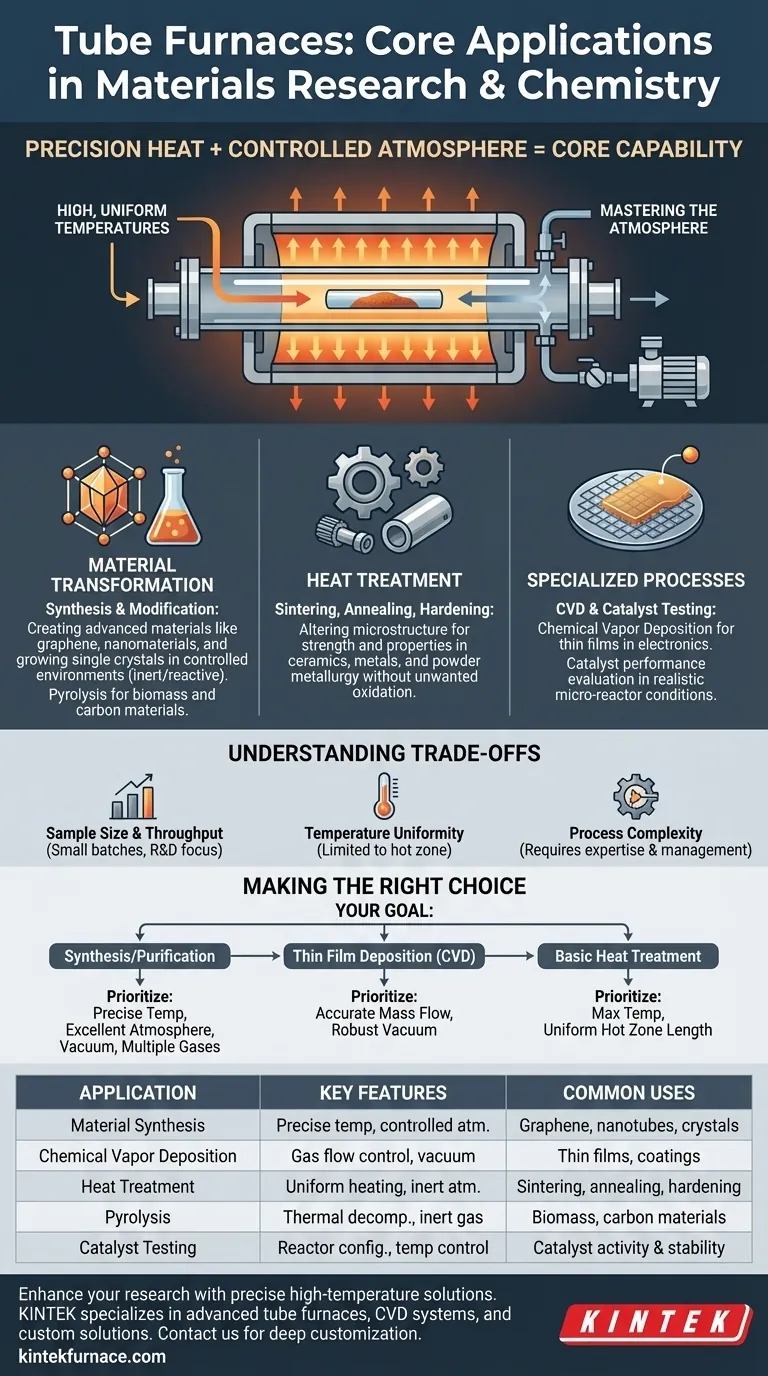

In short, tube furnaces are used for any high-temperature process that requires precise control over the sample's atmosphere. This core capability makes them indispensable for synthesizing novel materials like graphene, performing heat treatments such as annealing and sintering, and depositing thin films via chemical vapor deposition (CVD) for electronics and coatings.

The power of a tube furnace is not just its ability to reach high temperatures. Its true value lies in the sealed tube design, which allows researchers to create, maintain, and modify a highly controlled gas environment—from a pure vacuum to a reactive chemical atmosphere—around a sample during processing.

The Foundation: Why a Tube, Not a Box?

The unique geometry of a tube furnace is what unlocks its core applications. Unlike a simple box furnace or oven, a tube furnace isolates the sample within a contained, sealed environment, enabling two critical functions simultaneously.

Achieving High, Uniform Temperatures

The heating elements encircle a ceramic or quartz tube, creating a zone of consistent temperature. This allows for precise thermal processing, where maintaining a specific temperature or following a programmed heating and cooling rate is essential for the material's final properties.

Mastering the Atmosphere

The ends of the tube can be sealed with flanges connected to gas lines and vacuum pumps. This gives a researcher complete authority over the chemical environment, enabling processes that are impossible in open air, such as working with oxygen-sensitive materials or introducing specific reactive gases.

Core Applications in Material Transformation

The combination of heat and atmospheric control makes the tube furnace a versatile platform for creating and modifying materials at a fundamental level.

Synthesis of Advanced Materials

Tube furnaces are central to creating materials with novel properties. This includes growing single crystals for electronics, preparing inorganic compounds, and synthesizing nanomaterials like carbon nanotubes and graphene, which often require specific precursor gases and the complete absence of oxygen.

Thermal Decomposition and Pyrolysis

Pyrolysis is the process of thermally decomposing a material in an inert (non-reactive) atmosphere. In a tube furnace, a sample can be heated under a flow of nitrogen or argon, causing it to break down into simpler components without combusting. This is used in biomass research and to create specialized carbon materials.

Heat Treatment: Sintering, Annealing, and Hardening

These processes use heat to alter a material's microstructure, not to change its chemical composition.

- Sintering compacts powders into a solid mass, essential in ceramics and powder metallurgy.

- Annealing and Hardening modify the properties of metals and other materials to make them stronger or less brittle. The controlled atmosphere prevents unwanted oxidation at high temperatures.

Specialized Processes and Research

Beyond general heat treatment, tube furnaces are critical for more complex, dynamic chemical processes.

Chemical Vapor Deposition (CVD)

CVD is a cornerstone technique in semiconductor manufacturing and nanotechnology. Precursor gases are introduced into the hot tube, where they react and deposit a solid, high-purity thin film onto a substrate. The tube furnace provides the perfect environment for this delicate process.

Catalyst Research and Testing

To evaluate the performance of a catalyst, it must be tested under realistic operating conditions. A tube furnace can be configured as a small-scale reactor, allowing researchers to flow specific reactants over a catalyst bed at a set temperature to measure its activity and stability over time.

Understanding the Trade-offs

While powerful, tube furnaces have inherent limitations that are important to recognize.

Sample Size and Throughput

Most laboratory tube furnaces are designed for research and development, not mass production. The diameter and length of the tube restrict sample size, making them best suited for processing small batches of material.

Temperature Uniformity

The "hot zone," or the area of most uniform temperature, is typically limited to the central portion of the tube. Samples placed too close to the ends may experience temperature gradients, which can affect experimental consistency.

Process Complexity

Operating a tube furnace for advanced applications like CVD requires careful management of multiple systems, including temperature programmers, gas flow controllers, and vacuum pumps. This demands a higher level of operator expertise compared to a simple oven.

Making the Right Choice for Your Goal

The specific features you need in a tube furnace depend entirely on your intended application.

- If your primary focus is synthesis or purification: Prioritize precise temperature programming and excellent atmospheric control with a good vacuum system and multiple gas inlets.

- If your primary focus is thin film deposition (CVD): You will require a system with highly accurate mass flow controllers for precursor gases and a robust vacuum system.

- If your primary focus is basic heat treatment (annealing, sintering): Your main concerns will be the maximum operating temperature and the length of the uniform hot zone.

Ultimately, a tube furnace is a foundational tool that transforms a simple heating process into a highly controlled, repeatable scientific experiment.

Summary Table:

| Application | Key Features | Common Uses |

|---|---|---|

| Material Synthesis | Precise temperature, controlled atmosphere | Graphene, carbon nanotubes, single crystals |

| Chemical Vapor Deposition (CVD) | Gas flow control, vacuum systems | Thin films for electronics, coatings |

| Heat Treatment | Uniform heating, inert atmospheres | Annealing, sintering, hardening of metals and ceramics |

| Pyrolysis | Thermal decomposition in inert gas | Biomass research, carbon material production |

| Catalyst Testing | Reactor configuration, temperature control | Activity and stability evaluation of catalysts |

Ready to enhance your materials research with precise high-temperature solutions? KINTEK specializes in advanced tube furnaces and custom systems for synthesis, CVD, and heat treatment. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Contact us today to discuss how our deep customization capabilities can optimize your laboratory processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety