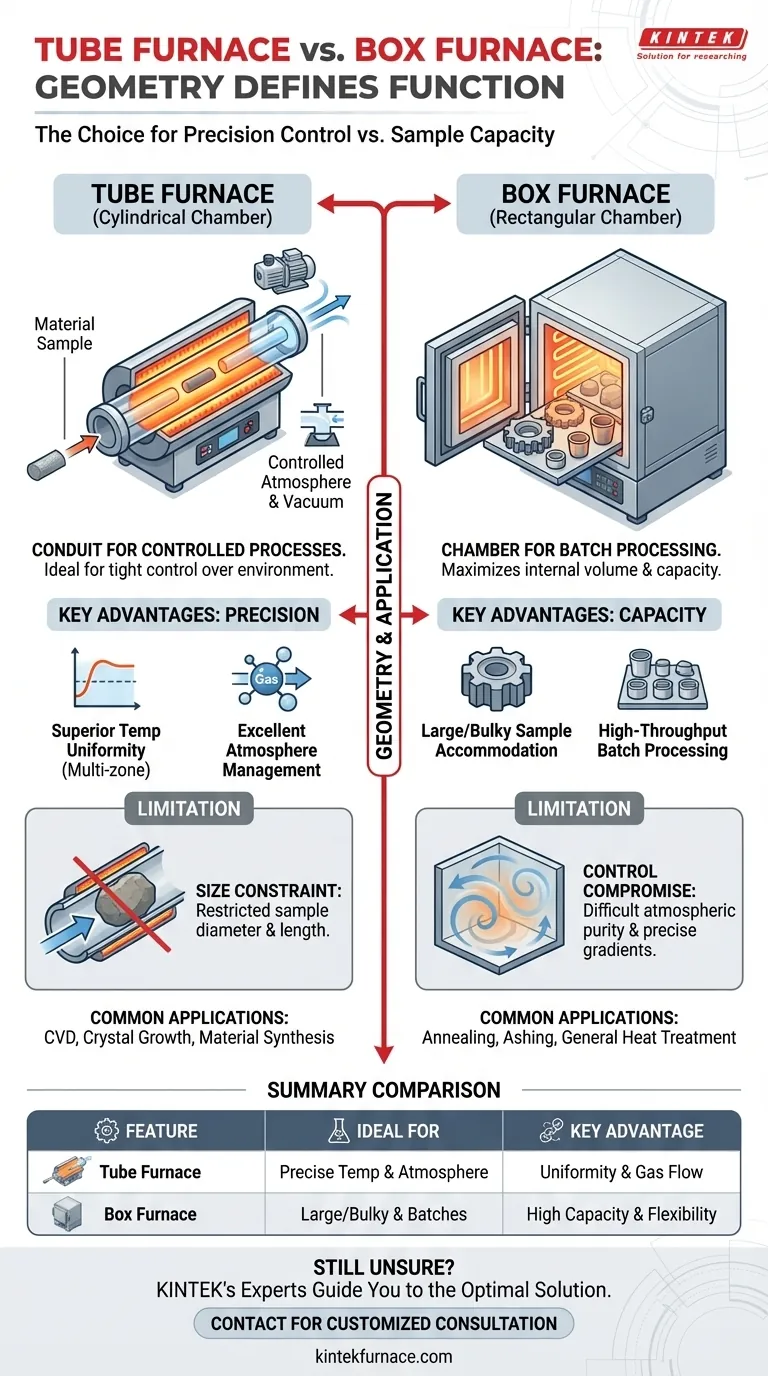

The fundamental difference between a tube furnace and a box furnace lies in the geometry of their heating chambers, which dictates their ideal applications. A tube furnace heats materials inside a long, narrow cylinder, offering exceptional process control, while a box furnace heats materials inside a larger, rectangular chamber, prioritizing sample size and batch capacity.

The choice is not about which furnace is better, but which tool is right for the job. Tube furnaces excel at precise control over temperature and atmosphere, whereas box furnaces are built for handling larger volumes and bulkier samples.

The Fundamental Design Difference: Geometry Defines Function

The shape of the furnace's heating chamber is the single most important factor that defines its strengths and weaknesses. This core design principle determines how a sample is heated and what kind of processes are possible.

The Tube Furnace: A Conduit for Controlled Processes

A tube furnace uses a cylindrical tube, typically made of ceramic or quartz, as its heating chamber. Materials are placed inside or passed through this tube.

This elongated design is uniquely suited for processes requiring tight control over the sample's environment. The exposed ends of the tube make it simple to create a sealed system for managing gas flow, enabling high-purity vacuum or inert atmosphere conditions.

The Box Furnace: A Chamber for Batch Processing

A box furnace, often called a muffle furnace, features a rectangular internal chamber. Samples are placed directly inside this sealed "box" for heating.

This design maximizes internal volume and capacity. It is the default choice for heating samples that are large, have an irregular shape, or need to be processed in larger batches that would not fit within the constraints of a narrow tube.

Key Differentiators in Application

While both furnaces heat materials to high temperatures, their geometric differences make them suitable for very different tasks. Your choice will depend entirely on whether your priority is precision control or sample capacity.

Precision Control: The Tube Furnace Advantage

The narrow, cylindrical shape of a tube furnace allows for superior temperature uniformity. Multi-zone models, which have two or three independently controlled heating areas along the tube's length, can create an exceptionally stable and precise temperature profile.

This design is also ideal for atmosphere management. The small internal volume and clear flow path from one end to the other make it easier to purge oxygen and maintain a consistent flow of process gas, which is critical for sensitive material synthesis or analysis.

Sample Size and Capacity: The Box Furnace Advantage

The clear strength of a box furnace is its ability to accommodate large, heavy, or awkwardly shaped samples. Its spacious chamber provides the flexibility needed for general-purpose heat treatment, ashing, or annealing of bulk materials.

This larger capacity also makes it ideal for high-throughput batch processing, where multiple samples can be loaded onto trays and heated simultaneously under the same conditions.

Understanding the Trade-offs

Selecting a furnace involves balancing competing priorities. Each design comes with inherent limitations that you must consider for your specific application.

Tube Furnace Limitation: The Size Constraint

The most significant drawback of a tube furnace is its limited sample diameter and length. It is inherently ill-suited for any process involving bulky items, restricting its use to smaller samples that can fit comfortably inside the working tube.

Box Furnace Limitation: The Control Compromise

While a box furnace can be equipped with ports for gas or vacuum, achieving the same level of atmospheric purity and precise control as a tube furnace is difficult. The large internal volume makes purging less efficient and establishing uniform gas flow more challenging. Likewise, managing precise temperature gradients across a large chamber is more complex.

Making the Right Choice for Your Process

Your decision should be guided by the primary requirement of your work. Analyze your sample and your process to determine which furnace geometry is the non-negotiable choice.

- If your primary focus is precise temperature profiling and atmospheric control: A tube furnace, especially a multi-zone model, is the superior choice for applications like crystal growth, chemical vapor deposition (CVD), or sensitive material synthesis.

- If your primary focus is processing large samples or high-throughput batches: A box furnace is the necessary tool for general annealing, hardening, ashing, or any heat treatment of bulky components.

- If your primary focus is general-purpose lab flexibility: A box furnace often provides more versatility for a lab that handles a wide variety of sample shapes and sizes with less stringent atmospheric demands.

By understanding that furnace geometry dictates its function, you can confidently select the tool that aligns perfectly with your specific scientific or industrial goal.

Summary Table:

| Feature | Tube Furnace | Box Furnace |

|---|---|---|

| Chamber Geometry | Long, narrow cylinder | Rectangular chamber |

| Ideal For | Precise temperature & atmosphere control | Large, bulky samples & batch processing |

| Key Advantage | Superior temperature uniformity & gas flow | High capacity & sample size flexibility |

| Common Applications | CVD, crystal growth, material synthesis | Annealing, ashing, general heat treatment |

Still Unsure Which Furnace is Right for Your Process?

KINTEK's expertise can guide you to the optimal solution. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces and Box (Muffle) Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements, whether you need ultimate precision or maximum capacity.

Contact our experts today for a personalized consultation and let us help you achieve superior results.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How is an industrial tube furnace utilized to evaluate the thermal stability of modified diamond powders?

- What is the significance of defining the quartz tube as a heat transfer boundary? Optimize Your Furnace Modeling

- What role does a horizontal tube furnace play in the carbonization of SiC-C preforms? Optimize Material Structural Yield

- What applications is a Split Tube Furnace (Single Zone) suitable for? Ideal for Uniform Heating and Easy Access

- Why is a precision tube furnace required for Nitrogen-doped SiOC synthesis? Ensure Perfect Structural Integrity

- What role does a tube furnace play in the hydrogenation process of Ti6Al4V alloys? Master Hydrogen Diffusion Control

- Why is high-purity nitrogen gas introduced into a vacuum tube furnace during cooling? Optimize Your Nitriding Process

- Why is a high-purity quartz tube used as the core reactor component in controlled combustion? Thermal and Optical Needs