At its core, the difference between a tubular furnace and a muffle furnace comes down to geometry and its impact on sample processing. A muffle furnace is a chamber furnace, like a high-temperature box, designed for heating static objects in batches. A tube furnace uses a cylindrical tube as its heating chamber, making it ideal for processing small samples, often under a tightly controlled flow of gas.

The choice is not about which furnace is "better," but which geometry best serves your process. Muffle furnaces are built for batch capacity, while tube furnaces are built for atmospheric control and processing smaller, continuous-flow, or elongated samples.

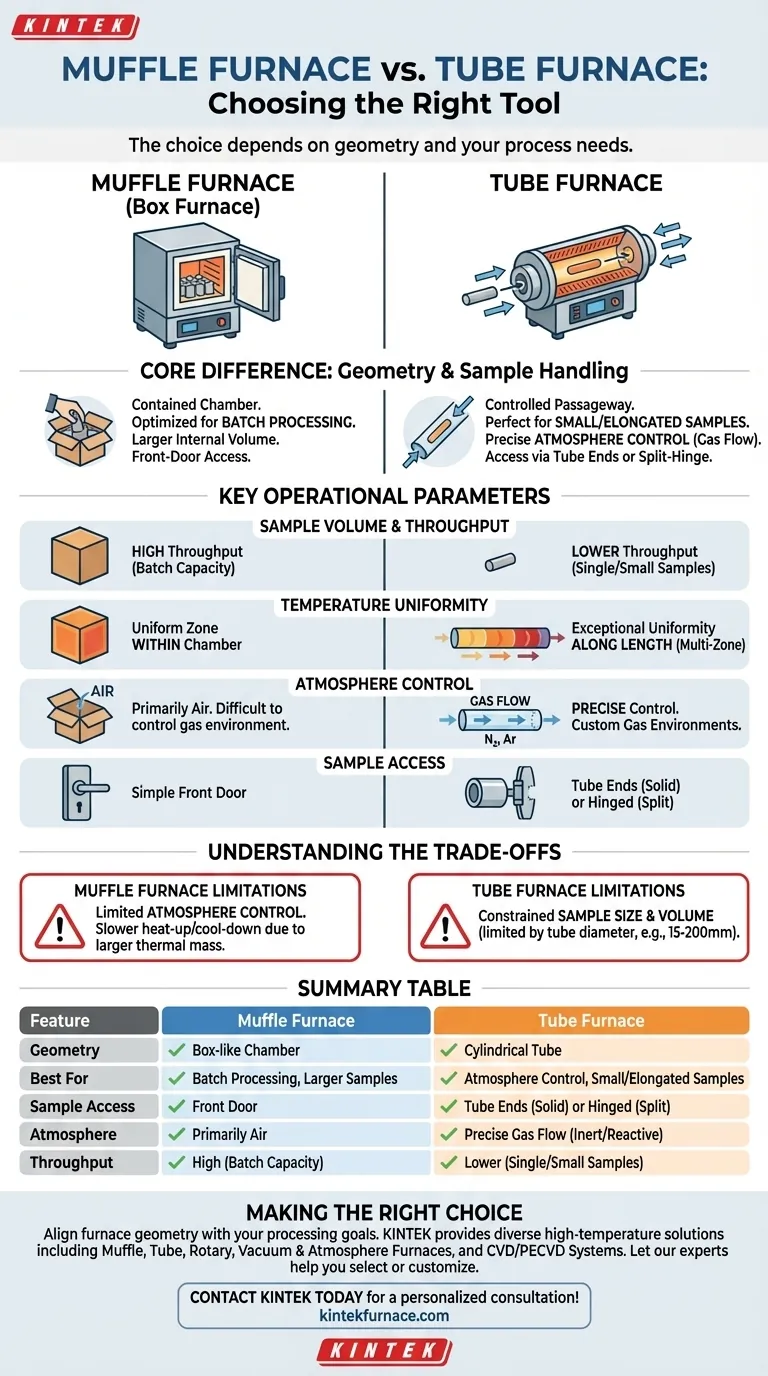

The Core Difference: Geometry and Sample Handling

The fundamental distinction between these two furnaces is their physical shape. This single factor dictates how you can load samples, the size of those samples, and how you can control the environment around them.

The Muffle Furnace: A Contained Chamber

A muffle furnace, also known as a box furnace, functions like a highly precise, high-temperature oven. It features a sealed chamber (the "muffle") that isolates the sample from the heating elements.

This design is optimized for batch processing. You open a door, place one or more objects inside the chamber, close the door, and run a heating cycle. They typically have a larger internal volume compared to tube furnaces.

The Tube Furnace: A Controlled Passageway

A tube furnace uses a long, cylindrical tube, often made of ceramic or quartz, as its heating chamber. The heating elements surround this tube.

This geometry is perfect for processing small or elongated samples. It is also exceptionally well-suited for applications requiring precise atmosphere control, as gases can be flowed directly through the tube and over the sample in a controlled, laminar fashion.

How Samples Are Accessed

In a muffle furnace, access is simple: you open a front-facing door.

In a tube furnace, samples are loaded into the tube. Solid tube furnaces require you to insert the sample from the ends, often using a push rod. Split-tube furnaces are hinged and can be opened along their length, allowing you to place the sample directly into the heating zone.

Comparing Key Operational Parameters

Beyond geometry, the two furnace types excel in different operational areas. Understanding these will help you match the right tool to your specific scientific or industrial goal.

Sample Volume and Throughput

A muffle furnace is the clear choice for larger samples or processing many smaller samples simultaneously in a single batch. Their larger chamber volume directly translates to higher throughput for static heating processes.

A tube furnace, by its nature, has a very small sample capacity. It is designed for processing individual, small samples with high precision.

Temperature Uniformity

Both furnaces can achieve excellent temperature stability. However, their uniformity differs. A muffle furnace provides a zone of uniform temperature within its box-like chamber.

A multi-zone tube furnace, particularly a three-zone model, offers exceptional temperature uniformity along the length of the tube. This is critical for processes like crystal growth or chemical vapor deposition where a consistent temperature profile over a specific length is required.

Atmosphere Control

This is a critical point of differentiation. A standard muffle furnace heats a sample in air. While the muffle isolates the sample from heating element contamination, it does not inherently control the gaseous environment.

A tube furnace is naturally designed for atmosphere control. Its tube geometry makes it simple to seal the ends and introduce a specific gas (like nitrogen or argon) or even a reactive gas mixture, creating a custom processing environment. For processes where atmospheric contamination is a concern, a tube furnace is superior.

Understanding the Trade-offs

Neither furnace is a universal solution. Choosing one involves accepting a set of limitations based on its design.

Muffle Furnace Limitations

The primary trade-off is atmosphere control. Creating a controlled gas environment in a muffle furnace is possible but often requires complex and expensive modifications. Their larger thermal mass can also mean they take longer to heat up and cool down compared to smaller tube furnaces.

Tube Furnace Limitations

The most significant limitation is sample size and volume. You are constrained by the diameter of the tube, which typically ranges from just 15 mm to 200 mm. This makes them unsuitable for bulk processing or heating large, non-uniform objects.

Making the Right Choice for Your Application

Select your furnace based on the demands of your process, not on a perceived superiority of one type over another.

- If your primary focus is batch processing or heating larger, static objects: The muffle furnace's chamber design is the correct choice.

- If your primary focus is precise atmosphere control or processing small samples with a flowing gas: The tube furnace is purpose-built for this task.

- If your primary focus is achieving the highest temperature uniformity over a specific length: A multi-zone tube furnace offers the best performance.

- If your primary focus is completely eliminating atmospheric gases for sensitive materials: Neither is ideal; you need to investigate a vacuum furnace.

Ultimately, aligning the furnace's inherent geometry with your processing goals is the key to a successful outcome.

Summary Table:

| Feature | Muffle Furnace | Tube Furnace |

|---|---|---|

| Geometry | Box-like Chamber | Cylindrical Tube |

| Best For | Batch Processing, Larger Samples | Atmosphere Control, Small/Elongated Samples |

| Sample Access | Front Door | Tube Ends (Solid) or Hinged (Split) |

| Atmosphere | Primarily Air | Precise Gas Flow (Inert/Reactive) |

| Throughput | High (Batch Capacity) | Lower (Single/Small Samples) |

Still Unsure Which Furnace is Right for Your Application?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Let our experts help you select or customize the perfect furnace for your needs. Contact KINTEL today for a personalized consultation!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis