In essence, tube furnaces are used for a vast range of thermal processes where controlling the sample's atmosphere is as important as controlling its temperature. Their primary applications span material synthesis, thermal treatment, and advanced scientific research, including processes like annealing, sintering, purification, calcination, and catalyst testing.

The true value of a tube furnace is not just its ability to heat, but its power to create a highly controlled and uniform thermal environment. This unique capability—enabling work under vacuum, inert gas, or reactive gas—is why it is indispensable in both advanced research and specialized industrial production.

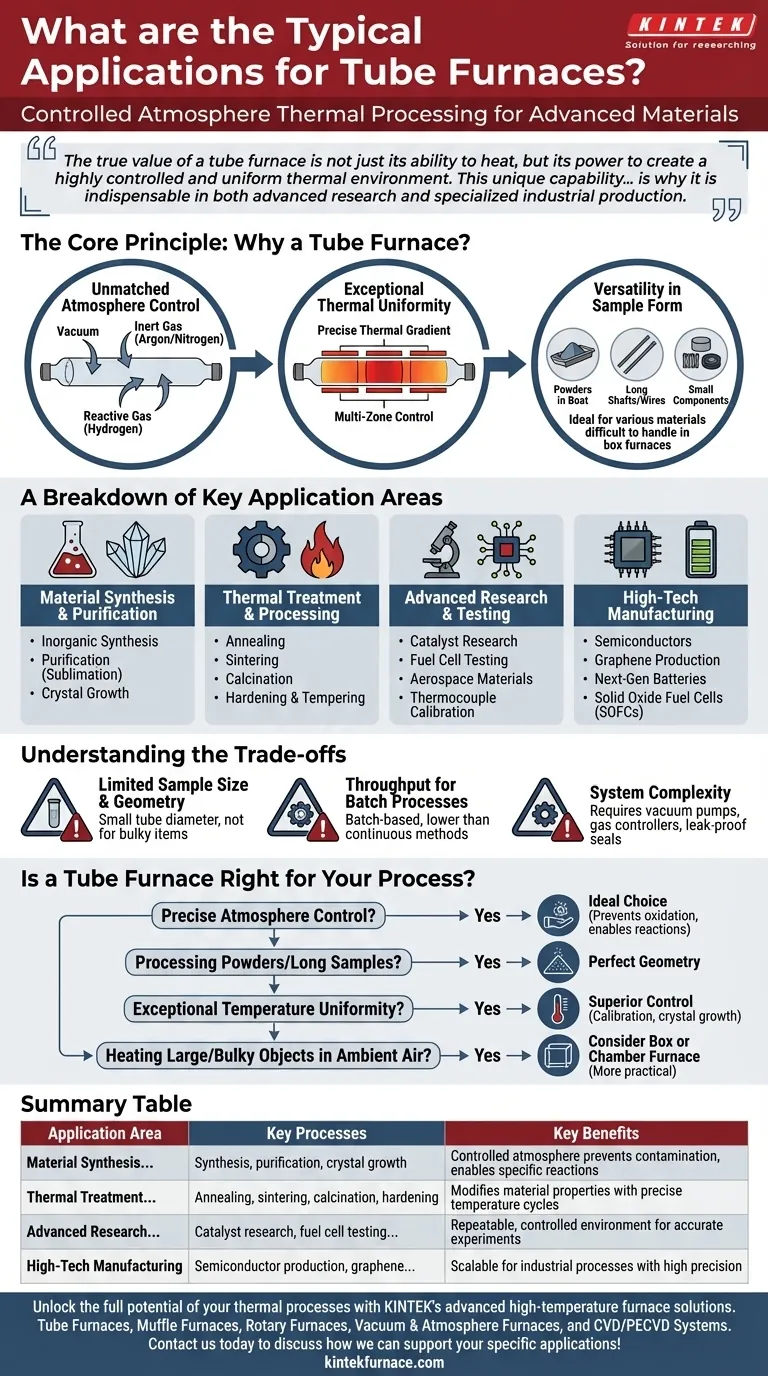

The Core Principle: Why a Tube Furnace?

A tube furnace's design is simple but powerful: heating elements surround a ceramic or metallic tube that contains the sample. This geometry is the source of its unique advantages over other furnace types, like box or muffle furnaces.

Unmatched Atmosphere Control

The defining feature of a tube furnace is its sealed tubular chamber. This allows you to completely control the gaseous environment around your sample.

You can evacuate the tube to create a high-vacuum environment, which is critical for preventing oxidation or contamination during processes like brazing or degassing.

Alternatively, you can flow specific gases through the tube. This enables processes with an inert atmosphere (using Argon or Nitrogen) or a reactive atmosphere (using Hydrogen or other gases for chemical synthesis).

Exceptional Thermal Uniformity

Because the heating elements encircle the sample, tube furnaces can create an exceptionally uniform temperature zone along the length of the tube.

Multi-zone furnaces, with independent heating controls for different sections, offer even greater precision. This is vital for applications like crystal growth or thermocouple calibration, where a precise and stable thermal gradient is required.

Versatility in Sample Form

The tubular shape is ideal for processing materials that are difficult to handle in a box furnace.

This includes long, thin materials like shafts, wires, or strips that can be easily inserted. It is also perfectly suited for processing powders or small components held within quartz or ceramic boats.

A Breakdown of Key Application Areas

The combination of precise temperature and atmosphere control makes the tube furnace a cornerstone tool in numerous fields. Its applications can be grouped into several major categories.

Material Synthesis and Purification

This is a primary use in chemistry and materials science. The controlled environment prevents unwanted side reactions and contamination.

Common processes include the synthesis of inorganic compounds, purification of materials through sublimation, and crystal growth from a vapor or melt.

Thermal Treatment and Processing

Tube furnaces are widely used to modify the physical properties of materials through carefully controlled heating and cooling cycles.

Key applications are annealing to relieve internal stresses, sintering to fuse powders into a solid mass, calcination to thermally decompose materials, and hardening or tempering metals.

Advanced Research and Testing

In a research setting, the tube furnace provides a repeatable and tightly controlled environment for experimentation.

It is integral for catalyst research, fuel cell testing, and testing the performance of aerospace ceramics and metals under extreme heat. It is also the standard for high-accuracy thermocouple calibration.

High-Tech Manufacturing

The principles proven in the lab are scaled up for specialized industrial production.

Tube furnaces are critical in manufacturing semiconductors, producing advanced materials like graphene and polymer composites, and in the production of next-generation batteries and solid oxide fuel cells (SOFCs).

Understanding the Trade-offs

While incredibly versatile, a tube furnace is not the solution for every heating application. Understanding its limitations is key to using it effectively.

Limited Sample Size and Geometry

The most obvious limitation is the tube's diameter. Tube furnaces are unsuitable for heating large, bulky, or irregularly shaped objects. For these tasks, a chamber or box furnace is a better choice.

Throughput for Batch Processes

Many laboratory tube furnace applications are batch-based, meaning one sample (or a small boat of samples) is processed at a time. While continuous-feed systems exist, the throughput can be lower than other large-scale industrial heating methods.

System Complexity

Achieving and maintaining a high-purity atmosphere or a deep vacuum requires more than just the furnace. It necessitates a system of vacuum pumps, gas flow controllers, and secure, leak-proof flanges, which adds to the operational complexity and cost.

Is a Tube Furnace Right for Your Process?

Choosing the correct thermal equipment depends entirely on your specific goal. Use these points as a guide.

- If your primary focus is precise atmosphere control (inert, reactive, or vacuum): A tube furnace is the ideal choice for preventing oxidation or enabling specific chemical reactions.

- If your primary focus is processing powders, small parts, or long, thin samples: The geometry of a tube furnace is perfectly suited for these material forms.

- If your process requires exceptional temperature uniformity along a defined axis: A single or multi-zone tube furnace offers superior control for applications like calibration or crystal growth.

- If your primary focus is heating large, bulky, or irregularly shaped objects in ambient air: A box or chamber furnace is a more practical and cost-effective solution.

Understanding that a tube furnace is fundamentally a tool for environmental control empowers you to leverage it for the most demanding thermal processing challenges.

Summary Table:

| Application Area | Key Processes | Key Benefits |

|---|---|---|

| Material Synthesis and Purification | Synthesis, purification, crystal growth | Controlled atmosphere prevents contamination, enables specific reactions |

| Thermal Treatment and Processing | Annealing, sintering, calcination, hardening | Modifies material properties with precise temperature cycles |

| Advanced Research and Testing | Catalyst research, fuel cell testing, thermocouple calibration | Repeatable, controlled environment for accurate experiments |

| High-Tech Manufacturing | Semiconductor production, graphene, batteries, SOFCs | Scalable for industrial processes with high precision |

Unlock the full potential of your thermal processes with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency and accuracy. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety