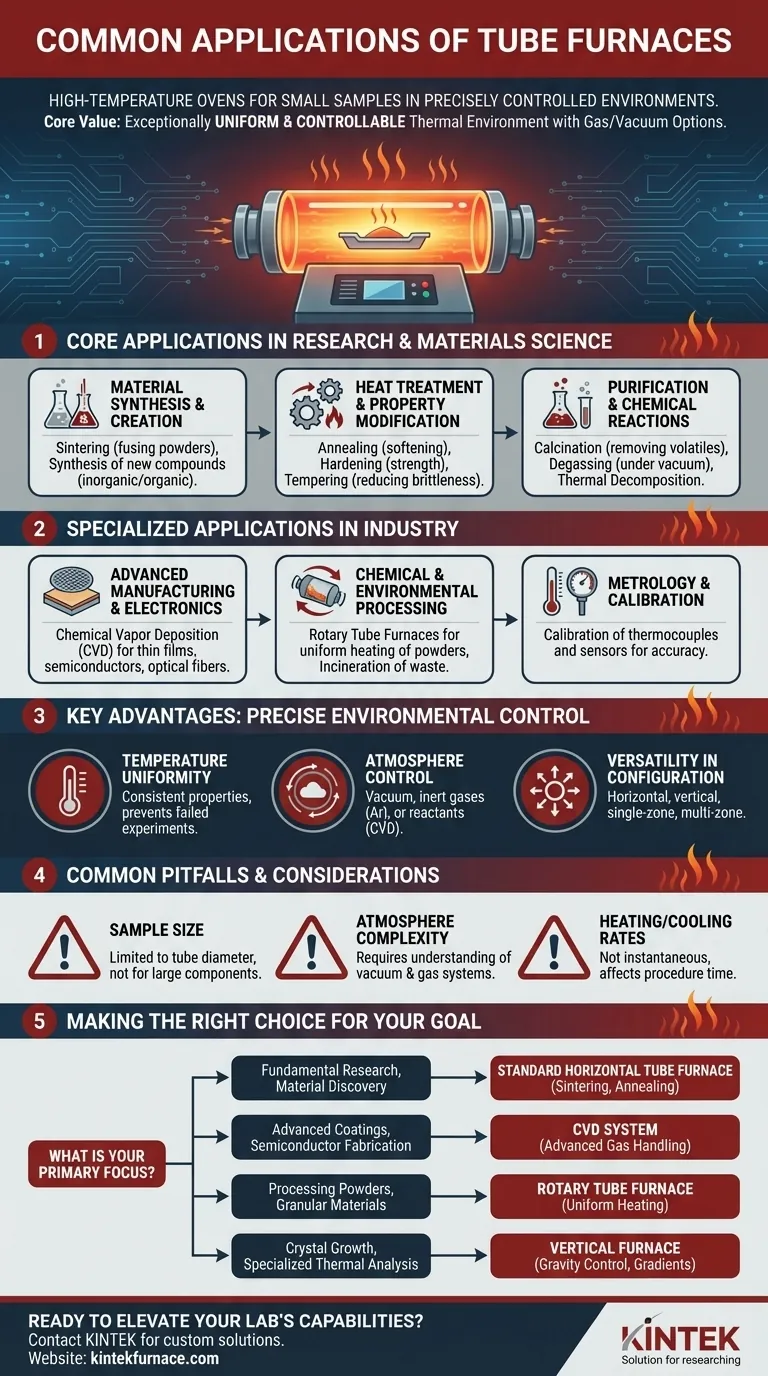

In essence, a tube furnace is a high-temperature oven used for processing small samples in a precisely controlled environment. Common applications range from synthesizing new materials and modifying the properties of existing ones through heat treatment to purifying compounds and calibrating precision instruments.

The core value of a tube furnace is not just its ability to generate high temperatures, but its capacity to create an exceptionally uniform and controllable thermal environment, often combined with a specific gas atmosphere or vacuum, which is critical for advanced research and manufacturing.

Core Applications in Research and Materials Science

The majority of tube furnace applications are found in laboratory settings, where precision and repeatability are paramount.

Material Synthesis and Creation

Tube furnaces are central to creating new materials from their constituent elements or compounds. This includes sintering, a process that uses heat to fuse powders into a solid mass, which is fundamental in creating ceramics and metallurgical components. They are also used for the synthesis of both inorganic and organic compounds.

Heat Treatment and Property Modification

Scientists and engineers use tube furnaces to alter the physical properties of materials. Processes like annealing (softening metals), hardening (increasing strength), and tempering (reducing brittleness) all rely on precise heating and cooling cycles that are easily managed within a tube furnace.

Purification and Chemical Reactions

The sealed environment of a tube furnace is ideal for high-temperature chemical processes. Calcination uses heat to drive off volatile substances, while degassing removes dissolved gases from a material under vacuum. It is also used for thermal decomposition, where compounds are broken down by heat into simpler substances.

Specialized Applications in Industry

While primarily a lab tool, the principles of the tube furnace are scaled and adapted for specific industrial processes.

Advanced Manufacturing and Electronics

Chemical Vapor Deposition (CVD) is a critical process where a tube furnace is used to deposit a thin, high-purity film onto a substrate. This is fundamental in the manufacturing of semiconductors, optical fibers, and protective coatings. The furnace provides the necessary heat and controlled atmosphere for the chemical reactions to occur on the substrate's surface.

Chemical and Environmental Processing

Rotary tube furnaces, which rotate during operation, are used to process granular or powdered materials continuously. They ensure every particle is heated uniformly, making them ideal for the large-scale calcination of chemical raw materials or the incineration of solid waste and sludge in environmental applications.

Metrology and Calibration

The exceptional temperature uniformity and stability of a tube furnace make it a perfect environment for the calibration of thermocouples and other temperature sensors, ensuring they provide accurate readings in their own industrial or scientific applications.

Understanding the Key Advantage: Precise Environmental Control

The wide range of applications stems from one defining characteristic: control. A tube furnace allows a user to precisely manage the conditions a sample is exposed to.

The Importance of Temperature Uniformity

For processes like annealing or sintering, any variation in temperature across the sample can lead to inconsistent material properties and failed experiments. A tube furnace is designed to provide a highly uniform hot zone, ensuring the entire sample is processed equally.

The Power of Atmosphere Control

The sealed tube allows for the complete evacuation of air (creating a vacuum) or the introduction of specific gases. This is crucial for preventing oxidation when heating metals (using an inert gas like argon) or for providing the necessary reactants for processes like CVD.

Versatility in Configuration

Tube furnaces come in various configurations—horizontal, vertical, single-zone, or multi-zone—to suit different needs. Vertical furnaces, for example, are ideal for processes where gravity is a factor or when a specific temperature gradient, rather than uniformity, is desired.

Common Pitfalls and Considerations

While powerful, a tube furnace is a specialized tool with inherent trade-offs that must be understood.

Sample Size and Throughput

By design, tube furnaces are intended for smaller samples that fit within the diameter of the process tube. They are not suited for processing large or bulky components, which would require a chamber or box furnace instead.

Complexity of Atmosphere Control

While atmosphere control is a major benefit, implementing it requires a proper understanding of vacuum systems, gas flow controllers, and safety protocols. An improperly managed system can lead to failed experiments or safety hazards.

Heating and Cooling Rates

The thermal mass of the furnace's insulation and heating elements dictates its heat-up and cool-down rates. While modern designs are highly efficient, these rates are not instantaneous and must be factored into the experimental procedure, especially for materials sensitive to thermal shock.

Making the Right Choice for Your Goal

To select the right approach, align the furnace's capabilities with your primary objective.

- If your primary focus is fundamental research and material discovery: A standard horizontal tube furnace offers the best balance of flexibility and control for common processes like sintering, annealing, and synthesis.

- If your primary focus is advanced coatings or semiconductor fabrication: You will need a system specifically designed for Chemical Vapor Deposition (CVD), which includes advanced gas handling and control.

- If your primary focus is processing powders or granular materials: A rotary tube furnace is designed to ensure uniform heating for these sample types, which is difficult to achieve in a static furnace.

- If your primary focus is crystal growth or specialized thermal analysis: A vertical furnace offers superior control over gravity's effects and allows for the creation of precise temperature gradients along the tube's length.

Ultimately, a tube furnace is the instrument of choice whenever precise control over a material's thermal and atmospheric environment is the key to success.

Summary Table:

| Application | Key Processes | Industries/Benefits |

|---|---|---|

| Material Synthesis | Sintering, Synthesis | Research, Ceramics, Metallurgy |

| Heat Treatment | Annealing, Hardening, Tempering | Materials Science, Engineering |

| Purification & Reactions | Calcination, Degassing, Thermal Decomposition | Chemical, Environmental |

| Advanced Manufacturing | Chemical Vapor Deposition (CVD) | Semiconductors, Electronics |

| Industrial Processing | Rotary Furnace Operations | Large-scale Calcination, Incineration |

| Metrology | Calibration of Thermocouples | Instrument Accuracy, Quality Control |

Ready to elevate your lab's capabilities with a custom tube furnace solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in materials science, electronics, or chemical processing, we can help you achieve superior temperature control and efficiency. Contact us today to discuss your needs and discover how our tailored solutions can drive your research forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide