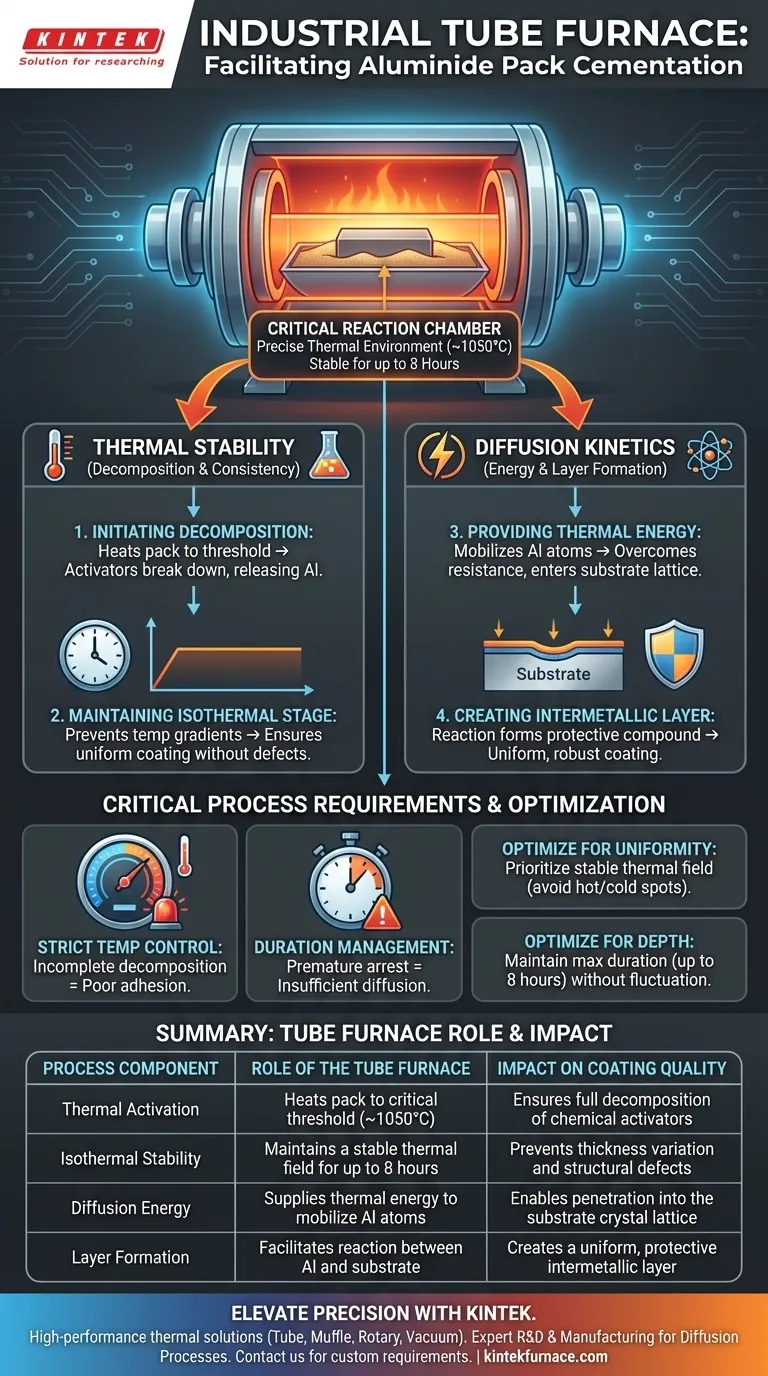

An industrial tube furnace serves as the critical reaction chamber for pack cementation, providing the precise thermal environment required to deposit protective coatings. It facilitates this process by maintaining a stable temperature, typically around 1050°C, which triggers the chemical decomposition of activators and supplies the energy needed to drive aluminum atoms into a substrate.

The tube furnace ensures coating quality by sustaining a strictly controlled isothermal environment. This prolonged heat exposure is the primary driver that breaks down chemical agents and forces aluminum diffusion, resulting in a uniform intermetallic layer.

The Role of Thermal Stability

Initiating Chemical Decomposition

The primary function of the furnace is to heat the powder pack to a critical reaction threshold.

At specific high temperatures, the furnace ensures the effective decomposition of activators mixed within the pack. This chemical breakdown is the first step in releasing aluminum for deposition.

Maintaining the Isothermal Stage

Success in pack cementation relies on consistency over time, not just peak temperature.

The tube furnace is designed to hold a stable thermal field for prolonged periods, often lasting up to 8 hours. This stability prevents temperature gradients that could lead to uneven coating thickness or structural defects.

Driving Diffusion Kinetics

Providing Thermal Energy

Once the aluminum is released from the pack, it requires significant energy to penetrate the base material.

The furnace provides the necessary thermal energy to mobilize aluminum atoms. This heat allows the atoms to overcome physical resistance and migrate effectively into the crystal lattice of the substrate, such as molybdenum.

Creating the Intermetallic Layer

The ultimate goal of this thermal application is the formation of a new compound.

By maintaining high heat, the furnace enables the reaction between the diffusing aluminum and the substrate. This results in the formation of a uniform intermetallic compound layer, which provides the desired protective properties.

Critical Process Requirements

Strict Temperature Control

The effectiveness of the process is binary; it relies entirely on the precision of the furnace.

If the furnace cannot maintain a strictly controlled high-temperature environment (e.g., 1050°C), the activator decomposition may be incomplete. This leads to poor coating adhesion or insufficient protection.

Duration Management

The depth and quality of the coating are directly proportional to the time spent at temperature.

The furnace must operate reliably during prolonged isothermal stages. Cutting this time short, or experiencing fluctuations during the 8-hour cycle, will arrest the diffusion process prematurely.

Optimizing the Coating Strategy

If your primary focus is Coating Uniformity: Ensure your furnace calibration prioritizes a stable thermal field to prevent hot spots or cold zones within the tube.

If your primary focus is Diffusion Depth: Focus on the capability of the furnace to maintain the isothermal stage for the maximum required duration (up to 8 hours) without fluctuation.

Precision in heat application is the difference between a superficial layer and a robust, industrial-grade coating.

Summary Table:

| Process Component | Role of the Tube Furnace | Impact on Coating Quality |

|---|---|---|

| Thermal Activation | Heats pack to critical threshold (~1050°C) | Ensures full decomposition of chemical activators |

| Isothermal Stability | Maintains a stable thermal field for up to 8 hours | Prevents thickness variation and structural defects |

| Diffusion Energy | Supplies thermal energy to mobilize aluminum atoms | Enables penetration into the substrate crystal lattice |

| Layer Formation | Facilitates reaction between Al and substrate | Creates a uniform, protective intermetallic layer |

Elevate Your Coating Precision with KINTEK

Unlock superior material protection with KINTEK’s high-performance thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Tube, Muffle, Rotary, and Vacuum systems designed to meet the rigorous demands of pack cementation and diffusion processes.

Whether you require precise isothermal control for aluminide coatings or a fully customizable CVD system for unique research needs, our engineering team ensures your lab is equipped for excellence.

Ready to optimize your heat treatment results? Contact us today to discuss your custom furnace requirements.

Visual Guide

References

- Jurica Filipovic, Matthias Oechsner. Thermokinetic Modeling Approach for Aluminide Diffusion Coatings on Molybdenum Substrates. DOI: 10.1002/adem.202500293

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the difference between a tube furnace and a box furnace? Choose the Right Tool for Your Lab

- How is an electric tubular furnace defined and what are its main functions? Unlock Precision Heating for Your Lab

- What role does a tubular furnace play in converting precursors into microwave-absorbing Fe-CN@CoCN? Expert Insights

- What are the applications of an atmosphere tube furnace? Unlock Precise Material Processing

- How do horizontal furnaces support the ceramics industry? Boost Performance with Precision Heat Treatment

- What should be considered when purchasing a horizontal tube furnace? Key Factors for Your Thermal Process

- How does a horizontal tube furnace ensure experimental safety and accuracy during the thermal dehydrogenation of Ca(AlH4)2?

- What is the function of a tube furnace in pRF preparation? Optimize Carbonization & Conductivity