross-section of the chamber.

Creating an Intense Mixing Zone

This upward flow lifts the solid particles within the vertical tubes. The constant motion, described by friction and vortex effects, creates an extremely large contact area between the gas and the solid particles, dramatically accelerating reactions and heat transfer.

Deconstructing the Furnace's Key Components

The furnace's effectiveness comes from how its main components work together to facilitate the fluidization process.

The Vertical Furnace Body

This is the main outer shell that contains the entire process. It provides structural support and insulation, housing the core components in a controlled environment.

The Vertical Tube Bundle

This is the heart of the furnace. The reaction, combustion, or heating process occurs within these tubes. Their vertical alignment ensures that gas and suspended particles can flow smoothly from bottom to top without obstruction.

The Gas Distributor

Located at the base of the furnace chamber, the gas distributor is a critical component. It's typically a perforated plate that ensures gas is introduced evenly across the bottom of the tube bundle, which is essential for creating a stable and uniform fluidized bed.

Why This Design Delivers Superior Performance

The integration of a vertical structure with fluidized bed technology results in several key operational advantages.

Exceptional Heat Transfer and Uniformity

Because the solid particles are constantly moving and mixing, temperature gradients are virtually eliminated. Every particle is heated uniformly, and heat is transferred from the particles to the tube walls with extreme efficiency.

Fuel and Material Flexibility

The intense mixing and stable combustion conditions allow these furnaces to efficiently process a wide range of solid fuels and materials, including lower-grade fuels like biomass or various types of coal.

Precise Operational Control

The system's performance is highly responsive to operational inputs. By adjusting the gas flow rate, pressure, and temperature, operators can precisely control the reaction speed and heat output, allowing for flexible and repeatable operation.

Understanding the Trade-offs and Material Choices

While powerful, this design requires careful engineering and material selection to function reliably.

The Critical Role of Tube Material

The choice of tube material directly impacts the furnace's application.

- Heat-resistant steel is common for robust, industrial combustion applications.

- Quartz glass is used when visual observation of the process is necessary, common in research and development.

- Ceramic tubes are selected for extremely high-temperature applications or when dealing with highly corrosive materials.

Control System Complexity

Achieving and maintaining a stable fluidized bed is not a simple task. It requires a sophisticated control system to manage gas flow precisely. An unstable bed can lead to poor performance, particle loss, or even operational failure.

Environmental Performance

While combustion is highly efficient, the exhaust gas still contains pollutants. The design must incorporate downstream gas purification and filtering systems to meet modern emission standards, adding to the overall system complexity.

Making the Right Choice for Your Goal

The optimal configuration of a fluidized bed vertical tube furnace depends entirely on its intended application.

- If your primary focus is high-purity material processing: Prioritize ceramic or quartz tubes to prevent contamination and handle potentially corrosive environments.

- If your primary focus is industrial-scale energy production: Choose robust, heat-resistant steel tubes coupled with an advanced control system for maximum uptime and fuel flexibility.

- If your primary focus is research and development: Select a design with quartz tubes for process visibility and a highly flexible control system to explore different operating parameters.

Ultimately, the design of a fluidized bed vertical tube furnace is a masterful integration of physics and engineering to control solids as if they were liquids.

Summary Table:

| Component | Function |

|---|---|

| Vertical Tube Bundle | Houses reactions and enables smooth gas-solid flow for efficient heat transfer and mixing |

| Gas Distributor | Ensures even gas flow at the base to create a stable fluidized bed |

| Furnace Body | Provides structural support, insulation, and a controlled environment for the process |

| Material Options (e.g., Steel, Quartz, Ceramic) | Selected based on application needs like temperature resistance, corrosion handling, or visibility |

Ready to enhance your lab's capabilities with a custom fluidized bed furnace?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in research, industrial production, or material processing, we can help you achieve precise control, superior heat transfer, and operational flexibility.

Contact us today to discuss how our furnaces can optimize your processes and drive your projects forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision