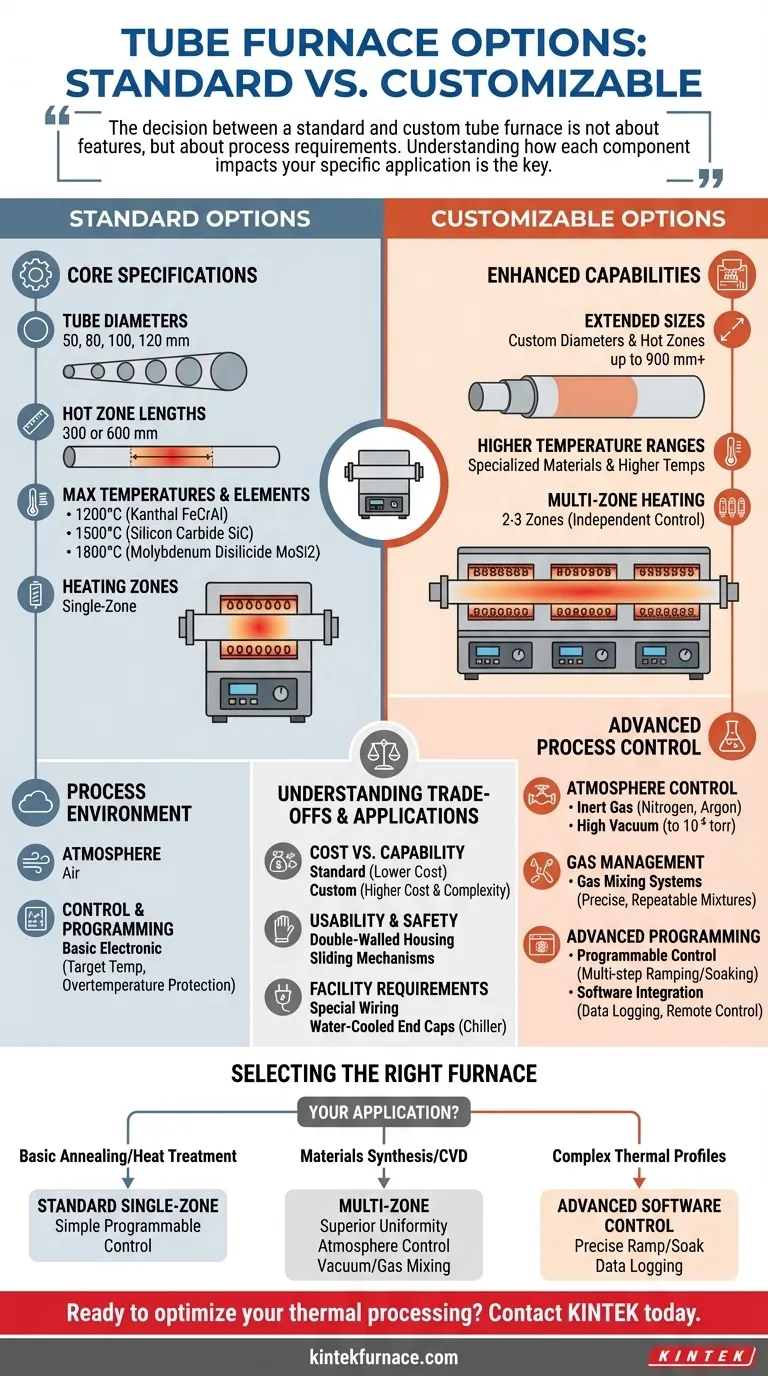

At its core, a tube furnace's configuration is defined by a few key parameters. Standard options typically include tube diameters of 50, 80, 100, or 120 mm, heated "hot zone" lengths of 300 or 600 mm, and maximum temperatures of 1200°C, 1500°C, or 1800°C. Customization extends these fundamental specifications and adds critical capabilities for process control, such as multi-zone heating, vacuum and inert gas atmosphere control, and advanced programming.

The decision between a standard and custom tube furnace is not about features, but about process requirements. Understanding how each component—from the heating element to the control software—impacts your specific application is the key to specifying the right tool for the job.

Deconstructing the Core Furnace Specifications

Every tube furnace is built around a set of core physical and thermal characteristics. These fundamental choices dictate the furnace's primary capabilities and cost.

Temperature Range and Heating Elements

The maximum operating temperature is arguably the most critical specification, as it determines the types of processes you can run. This temperature is directly tied to the heating element material.

- Up to 1200°C: Furnaces in this range typically use Kanthal (FeCrAl) alloy elements. This is a cost-effective choice suitable for general-purpose heat treatment and annealing.

- Up to 1500°C-1600°C: These furnaces rely on Silicon Carbide (SiC) elements. They offer a significant step up in temperature for more demanding materials processing.

- Up to 1800°C: The highest standard temperatures are achieved with Molybdenum Disilicide (MoSi2) elements. These are necessary for sintering advanced ceramics and other high-temperature research.

Physical Dimensions: Tube Diameter and Hot Zone

The furnace's physical size determines your sample throughput and processing capacity.

Standard tube diameters (50 mm to 120 mm) define the maximum size of the sample or substrate you can process.

The hot zone is the length of the tube that maintains the specified temperature uniformity. Standard lengths are often 300 mm or 600 mm, while custom options can extend to 900 mm or more.

Single-Zone vs. Multi-Zone Heating

A single-zone furnace has one controller and one set of heating elements, creating a hot zone that is most uniform in the very center and cools toward the ends. This is sufficient for many basic applications.

A multi-zone furnace (often with two or three zones) uses multiple independent controllers. This allows for shaping the temperature profile, either to create a deliberate gradient for transport experiments or, more commonly, to create a significantly larger and more uniform hot zone in the center.

Controlling the Process Environment

For most advanced materials work, controlling the atmosphere inside the tube is as important as controlling the temperature. This is where customization becomes essential.

Atmosphere Control: From Air to High Vacuum

By sealing the ends of the process tube with specialized end caps, you can control the internal environment.

- Inert Gas: The most common application is flowing an inert gas like nitrogen or argon through the tube to prevent oxidation of the sample at high temperatures.

- High Vacuum: For applications demanding extreme purity, flange assemblies can be connected to a vacuum pump. This allows for evacuating the tube to pressures as low as 10⁻⁵ torr, removing nearly all atmospheric contaminants.

Gas Management and Mixing Systems

For processes like Chemical Vapor Deposition (CVD), precise control over multiple process gases is required. Optional gas mixing systems can be integrated to deliver specific, repeatable gas mixtures to the furnace chamber.

Temperature Control and Programming

The level of control determines the precision and repeatability of your thermal process.

- Basic Electronic Control: Standard controllers allow you to set a target temperature and provide overtemperature protection.

- Programmable Control: More advanced digital controllers allow for creating multi-step programs with specific ramping rates (how fast to heat up/cool down) and soaking times (how long to hold at a temperature).

- Software Integration: Full software suites provide a graphical interface for programming, remote control of the furnace, and, most importantly, data acquisition and logging for quality control and research records.

Understanding the Trade-offs

Choosing the right features involves balancing capability against complexity and cost. Every added function has an implication.

Cost vs. Capability

Each upgrade—from a higher temperature range to multi-zone control or vacuum compatibility—significantly increases the furnace's cost and complexity. A standard 1200°C air furnace is a fraction of the cost of a multi-zone 1800°C vacuum furnace.

Usability and Safety

Modern furnaces often include user-focused features. A double-walled housing keeps the exterior surface cool to the touch even at high internal temperatures. A sliding mechanism can allow the furnace body to be moved away from the tube for rapid cooling and easy sample loading.

Facility Requirements

Custom features can impact your lab's infrastructure. High-power furnaces may require special electrical wiring. Systems with water-cooled end caps, which are used to protect o-rings and flanges during high-temperature operation, require a reliable water supply or a dedicated chiller.

Selecting the Right Furnace for Your Application

Your choice should be driven entirely by the demands of your specific scientific or production goals.

- If your primary focus is basic annealing or heat treatment in air: A standard single-zone furnace with a simple programmable controller is an efficient and cost-effective solution.

- If your primary focus is materials synthesis or CVD: Prioritize a multi-zone configuration for superior temperature uniformity and a robust atmosphere control system with options for both vacuum and gas mixing.

- If your primary focus is research with complex thermal profiles: Invest in a system with advanced software control for precise ramp/soak programming and comprehensive data logging for process traceability.

By carefully matching the furnace's capabilities to your process needs, you ensure you are specifying a tool that is not just functional, but optimal for your work.

Summary Table:

| Specification | Standard Options | Customizable Options |

|---|---|---|

| Tube Diameter | 50, 80, 100, 120 mm | Extended sizes |

| Hot Zone Length | 300, 600 mm | Up to 900 mm or more |

| Max Temperature | 1200°C, 1500°C, 1800°C | Higher ranges |

| Heating Elements | Kanthal, SiC, MoSi2 | Specialized materials |

| Control Zones | Single-zone | Multi-zone (2-3 zones) |

| Atmosphere | Air | Vacuum, inert gas, gas mixing |

| Programming | Basic | Advanced with data logging |

Ready to optimize your thermal processing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can tailor a tube furnace to enhance your research and production efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing