At its core, a vertical tube furnace's flexibility stems from its ability to be extensively customized and to operate under a wide range of controlled atmospheres. This adaptability allows it to handle diverse materials and processes, from high-purity synthesis to semiconductor fabrication, by precisely tailoring its physical configuration and internal environment to the specific scientific or production requirement.

The true value of a vertical tube furnace lies not just in its individual features, but in how its vertical orientation combines with deep customization to enable processes that are difficult or inefficient to perform in other furnace types. Understanding this synergy is key to leveraging its full potential.

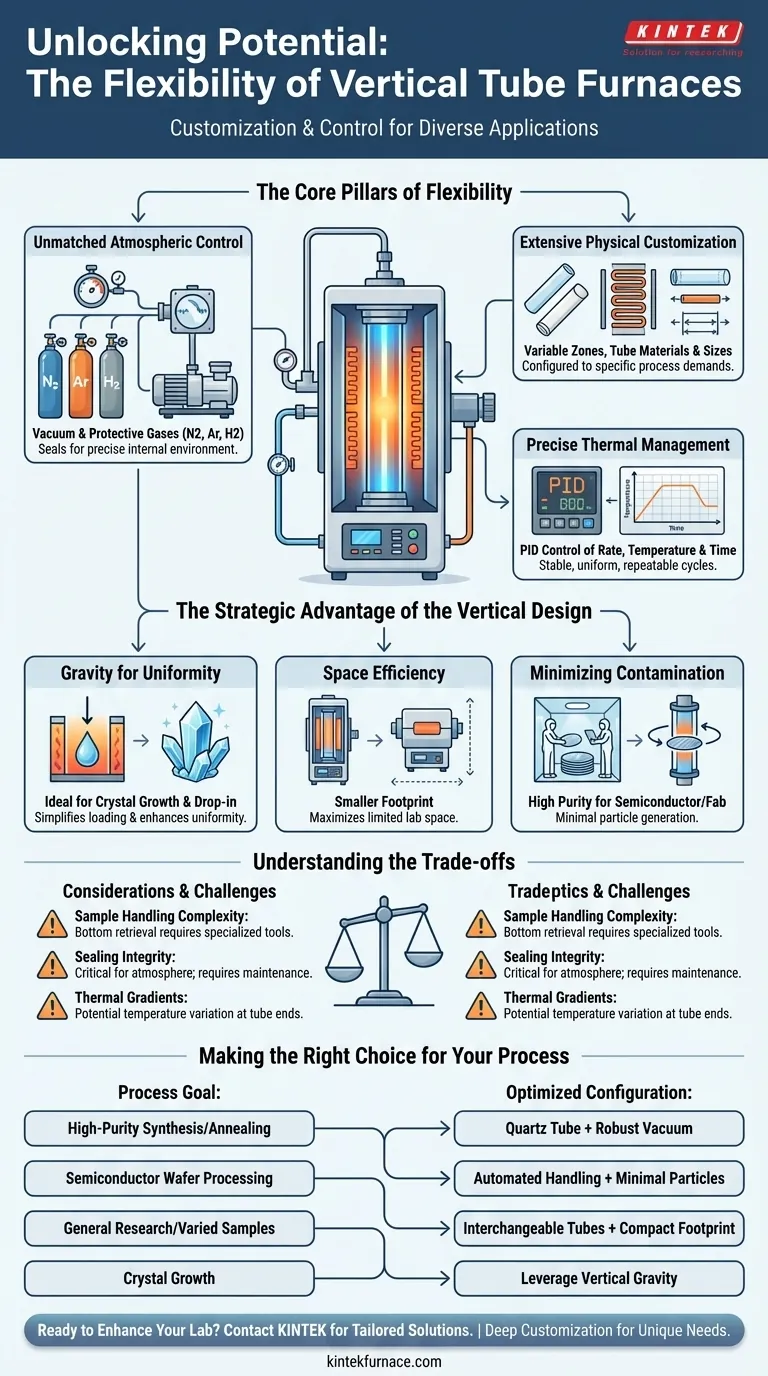

The Core Pillars of Flexibility

A vertical tube furnace's reputation for diversity is built on two fundamental capabilities: its control over the internal atmosphere and its physical adaptability.

Unmatched Atmospheric Control

A primary advantage is the ability to move beyond simple heating in ambient air. The system is designed to be sealed, allowing you to create a highly specific internal environment.

This includes running processes under a pre-vacuum to remove contaminants or operating with various protective and reactive gases. Common examples include inert gases like nitrogen (N2) and argon (Ar) to prevent oxidation, or reactive gases like hydrogen (H2) for specific chemical reduction processes.

Extensive Physical Customization

These furnaces are rarely one-size-fits-all. They are typically configured to meet the demands of a specific process.

Key customization options include the number of heating zones, the furnace tube material (e.g., quartz for purity, alumina for higher temperatures), and the tube's diameter and length. This ensures the furnace perfectly accommodates the sample size and required thermal profile.

Precise Thermal Profile Management

Flexibility is meaningless without control. Vertical tube furnaces use advanced control systems, often with PID (Proportional-Integral-Derivative) controllers, to manage the thermal cycle with high precision.

Users can precisely define the heating rate, the target temperature, and the holding time. This level of control ensures that thermal processes are stable, uniform, and, most importantly, repeatable.

The Strategic Advantage of the Vertical Design

The vertical orientation is not merely an aesthetic choice; it provides distinct process advantages that enhance the furnace's flexibility.

Leveraging Gravity for Uniformity

In many processes, gravity is a powerful tool. The vertical setup is ideal for applications where gravity assists in achieving uniform results, such as certain types of crystal growth or chemical vapor deposition.

It also simplifies sample loading for specific experiments. Samples can be easily dropped from the top into the hot zone, which is a requirement for certain material testing and thermal shock studies.

Space Efficiency and Footprint

For laboratories where floor space is a premium, the smaller footprint of a vertical furnace compared to its horizontal equivalent is a significant practical benefit. It allows for advanced thermal processing capabilities without occupying excessive lab space.

Minimizing Contamination

In high-purity applications like semiconductor manufacturing, the vertical design helps to achieve minimal particle generation. When combined with automated wafer and boat transfer systems, it creates a highly controlled, clean environment that boosts productivity and yield.

Understanding the Trade-offs

While powerful, the flexibility of a vertical tube furnace comes with inherent complexities and considerations that must be managed.

Sample Handling and Accessibility

Loading samples via drop-in is straightforward, but retrieving them from the bottom of a hot tube can be more complex than simply pulling a boat out of a horizontal furnace. This often requires specialized tongs or automated lift systems, which can add to the cost and operational complexity.

Sealing and Atmosphere Integrity

Achieving a perfect seal is critical for maintaining atmospheric control. Improperly fitted flanges or worn-out O-rings can lead to leaks, compromising the vacuum or protective gas environment and ruining an experiment. This requires diligent maintenance and careful setup.

Thermal Gradients

While vertical furnaces provide excellent temperature uniformity along their length, there can still be thermal gradients at the very top and bottom of the tube. For processes requiring absolute uniformity across the entire sample, the sample's length must be carefully positioned within the furnace's central "flat zone."

Making the Right Choice for Your Process

The optimal configuration depends entirely on your end goal. By matching the furnace's capabilities to your process needs, you can unlock its full potential.

- If your primary focus is high-purity material synthesis or annealing: Prioritize a high-purity quartz tube and a robust vacuum system to ensure complete atmospheric control.

- If your primary focus is semiconductor wafer processing: Invest in a system designed for minimal particle generation with automated wafer handling to maximize yield and purity.

- If your primary focus is general research with varied samples: Select a model with easily interchangeable tube diameters and a smaller footprint to maximize versatility in a constrained lab space.

- If your primary focus is processes like crystal growth: The vertical orientation's ability to leverage gravity for uniformity is your most critical feature.

Ultimately, a vertical tube furnace is a versatile tool designed to be precisely molded to the demands of your specific application.

Summary Table:

| Aspect | Key Features |

|---|---|

| Atmospheric Control | Sealed design for vacuum, inert gases (N2, Ar), reactive gases (H2) |

| Physical Customization | Multiple heating zones, tube materials (quartz, alumina), diameter/length options |

| Thermal Management | PID controllers for precise heating rates, temperatures, holding times |

| Vertical Design | Gravity-assisted uniformity, space efficiency, minimal contamination |

| Applications | High-purity synthesis, semiconductor fabrication, crystal growth, research |

Ready to enhance your lab's capabilities with a tailored vertical tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs precisely. Contact us today to discuss how we can optimize your processes and boost efficiency!

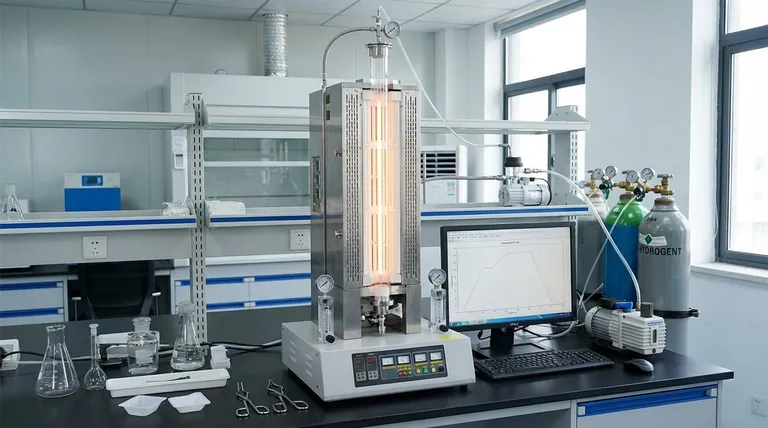

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab