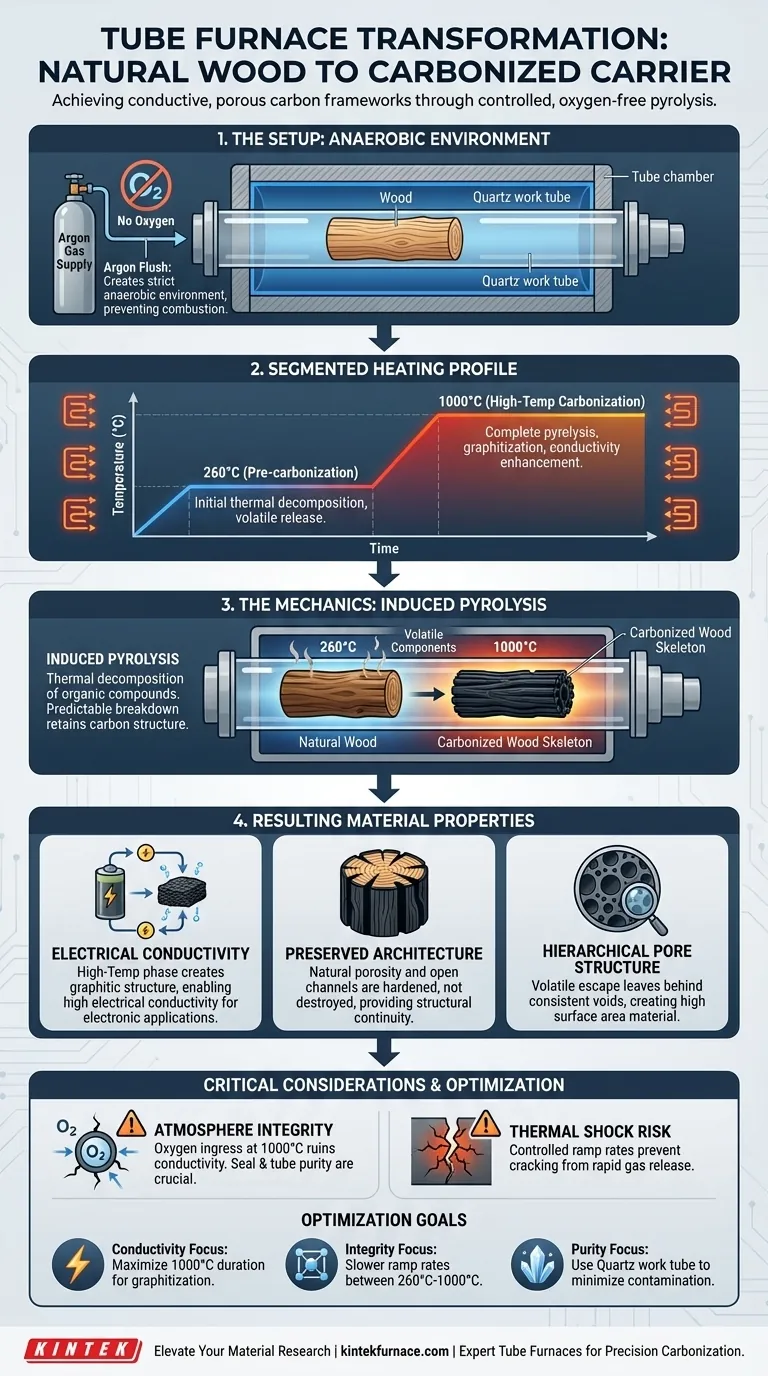

The transformation of natural wood into a Carbonized Wood carrier relies entirely on the tube furnace's ability to maintain a controlled, oxygen-free environment during distinct heating stages. By subjecting the wood to segmented heating under argon gas protection—specifically pre-carbonization at 260°C followed by high-temperature carbonization at 1000°C—the furnace facilitates precise pyrolysis. This process strips away volatile components, leaving behind a highly conductive, porous biomass carbon skeleton.

A tube furnace acts as a precision reactor, using inert atmospheres and programmable temperature gradients to convert organic wood structures into conductive carbon frameworks without destroying their natural porosity.

The Mechanics of Carbonization

Creating an Anaerobic Environment

The most critical function of the tube furnace in this process is isolation. Natural wood contains carbon, but heating it in the presence of air simply results in combustion (ash).

By sealing the wood within a work tube and flushing it with argon gas, the furnace creates a strict anaerobic environment. This ensures that the application of heat triggers chemical transformation rather than burning.

Segmented Heating Profiles

Carbonization is not achieved by simply blasting the material with heat; it requires a specific "recipe" or program. The tube furnace’s digital controller allows for segmented heating.

The process begins with pre-carbonization at 260°C. Once this stage is complete, the furnace ramps the temperature up to 1000°C for the high-temperature carbonization phase.

Inducing Pyrolysis

The heat supplied by the elements surrounding the tube induces pyrolysis. This is the thermal decomposition of the wood's primary components, such as cellulose.

Because the heat is uniform and the environment is inert, the organic compounds break down predictably. This removes volatile matter while retaining the carbon structure.

Resulting Material Properties

Electrical Conductivity

The high-temperature phase (1000°C) is essential for altering the electrical properties of the material.

While natural wood is an insulator, the carbonized skeleton produced by the furnace exhibits high electrical conductivity. This transformation allows the wood to serve as an effective carrier in electronic or electrochemical applications.

Preservation of Architecture

Unlike crushing or chemical pulping, the tube furnace preserves the wood's natural architecture.

The resulting biomass carbon skeleton retains open channels. These natural pathways are hardened rather than destroyed, providing structural continuity.

Hierarchical Pore Structure

The pyrolysis process leaves behind a hierarchical pore structure.

As volatile components exit the wood during heating, they leave voids behind. The precision of the tube furnace ensures these pores are formed consistently, creating a high surface area material.

Critical Operational Considerations

Managing Atmosphere Integrity

The success of the process hinges entirely on the purity of the inert atmosphere.

If the tube material (e.g., quartz or alumina) is compromised or the seals fail, oxygen will enter the chamber. Even a small amount of oxygen at 1000°C will degrade the carbon skeleton and ruin the conductivity.

Thermal Uniformity vs. Shock

While tube furnaces are designed for uniform heating, the rate of temperature change (ramp rate) is a trade-off.

Heating the sample too quickly can cause thermal shock, potentially cracking the wood structure before carbonization is complete. The heating elements outside the tube provide even distribution, but the user must program a ramp rate that allows the wood to release gases without structural failure.

Optimizing the Carbonization Process

To achieve the best results when converting natural wood, you must tailor the furnace parameters to your specific performance goals.

- If your primary focus is Electrical Conductivity: Ensure your program maintains the 1000°C stage for a sufficient duration to maximize graphitization.

- If your primary focus is Structural Integrity: Use a slower ramp rate between the 260°C and 1000°C stages to prevent thermal shock from rapid gas release.

- If your primary focus is Purity: Utilize a quartz work tube to minimize potential contamination from the furnace hardware itself.

The tube furnace is not merely a heating device; it is the tool that determines whether your wood becomes a pile of ash or a sophisticated, conductive carbon carrier.

Summary Table:

| Process Stage | Temperature | Primary Function | Outcome |

|---|---|---|---|

| Atmosphere Purge | Ambient | Argon gas flushing | Creates a strict anaerobic environment |

| Pre-carbonization | 260°C | Initial thermal decomposition | Prepares wood for high-heat pyrolysis |

| High-Temp Carbonization | 1000°C | Complete pyrolysis & carbonization | Creates high electrical conductivity |

| Pore Formation | Constant | Volatile component removal | Develops a hierarchical pore structure |

Elevate Your Material Research with KINTEK

Transform organic precursors into advanced carbon carriers with precision and reliability. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems.

Our lab high-temperature furnaces are fully customizable to meet your unique research needs, ensuring perfect thermal uniformity and atmosphere control for every project.

Ready to optimize your carbonization process? Contact our technical experts today to find the ideal furnace solution for your laboratory.

Visual Guide

References

- Yuan Ma, Jie Gao. Boosting electrocatalytic generation of FDCA and H2 from 2,5-furanedimethanol solution by carbonized wood supported Fe-CoP nanoleaves. DOI: 10.1007/s42773-024-00380-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a high-temperature tube furnace play in converting MXene derivatives into N-TiO2@NC? Unlock Precision Synthesis

- What is a vacuum tube furnace? Essential for High-Purity Material Processing

- What safety precautions should be taken when operating a horizontal electric furnace? Ensure Operator and Equipment Protection

- How does a tube furnace differ from a muffle furnace? Choose the Right Furnace for Your Lab

- What role does a high-temperature tube furnace play in the calcination of superconducting ceramics? Expert Insights

- What are the main features and functions of a laboratory tube furnace? Unlock Precise High-Temp Control for Your Lab

- What role do multi zone tube furnaces play in new energy research? Unlock Precise Thermal Control for Innovation

- What role does a laboratory tube furnace play in the carbonization process of moxa floss? Expert Guide to Biomass Synthesis