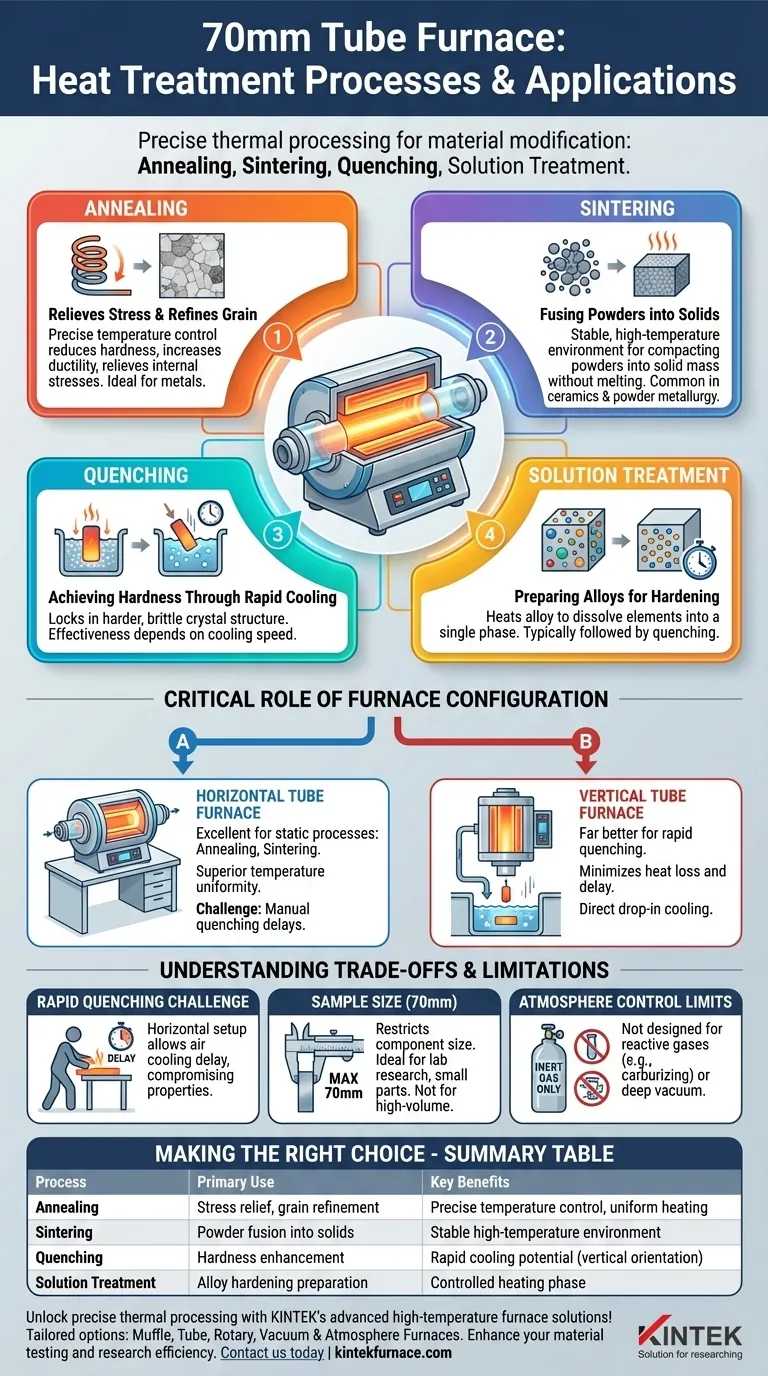

At its core, a 70mm tube furnace is a versatile tool for precise thermal processing of materials. It is most commonly used for heat treatments like annealing, sintering, and certain types of quenching and solution treatment. The primary goal of these processes is to modify a material's microstructure to achieve specific mechanical properties, such as increased hardness or reduced internal stress.

While a tube furnace offers exceptional temperature precision for many heat treatments, its effectiveness for specific tasks is dictated by its configuration. Understanding the difference between horizontal and vertical orientations, as well as the limits of its atmosphere control, is critical for achieving desired results.

Understanding the Core Processes

A 70mm tube furnace excels at processes that rely on highly uniform and stable temperature environments. Each process alters the material in a distinct way.

Annealing: Relieving Stress and Refining Grain

Annealing involves heating a material to a specific temperature and holding it there before cooling it slowly. This process reduces hardness, increases ductility, and relieves internal stresses that may have developed during manufacturing. The precise temperature control of a tube furnace makes it ideal for this task.

Sintering: Fusing Powders into Solids

Sintering is the process of compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction. Tube furnaces provide the stable, high-temperature environment needed to fuse material powders together, which is common in ceramics and powder metallurgy.

Quenching: Achieving Hardness Through Rapid Cooling

Quenching involves rapidly cooling a metal from a high temperature to lock in a harder, more brittle crystal structure. While a tube furnace can heat the material for quenching, the effectiveness of the process depends heavily on how quickly the material can be moved to a cooling medium (like oil or water).

Solution Treatment: Preparing Alloys for Hardening

This process involves heating an alloy to dissolve its constituent elements into a single, solid-phase solution. It is typically followed by rapid cooling (quenching) to trap this structure. Like quenching, the heating phase is well-controlled in a tube furnace, but the success of the overall treatment depends on the quenching step.

The Critical Role of Furnace Configuration

Not all 70mm tube furnaces are the same. Its physical orientation and atmospheric capabilities define what it can realistically accomplish.

Temperature Uniformity and Control

The key benefit of any tube furnace is its ability to maintain a highly uniform heated zone. This ensures that the entire sample receives the same thermal treatment, leading to consistent and repeatable material properties.

Atmosphere Control

Most tube furnaces allow for the introduction of an inert gas (like argon or nitrogen) to create a controlled atmosphere. This is crucial for preventing oxidation and other unwanted chemical reactions on the material's surface at high temperatures. However, this is distinct from the capabilities of a true vacuum furnace, which can perform specialized treatments like vacuum brazing or nitriding.

The Horizontal vs. Vertical Distinction

The orientation of the furnace tube is a major factor. A standard horizontal tube furnace is excellent for static processes like annealing and sintering. However, a vertical tube furnace is far better suited for processes requiring rapid quenching, as the sample can be dropped directly from the hot zone into a quenching bath below, minimizing heat loss and delay.

Understanding the Trade-offs and Limitations

To use a tube furnace effectively, you must be aware of its inherent constraints.

The Challenge of Rapid Quenching

In a horizontal tube furnace, quenching requires manually removing the hot sample and transferring it to a cooling medium. This delay, however brief, allows the sample to cool in the air, which can compromise the final properties and make the process less repeatable than in a dedicated vertical setup.

Sample Size and Throughput

The 70mm diameter restricts the size of the components that can be treated. This form factor is ideal for laboratory-scale research, material testing, and processing small parts, but it is not suited for high-volume production.

Process Atmosphere Limitations

While a tube furnace can operate with an inert gas atmosphere, it is not designed for processes requiring reactive gases (like carburizing) or a deep vacuum. These specialized surface treatments demand furnaces built specifically for those environments.

Making the Right Choice for Your Goal

Select your process based on an objective understanding of your equipment's capabilities.

- If your primary focus is annealing or sintering: A standard horizontal tube furnace is an excellent choice due to its superior temperature uniformity and control.

- If your primary focus is high-performance quenching: A vertical tube furnace configuration is necessary for achieving the rapid, controlled cooling required for optimal hardness.

- If your primary focus is surface modification (e.g., nitriding or carburizing): You will need a specialized vacuum or reactive gas furnace, as a standard tube furnace is not designed for these processes.

Understanding these capabilities and constraints is the first step toward achieving precise, repeatable results in your material processing.

Summary Table:

| Process | Primary Use | Key Benefits |

|---|---|---|

| Annealing | Stress relief, grain refinement | Precise temperature control, uniform heating |

| Sintering | Powder fusion into solids | Stable high-temperature environment |

| Quenching | Hardness enhancement | Rapid cooling potential (vertical orientation) |

| Solution Treatment | Alloy hardening preparation | Controlled heating phase |

Unlock precise thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met. Contact us today to enhance your material testing and research efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety