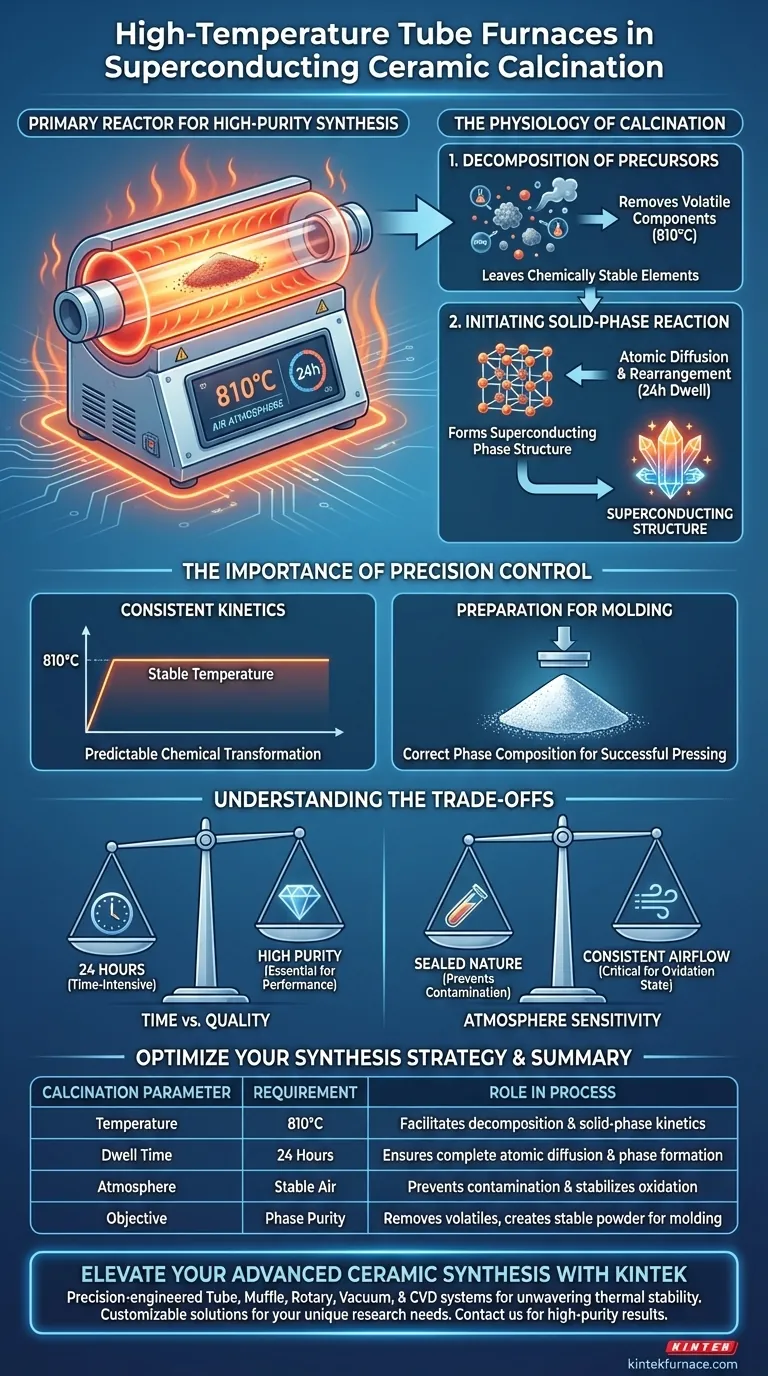

The high-temperature tube furnace acts as the primary reactor for the synthesis of superconducting ceramics. It provides a highly stable thermal environment—specifically maintaining an air atmosphere at 810 degrees Celsius for 24 hours—to facilitate the decomposition of precursor materials and drive the initial solid-phase reaction required to form the superconducting structure.

The furnace ensures consistent reaction kinetics by removing volatile components and stabilizing the material’s phase, establishing the necessary chemical foundation for subsequent molding and sintering processes.

The Physiology of Calcination

Decomposition of Precursors

The primary function of the tube furnace during this stage is to purify the raw materials. The controlled heat breaks down the chemical precursors, specifically targeting volatile components.

By maintaining the temperature at 810°C, the furnace forces these unstable elements to decompose and exit the material. This leaves behind only the chemically stable elements required for the superconducting structure.

Initiating the Solid-Phase Reaction

Once volatiles are removed, the furnace facilitates a solid-phase reaction. This is where the actual chemistry of the superconductor begins to take shape.

The 24-hour duration is critical here. It allows sufficient time for the atoms within the solid mixture to diffuse and rearrange themselves, initiating the formation of the specific superconducting phase structure.

The Importance of Precision Control

Establishing Consistent Kinetics

The definition of a high-quality superconducting ceramic is uniformity. The tube furnace’s ability to provide stable temperature control is paramount.

If the temperature fluctuates, the reaction kinetics become unpredictable. By locking the thermal environment at 810°C, the furnace ensures that the chemical transformation occurs at a steady, predictable rate throughout the entire batch.

Preparation for Molding

Calcination is not the final step; it is the foundation. The output of the tube furnace is a powder that must be chemically ready for the next stage: molding.

If the calcination is incomplete or inconsistent, the material will fail during the subsequent molding or sintering phases. The tube furnace ensures the powder has the correct phase composition to be pressed and shaped successfully.

Understanding the Trade-offs

The Constraint of Time

The calcination process described is time-intensive. Dedicating 24 hours to a single thermal cycle places a limit on throughput.

However, this time investment is non-negotiable for high-performance ceramics. Rushing the heating profile or shortening the dwell time often results in incomplete reactions, retaining volatile impurities that degrade the final superconducting properties.

Atmosphere Sensitivity

While this specific process utilizes a standard air atmosphere, tube furnaces are distinct from other heating methods (like open firing) because of their sealed nature.

This design prevents external contaminants from entering the reaction zone. However, it also means the operator must ensure the tube is clean and the airflow is consistent. Any variation in the atmosphere can alter the oxidation state of the material, similar to how annealing processes rely on precise oxygen replenishment to fix defects.

Optimizing Your Synthesis Strategy

Making the Right Choice for Your Goal

- If your primary focus is Phase Purity: Ensure your furnace can maintain the strict 810°C setpoint without fluctuation to guarantee a complete solid-phase reaction.

- If your primary focus is Material Workability: Prioritize the full 24-hour dwell time to fully decompose volatiles, ensuring the powder is chemically stable for molding.

Success in fabricating superconducting ceramics relies less on the peak temperature itself, and more on the unwavering stability of the environment over time.

Summary Table:

| Calcination Parameter | Requirement | Role in Process |

|---|---|---|

| Temperature | 810°C | Facilitates decomposition and solid-phase reaction kinetics |

| Dwell Time | 24 Hours | Ensures complete atomic diffusion and phase formation |

| Atmosphere | Stable Air | Prevents contamination and stabilizes material oxidation |

| Objective | Phase Purity | Removes volatiles to create stable powder for molding |

Elevate Your Advanced Ceramic Synthesis with KINTEK

Precision is the heartbeat of superconducting research. At KINTEK, we understand that a deviation of just a few degrees can compromise your entire batch. Backed by expert R&D and manufacturing, we provide high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to deliver the unwavering thermal stability your lab requires.

Whether you need custom dimensions for specific tube lengths or advanced atmosphere control for sensitive materials, our lab high-temp furnaces are fully customizable to your unique needs. Contact us today to find the perfect thermal solution for your research and ensure consistent, high-purity results in every calcination cycle.

Visual Guide

References

- Bilal A. Omar, Abdulsalam S. Baqi. Effects of La2O3 Nanoparticles on the Superconducting Behavior of Bi1.60 Ag0.40 Sr1.9 Ba0.1 Ca2 Cu3 O10+δ Ceramics. DOI: 10.59324/stss.2025.2(6).08

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What challenges does the 70mm tube furnace market face? Overcome Technical, Quality, and Safety Hurdles

- How does the temperature controller function in a 70mm tube furnace? Achieve Precise Thermal Control for Your Lab

- How does an industrial tube furnace facilitate the pack cementation process? Master Precision Diffusion Coatings

- How do furnace chamber working conditions influence the choice of a tube furnace? Optimize Performance and Cost

- What are the advantages of using industrial aluminum profiles for tube furnaces? Achieve Modular Lab Efficiency

- What is a three zone furnace? The Key to Superior Temperature Uniformity

- Why is it critical to precisely control the heating rate at 3°C/min for Ni/NiO@GF electrodes? Achieve Structural Integrity

- What physical conditions does a tube furnace provide for biomass pyrolysis? Master Thermal Control for Bio-Energy