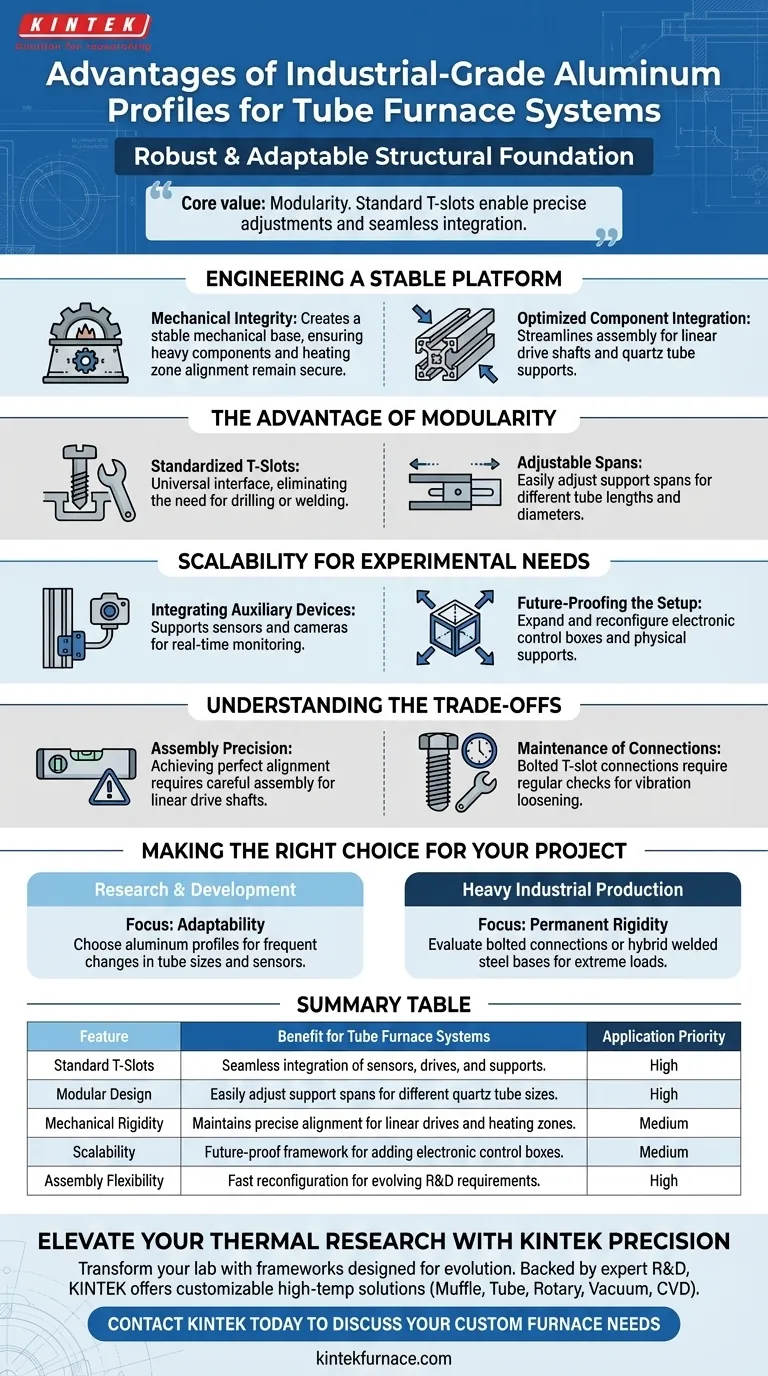

Industrial-grade aluminum profiles provide a robust and highly adaptable structural foundation for tube furnace systems. They deliver immediate mechanical stability while offering versatile mounting interfaces for essential components such as linear drive shafts, quartz tube supports, and electronic control units.

The core value of this material system is its modularity; standard T-slots enable precise adjustments and the seamless integration of new instruments, allowing the framework to evolve alongside your experimental requirements.

Engineering a Stable Platform

Mechanical Integrity

The profiles create a stable mechanical base, ensuring that the heavy and sensitive components of a furnace system remain secure during operation. This rigidity is critical for maintaining the alignment of the heating zone and the sample carrier.

Optimized Component Integration

The design specifically accommodates mounting interfaces for linear drive shafts and quartz tube supports without requiring complex custom fabrication. This streamlines the assembly process for the core mechanics of the furnace.

The Advantage of Modularity

Standardized T-Slots

The inclusion of standard T-slots acts as a universal interface for hardware and fasteners. This feature eliminates the need for drilling or welding when adding new components to the frame.

Adjustable Spans

Researchers can easily perform adjustments of support spans to accommodate tubes of different lengths or diameters. This flexibility is essential for labs that run various types of thermal experiments using a single infrastructure.

Scalability for Experimental Needs

Integrating Auxiliary Devices

The framework easily supports the addition of peripheral tools, such as sensors or cameras, for real-time process monitoring. These devices can be mounted anywhere along the profile grooves for optimal positioning.

Future-Proofing the Setup

This high level of customization and scalability ensures the setup remains useful as experimental parameters change. You can expand or reconfigure the electronic control boxes and physical supports without discarding the original frame.

Understanding the Trade-offs

Assembly Precision

While modularity is a strength, achieving perfect alignment requires careful assembly compared to pre-welded structures. You must ensure all connections are squared properly during the build to prevent binding in linear drive shafts.

Maintenance of Connections

Unlike welded steel frames, bolted T-slot connections can loosen over time if subjected to vibration. Regular checks of the fasteners are necessary to maintain the mechanical stability of the system.

Making the Right Choice for Your Project

To determine if aluminum profiles are the right fit for your tube furnace application, consider your operational goals:

- If your primary focus is Research and Development: Choose aluminum profiles for their adaptability, allowing you to frequently change tube sizes and add sensors without rebuilding the frame.

- If your primary focus is Heavy Industrial Production: Evaluate if the bolted connections provide sufficient permanent rigidity, or if a hybrid approach with welded steel bases is required for extreme loads.

Leveraging modular aluminum profiles transforms your furnace framework from a static structure into a dynamic experimental tool.

Summary Table:

| Feature | Benefit for Tube Furnace Systems | Application Priority |

|---|---|---|

| Standard T-Slots | Seamless integration of sensors, drives, and supports without welding. | High |

| Modular Design | Easily adjust support spans for different quartz tube sizes. | High |

| Mechanical Rigidity | Maintains precise alignment for linear drives and heating zones. | Medium |

| Scalability | Future-proof framework for adding electronic control boxes and cameras. | Medium |

| Assembly Flexibility | Fast reconfiguration for evolving R&D experimental requirements. | High |

Elevate Your Thermal Research with KINTEK Precision

Transform your laboratory setup with frameworks designed for evolution. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique experimental needs. Whether you require the modular adaptability of aluminum profiles for R&D or the robust stability of heavy industrial production, our engineering team is ready to deliver the perfect high-temp solution.

Ready to build a more flexible and efficient lab?

Contact KINTEK Today to Discuss Your Custom Furnace Needs

Visual Guide

References

- Casey Coffland, Elliott T. Gall. An open-source linear actuated-quartz tube furnace with programmable ceramic heater movement for laboratory-scale studies of combustion and emission. DOI: 10.2139/ssrn.5687995

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the core role of a tubular furnace in the direct pyrolysis of biomass into biochar? Master Carbon Engineering

- What is the function of a two-zone tube furnace in Borophene CVD? Achieve Precise Thermal Decoupling for 2D Synthesis

- How do split tube furnaces provide access to the chamber? Unlock Easy Sample Handling for Your Lab

- What is the primary purpose of using a tube furnace during the desizing phase? Optimize Carbon Fiber Surface Purity

- What are the typical physical and performance specifications for lab tube furnaces? A Guide to Key Specs

- What is the heating rate of a tube furnace? Balancing Speed with Safety for Your Lab

- How do high-temperature laboratory tube furnaces ensure environmental stability? Precision Thermal Reduction Tips

- What is the function of vacuum-sealed tubes and controlled heating? Master Ruthenium Precursor Embedding