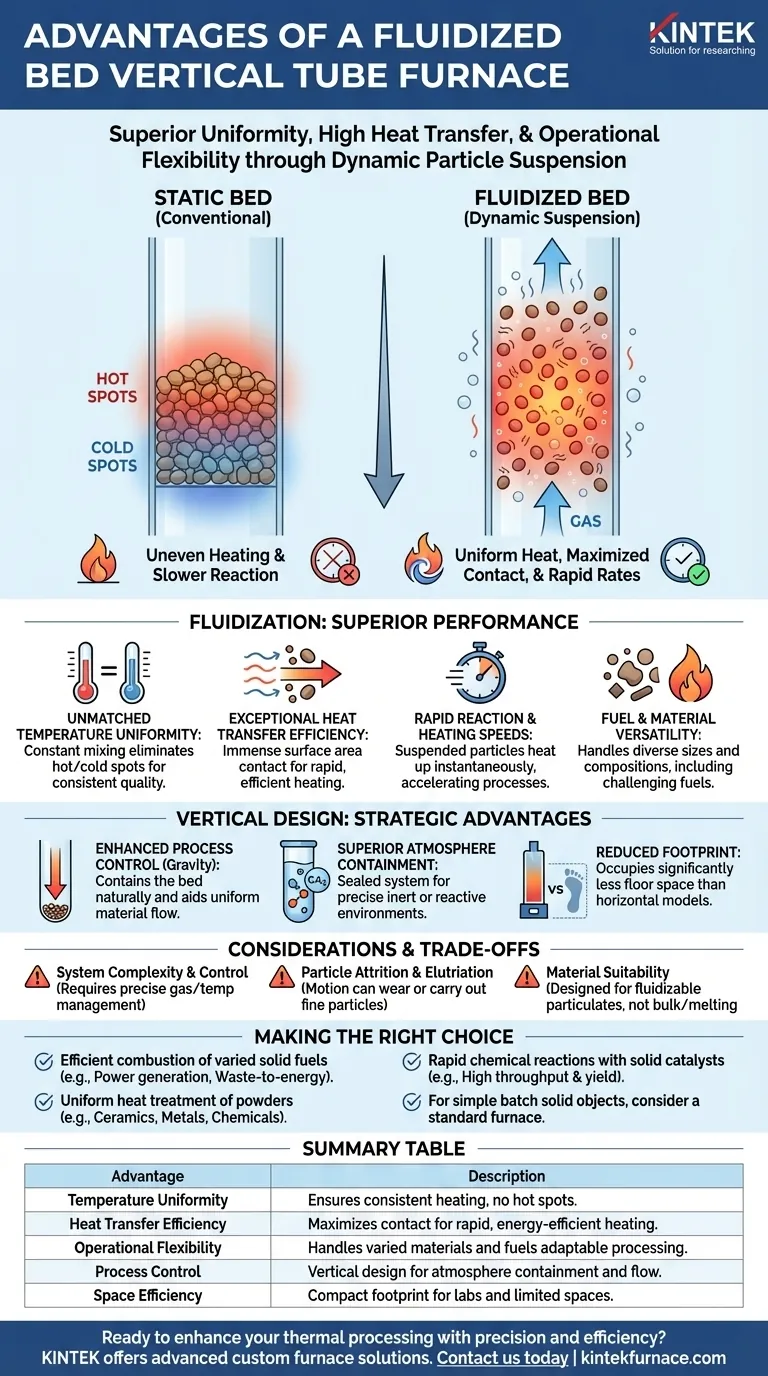

In short, a fluidized bed vertical tube furnace offers superior temperature uniformity, high heat transfer efficiency, and exceptional operational flexibility. It achieves this by combining the controlled environment of a vertical tube furnace with the unique properties of a fluidized bed, where solid particles are suspended in an upward-flowing gas, behaving like a fluid.

The core challenge in many thermal processes is achieving uniform, efficient, and rapid heating of particulate materials. A fluidized bed vertical tube furnace directly solves this by creating a dynamic system where every particle is constantly moving and fully exposed to the processing environment, eliminating hot spots and maximizing reaction rates.

How Fluidized Bed Technology Delivers Superior Performance

The primary advantages of this furnace stem from the core principle of fluidization. By forcing a gas upward through a bed of solid particles, the particles become suspended and behave like a liquid. This dynamic state is the source of its key benefits.

Unmatched Temperature Uniformity

The constant, vigorous mixing of particles within the fluidized bed ensures an exceptionally uniform temperature distribution. This eliminates the hot and cold spots common in static furnace designs, leading to highly consistent product quality and predictable reaction outcomes.

Exceptional Heat Transfer Efficiency

Fluidization creates an enormous surface area for contact between the gas and the solid particles. This maximized contact results in extremely high heat transfer rates, allowing the material to reach the desired temperature quickly and efficiently.

Rapid Reaction and Heating Speeds

Because individual particles are suspended and surrounded by the heating gas, they heat up almost instantaneously. For chemical processes, this same principle dramatically accelerates reaction speeds by ensuring intimate contact between reactant gases and solid catalysts or materials.

Fuel and Material Versatility

The turbulent nature of the fluidized bed allows it to handle a wide range of solid fuels and materials, including those with varying sizes and compositions. This makes it highly adaptable for combusting challenging fuels like biomass or low-grade coal, or for processing diverse powders.

The Strategic Advantages of the Vertical Design

The "vertical tube" aspect of the furnace provides its own set of distinct benefits that complement the fluidized bed technology.

Enhanced Process Control with Gravity

The vertical orientation uses gravity to its advantage. It helps contain the fluidized bed naturally and can assist in ensuring a more uniform flow of materials through the system, especially in continuous-feed operations.

Superior Atmosphere Containment

The process takes place within a sealed tube, which allows for precise control over the atmosphere. This is critical for applications that require inert (e.g., nitrogen, argon) or reactive gas environments, preventing contamination and unwanted side reactions.

Reduced Footprint

Compared to horizontal furnaces with similar capacities, vertical tube furnaces occupy significantly less floor space. This makes them an ideal choice for laboratories and manufacturing facilities where space is at a premium.

Understanding the Trade-offs and Considerations

While powerful, this technology is not a universal solution. A clear understanding of its operational requirements is essential for success.

System Complexity and Control

Achieving and maintaining a stable fluidized bed requires precise control over gas flow rates, temperature, and pressure. These systems are more complex to operate than simple static furnaces and require a deeper level of process understanding.

Particle Attrition and Elutriation

The constant motion of particles can cause them to break down or wear away, a process known as attrition. Furthermore, very fine particles can be carried out of the furnace with the exhaust gas (elutriation), often requiring downstream equipment like cyclones or filters to capture them.

Material Suitability

This technology is specifically designed for solid particulate materials that can be fluidized. It is not suitable for processing large, single objects, bulk solids that don't flow, or materials that would melt and clump together at operating temperatures, thereby disrupting the fluidization.

Making the Right Choice for Your Application

To determine if this furnace is the correct tool, you must align its strengths with your primary processing goal.

- If your primary focus is efficient combustion of varied solid fuels: The furnace's high efficiency and fuel flexibility make it ideal for power generation or waste-to-energy applications.

- If your primary focus is uniform heat treatment of powders: This technology guarantees that every particle experiences a near-identical thermal history, which is critical for producing high-quality ceramics, metals, or chemicals.

- If your primary focus is rapid chemical reactions with solid catalysts: The immense surface area and contact efficiency dramatically accelerate gas-solid reactions, increasing throughput and yield.

- If your primary focus is simple batch processing of solid objects: A standard vertical or horizontal tube furnace without the fluidized bed component will likely be a simpler and more cost-effective solution.

By understanding the core principles of fluidization and vertical design, you can confidently determine if this advanced furnace technology aligns with your specific processing goals.

Summary Table:

| Advantage | Description |

|---|---|

| Temperature Uniformity | Ensures consistent heating with no hot spots for reliable results. |

| Heat Transfer Efficiency | Maximizes gas-solid contact for rapid and energy-efficient heating. |

| Operational Flexibility | Handles diverse materials and fuels with adaptable processing. |

| Process Control | Uses vertical design for better atmosphere containment and flow. |

| Space Efficiency | Compact footprint ideal for labs and facilities with limited space. |

Ready to enhance your thermal processing with precision and efficiency?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements.

Whether you're working with powders, catalysts, or varied solid fuels, our fluidized bed vertical tube furnaces can deliver unmatched performance. Contact us today to discuss how we can optimize your laboratory processes and achieve superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety