In material processing, temperature is not just a setting; it is the primary tool for transformation. Precise temperature control in a tubular furnace is critical because it ensures process repeatability and allows for the intentional manipulation of a material's fundamental properties. Without it, you cannot reliably achieve the desired composition, crystal structure, or microstructure, leading to inconsistent results and product failure.

Your process is not simply "heating an object." You are executing a precise thermal recipe. Precise temperature control is what guarantees that the final properties of your material are a direct, repeatable result of your process, not a matter of chance.

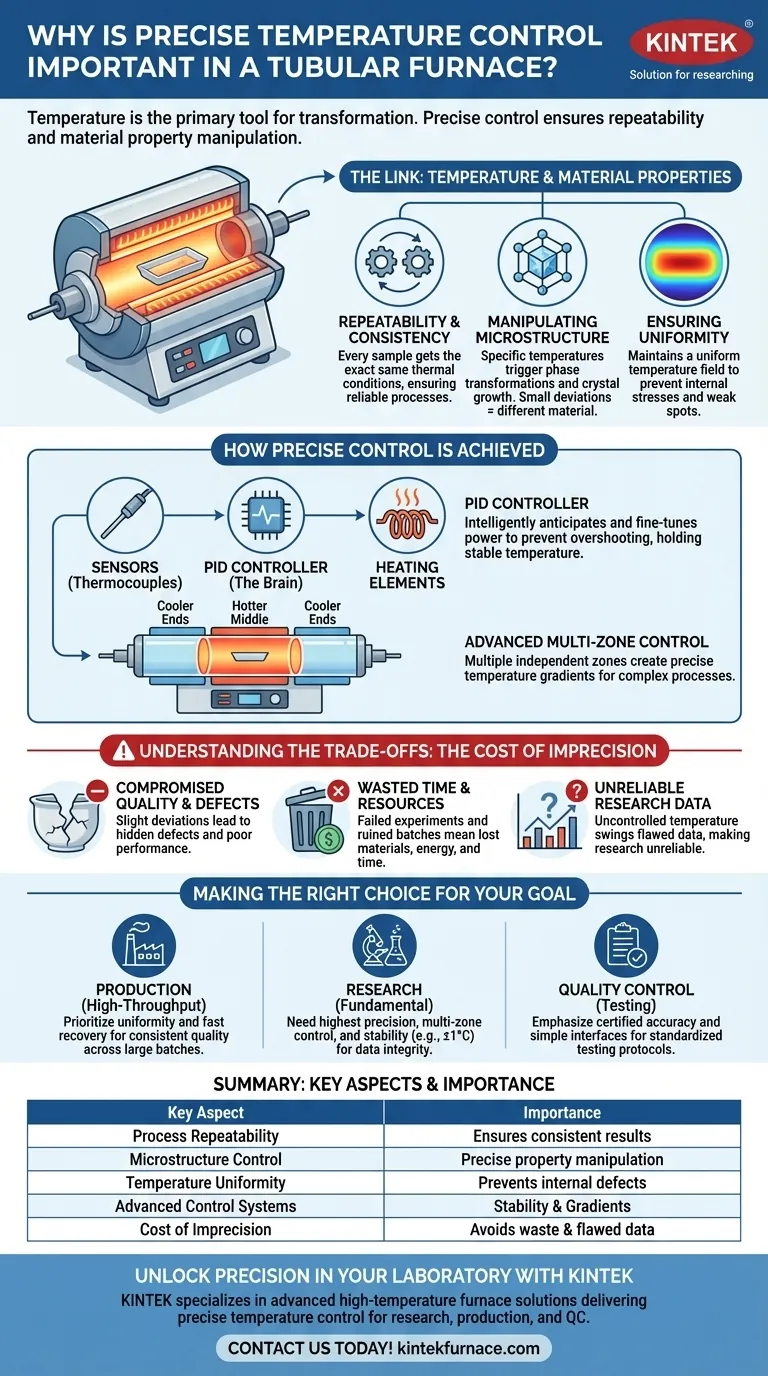

The Link Between Temperature and Material Properties

The core function of a furnace is to induce a specific change in a material. That change is almost always dictated by a precise temperature profile—not just a peak temperature, but the rate of heating, the duration at temperature (soak time), and the rate of cooling.

Achieving Repeatability and Consistency

In any scientific or industrial application, from research to manufacturing, the process must be repeatable. If you run the same process today and tomorrow, you must get the identical outcome.

Temperature fluctuation is a primary source of variation. Precise control ensures that every sample is subjected to the exact same thermal conditions, making processes like sintering, annealing, and brazing reliable and consistent.

Manipulating Microstructure and Crystal Phase

The properties of most advanced materials—their strength, conductivity, or optical characteristics—are determined by their internal structure at the microscopic level.

Specific temperatures act as triggers for phase transformations, crystal growth, or the bonding of particles. A deviation of even a few degrees can mean you miss a critical transition point, resulting in a completely different, and often useless, final material.

Ensuring Temperature Uniformity

A tubular furnace heats a sample along its length. "Precise control" isn't just about one point in the furnace hitting the target temperature; it's about maintaining a uniform temperature field across the entire working zone.

Uneven heating leads to a material with different properties at different points, creating internal stresses and weak spots that compromise the integrity of the final component.

How Precise Control is Achieved

Modern furnaces employ sophisticated systems to move beyond simple on/off heating and achieve the high degree of control required for technical applications.

The Role of Sensors and Controllers

High-accuracy thermocouples act as the furnace's nervous system, constantly measuring the temperature inside the tube.

This data is fed to a PID controller (Proportional-Integral-Derivative), which acts as the brain. It doesn't just turn the heater off when the temperature is met; it intelligently anticipates, calculates, and fine-tunes the power output to prevent overshooting and minimize fluctuations, holding the temperature remarkably stable.

Advanced Multi-Zone Control

For more complex processes like chemical vapor deposition or targeted crystal growth, single-zone control is insufficient.

High-end tubular furnaces feature multi-zone heating. They have several independent heating elements and controllers along the length of the tube. This allows you to create a precise temperature gradient—for example, hotter in the middle and cooler at the ends—giving you an additional layer of control over your process.

Understanding the Trade-offs: The Cost of Imprecision

Investing in precise temperature control is not an expense; it is insurance against failure. The consequences of poor control are significant and costly.

Compromised Quality and Defects

For materials like ceramics or porcelain, slight temperature deviations can be catastrophic. If the temperature is too low, particles may not fuse properly. If it's too high, the material can warp or melt.

The result is a product with hidden defects that compromise its quality, durability, and performance.

Wasted Time and Resources

A failed experiment or a ruined production batch due to poor temperature control means more than just a bad outcome. It represents wasted materials, squandered energy, and, most importantly, lost time.

Unreliable Research Data

For a researcher, control over variables is paramount. If you cannot guarantee that the temperature was stable and accurate throughout your experiment, your data is fundamentally flawed.

You cannot confidently attribute a change in the material to your intended variable if an uncontrolled temperature swing could have been the actual cause.

Making the Right Choice for Your Goal

Your required level of temperature precision depends directly on your application.

- If your primary focus is high-throughput production: Prioritize furnaces with excellent temperature uniformity and fast recovery times to ensure consistent quality across large batches.

- If your primary focus is fundamental research: You need the highest level of precision, including features like multi-zone control and tight temperature stability (e.g., ±1°C), to guarantee data integrity.

- If your primary focus is quality control testing (like LOI): Emphasize furnaces with certified accuracy and simple, programmable interfaces to ensure standardized and repeatable testing protocols.

Ultimately, mastering temperature control is mastering your material's final form and function.

Summary Table:

| Key Aspect | Importance |

|---|---|

| Process Repeatability | Ensures consistent results in sintering, annealing, and brazing processes |

| Microstructure Control | Allows precise manipulation of material properties like strength and conductivity |

| Temperature Uniformity | Prevents internal stresses and defects across the sample |

| Advanced Control Systems | Utilizes PID controllers and multi-zone heating for stability and gradients |

| Cost of Imprecision | Avoids wasted resources, flawed data, and compromised product quality |

Unlock Precision in Your Laboratory with KINTEK

Are you struggling with inconsistent results or material defects due to poor temperature control? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed to deliver precise temperature control, ensuring repeatability and quality in your processes. Whether you're in research, production, or quality control, our deep customization capabilities can help you achieve reliable outcomes and maximize efficiency.

Don't let temperature variability hold you back—contact us today to discuss how our furnaces can transform your material processing and drive your success!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab