At its core, the difference between a tube furnace and a muffle furnace is defined by the shape and accessibility of the heating chamber. A tube furnace utilizes a narrow, cylindrical tube to create a highly controlled environment, while a muffle furnace employs a larger, box-shaped chamber designed for capacity and versatility. This fundamental design difference dictates which furnace is best suited for a specific scientific or industrial process.

The decision is not about which furnace is "better," but which geometry best serves your purpose. Choose a tube furnace for precision control over atmosphere and temperature, especially for smaller samples. Choose a muffle furnace for processing larger, bulkier, or numerous samples where chamber volume is the priority.

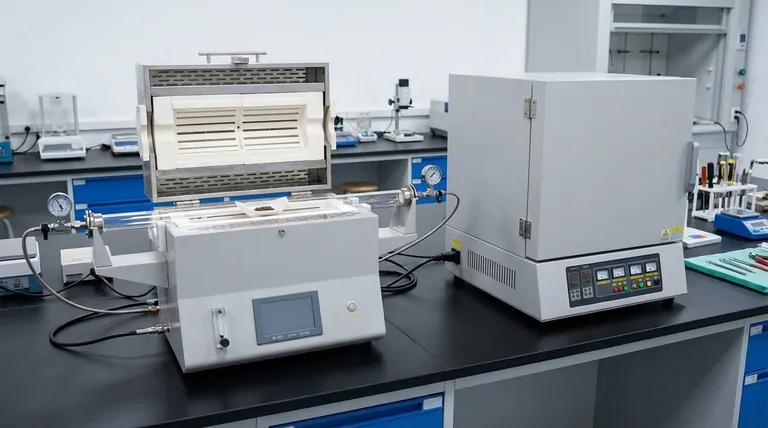

The Core Design Distinction: Geometry Defines Function

The name of each furnace reveals its fundamental structure. This structure is the most important factor in determining its ideal application.

The Muffle (or Box) Furnace: Maximizing Volume

A muffle furnace contains a heating chamber that is a "muffle"—an enclosure that isolates the sample from the heating elements. This design provides clean, indirect heat within a large, box-like space.

This larger internal capacity is its primary advantage. It is built to accommodate irregularly shaped objects, large components, or multiple samples arranged on trays for batch processing.

The Tube Furnace: Engineering for Control

A tube furnace's heating chamber is a long cylinder, typically made of ceramic or quartz. The sample is placed inside this tube.

This cylindrical geometry is inherently ideal for creating a highly uniform processing environment. The defined, narrow path allows for precise control over gas flow and temperature gradients along its length, which is critical for many sensitive synthesis and analysis procedures.

How Design Impacts Key Operational Parameters

The physical shape of each furnace directly translates into distinct operational advantages and disadvantages for atmosphere, temperature, and sample handling.

Atmosphere Control and Purity

Tube furnaces excel at atmosphere control. The exposed ends of the tube make it simple to connect gas lines and vacuum pumps. The confined, linear space ensures that inert or reactive gases flow uniformly over the sample, effectively purging the environment.

Muffle furnaces can also be equipped with gas ports for atmosphere control. However, achieving the same level of flow uniformity and purity within a large, open box is significantly more challenging and less efficient.

Temperature Uniformity

Multi-zone tube furnaces offer exceptional temperature uniformity. By dividing the heating length into multiple (often three) controllable zones, they can create an extended, stable, and flat temperature profile. This is crucial for processes like crystal growth or chemical vapor deposition.

While a muffle furnace provides good general temperature uniformity within its chamber, it is more susceptible to temperature drops near the door. It cannot match the precise, linear temperature profile of a dedicated multi-zone tube furnace.

Sample Size and Throughput

This is the muffle furnace's defining strength. If your sample physically does not fit within the 15 mm to 200 mm diameter of a typical process tube, the muffle furnace is your only option. Its large chamber is ideal for annealing, ashing, or heat-treating bulky items.

Tube furnaces are limited to smaller samples that can fit within the tube's diameter. They are better suited for processing powders, small components, or for continuous processes where a material is passed through the heated zone.

Understanding the Trade-offs

Choosing a furnace means accepting a set of compromises. Understanding these trade-offs is key to avoiding costly purchasing mistakes.

The Tube Furnace Compromise: Size for Precision

The primary limitation of a tube furnace is its restrictive geometry. The small diameter limits sample size and shape. Loading samples can also be more difficult, although split tube furnaces, which hinge open for direct access to the chamber, help mitigate this issue.

The Muffle Furnace Compromise: Control for Capacity

The benefit of a large chamber comes at the cost of precision. It is inherently less energy-efficient to heat a large box for a small sample, and achieving a truly pure, uniform gas atmosphere is difficult. Heating and cooling cycles may also be slower compared to a more compact tube furnace.

Making the Right Choice for Your Process

Your specific application, not a general sense of superiority, should guide your decision. Analyze your needs based on the following criteria.

- If your primary focus is precise atmosphere control or temperature uniformity over a defined length: Choose a tube furnace, especially a multi-zone model for the most demanding applications.

- If your primary focus is processing large, bulky, or irregularly shaped samples: Choose a muffle furnace for its superior chamber volume and accessibility.

- If your primary focus is high-purity, oxygen-free processing of smaller samples: A vacuum tube furnace is the established standard for this task.

- If your primary focus is batch processing numerous small items or general-purpose heat treatment: A muffle furnace offers the most flexibility for loading and sample versatility.

Ultimately, selecting the correct furnace requires a clear understanding of your sample's geometry and your process's sensitivity to atmosphere and temperature.

Summary Table:

| Feature | Tube Furnace | Muffle Furnace |

|---|---|---|

| Chamber Shape | Cylindrical tube | Box-shaped chamber |

| Best For | Precise atmosphere/temperature control | Large, bulky, or batch samples |

| Sample Size | Smaller samples (fits tube diameter) | Larger, irregular samples |

| Atmosphere Control | Excellent (uniform gas flow) | Good, but less precise |

| Temperature Uniformity | High (especially multi-zone) | Good, but may have hot/cold spots |

Struggling to choose between a tube and muffle furnace for your lab? At KINTEK, we specialize in providing advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements, whether you need precise atmosphere control or large sample capacity. Don't compromise on performance—contact us today to discuss how we can enhance your laboratory efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents