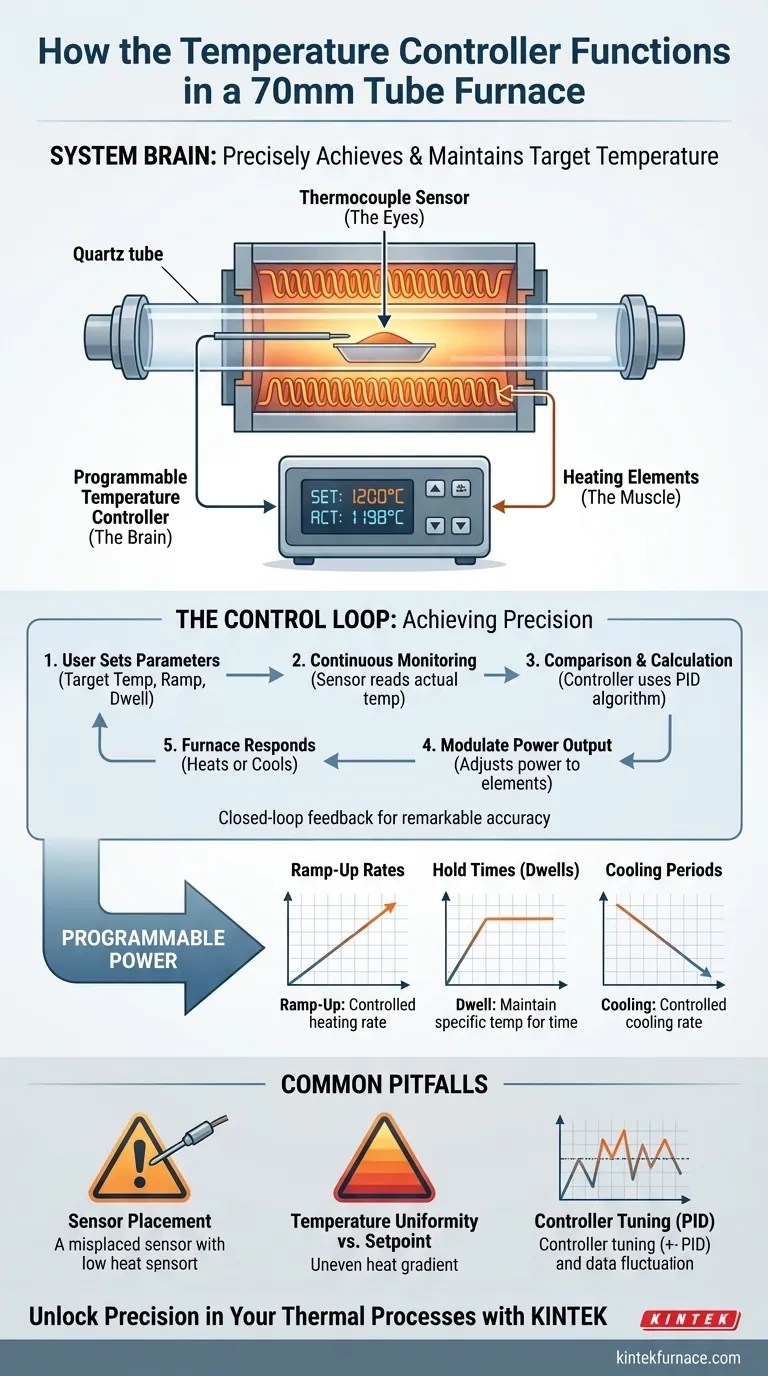

In a 70mm tube furnace, the temperature controller functions as the system's brain. It uses a sensor, typically a thermocouple, to continuously measure the actual temperature inside the furnace chamber. The controller then compares this real-time measurement to the desired temperature you have set and intelligently adjusts the electrical power sent to the heating elements, ensuring the furnace precisely achieves and maintains the target temperature.

The controller’s function is not merely to turn the heat on and off. It operates a sophisticated feedback loop, constantly modulating power to the heating elements. This capability enables the precise, programmable heating cycles required for advanced scientific research and material production.

The Core Components of Temperature Control

To understand the controller's function, it's helpful to see it as part of an integrated system. Each component has a distinct and critical role.

The Temperature Sensor (The "Eyes")

The system's eyes are a temperature sensor, such as a thermocouple or an RTD (Resistance Temperature Detector). This probe is placed inside the furnace to get an accurate reading of the thermal environment. It converts the detected heat into an electrical signal that the controller can interpret.

The Controller (The "Brain")

The controller is the central processing unit. It receives the signal from the temperature sensor and compares this "actual" temperature against the "setpoint" temperature programmed by the user. Based on the difference, it calculates the precise amount of power the heating elements need.

The Heating Elements (The "Muscle")

The heating elements are the components that do the physical work. They are made of a resistive material that converts electrical energy into heat. The controller delivers a specific amount of power to these elements, causing them to glow and radiate heat, which is then absorbed by the furnace tube and the sample inside.

The Furnace Body and Insulation (The "Environment")

The furnace's insulated body is not a passive component. High-quality insulation minimizes heat loss, which allows the controller to maintain a stable temperature with less energy. This insulation is also key to achieving good temperature uniformity across the furnace's central hot zone.

How the Control Loop Achieves Precision

The interaction between the sensor, controller, and heating elements creates a "closed-loop" control system. This process is dynamic and continuous.

Establishing the Setpoint

First, the user inputs all desired thermal parameters into the controller's interface. This includes the target temperature, the rate of heating, and how long to hold that temperature.

Continuous Monitoring and Comparison

Once the program starts, the controller begins its primary task. It continuously polls the thermocouple for the current temperature, comparing this value to the target setpoint for that moment in the cycle.

Modulating Power Output

If the measured temperature is below the setpoint, the controller increases the power supplied to the heating elements. If the temperature is above the setpoint, it reduces or cuts the power. This constant adjustment allows the system to follow a temperature profile with remarkable accuracy.

The Power of Modern Programmable Controllers

Modern digital controllers have moved far beyond simply holding a single temperature. Their programmability is what makes tube furnaces such powerful tools for material science and engineering.

Defining Ramp-Up Rates

Users can specify exactly how quickly the furnace should heat up, measured in degrees per minute or hour. This controlled ramp prevents thermal shock to sensitive materials and is crucial for many chemical processes.

Setting Hold Times (Dwells)

A controller can be programmed to maintain, or "dwell," at a specific temperature for a set period, from minutes to many hours. This is essential for processes like annealing, sintering, or catalyst activation that require a sample to be "soaked" at a high temperature.

Programming Cooling Periods

Just as important as heating, the rate of cooling can be controlled. This allows for slow, controlled crystallization or rapid quenching to lock in a specific material phase. A programmable controller can manage multiple heating, dwell, and cooling segments in a single, automated cycle.

Common Pitfalls and Considerations

While powerful, achieving perfect temperature control depends on understanding a few key factors.

Sensor Placement and Accuracy

The controller only knows the temperature at the tip of its sensor. If the sensor is placed incorrectly, it will not reflect the true temperature of your sample. Always ensure the thermocouple is positioned to accurately measure the temperature in the furnace's uniform hot zone.

Temperature Uniformity vs. Setpoint

The setpoint on your controller corresponds to a single point. The "hot zone" of a furnace is the length of the tube where the temperature is stable and uniform. This zone is always a key specification, as your sample must fit within it for consistent results.

Controller Tuning (PID)

Modern controllers use a PID (Proportional-Integral-Derivative) algorithm to minimize temperature overshoot and stabilize quickly at the setpoint. For very high-precision applications or unusual setups, these PID values may need to be "tuned" to optimize the controller's response and prevent temperature fluctuations.

Making the Right Choice for Your Application

When evaluating a tube furnace, the controller's capability is as important as the furnace's maximum temperature or size.

- If your primary focus is simple heat treatment or drying: A basic controller with single setpoint and simple hold functions may be sufficient.

- If your primary focus is material science research (e.g., phase transitions): You need a multi-segment programmable controller with precise control over ramp rates and multiple dwell stages.

- If your primary focus is advanced synthesis (e.g., nanomaterials, chemical vapor deposition): Prioritize a sophisticated controller that can manage complex thermal profiles and potentially integrate with gas flow or vacuum systems.

Ultimately, the temperature controller transforms a simple heater into a precise instrument for repeatable and sophisticated thermal processing.

Summary Table:

| Component | Function | Key Details |

|---|---|---|

| Temperature Sensor | Measures actual temperature | Uses thermocouple or RTD for accurate readings |

| Controller | Compares and adjusts power | Implements PID algorithm for stability |

| Heating Elements | Converts power to heat | Resistive materials for uniform heating |

| Furnace Body | Maintains stable environment | Insulation for temperature uniformity |

Unlock Precision in Your Thermal Processes with KINTEK

Are you working in material science, research, or advanced synthesis and need reliable high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnace systems tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by deep customization capabilities to meet your specific experimental requirements.

Experience enhanced efficiency, precise temperature control, and durable performance for applications like annealing, sintering, or catalyst activation. Contact us today to discuss how our solutions can optimize your lab's operations and drive your projects forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety